Abstract

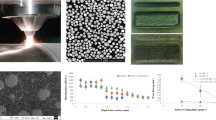

Pulsed plasma transferred arc surfacing is presently used in many industrial applications to make protective layers against corrosion, temperature exposition, and excessive wear. Increasing wear resistance is especially important in areas of industry where titanium alloys are used, such as aviation and cosmonautics, because the wear resistance of titanium alloys is often weak. One way to increase the wear resistance is to deposit or form a cermet with a titanium matrix (TMC) on the surface of the part. The present study deals with the fabrication and characterization of TMC based on B4C. TMC with B4C was formed by co-feeding Ti6Al4V and B4C powder into a melting pool. Two B4C powders with different grain size were mixed with Ti6Al4V matrix in two ratios. It has been found that the deposited, thick layers have dispersed B4C grains in the matrix. The B4C grains partially dissolve in the titanium matrix to form borides and carbides. The resulting structure of the deposits is formed by a matrix with dispersed TiCx and TiBw particles; in some clusters, a full transformation of Ti was observed, resulting in regions containing only borides and carbides. The deposits are metallurgically connected to the substrate—Ti6Al4V. The TMCs were investigated in terms of microstructure and chemical composition and phase composition. Indentation hardness and reduced elastic modulus of individual phases were assessed by nanoindentation modulus mapping. Friction coefficient was determined using the linear pin test.

Similar content being viewed by others

References

K. Holmberg and A. Erdemir, Influence of Tribology on Global Energy Consumption, Costs and Emissions, Friction, 2017, 5(3), p 263-284.

M. Kandeva, A. Vencl and D. Karastoyanov. Advanced Tribological Coatings For Heavy-Duty Applications: Case Studies. Marin Drinov Publishing House of Bulgarian Academy of Sciences, Sofia, 2016.

B.G. Mellor. Surface Coatings for Protection Against Wear. Woodhead Publishing, Cambridge, 2006, p 429.

K.C. Antony, J. Glenny, and J.E. Northwood. Hardfacing, Welding, Brazing and Soldering. Metals Handbook, American Society for Metals, 1983.

A.S.C.M. D’oliveira, R.S.C. Paredes, and R.L.C. Santos, Pulsed Current Plasma Transferred Arc Hardfacing, J. Mater. Process. Technol., 2006, 171(2), p 167-174. https://doi.org/10.1016/j.jmatprotec.2005.02.269

P. Rohan, T. Kramár, and J. Petr, HSS Deposition by PTA – Feasibility and Properties, Adv. Sci. Technol. Res. J., 2016, 10(29), p 57-61.

P. Rohan and M. Boxanová. Lecheng ZHANG a František LUKÁČ. High speed steel deposited by pulsed PTA – frequency influence. In: Proceedings of the Conference in Düsseldorf - ITSC 2017. 336. DVS Media GmbH, Dusseldorf, Germany, 2017, p. 4. ISBN 978-3-96144-000-9

D. Olson, ASM Handbook: Welding, Brazing, and Soldering: Welding, Brazing, and Soldering, Asm Intl, Ohio, 1993.

American Society for Metals. Properties and Selection: Nonferrous Alloys and Pure Metals, Vol. 2. Metals Park, Ohio, 1978.

G. Welsch, R. Boyer, and E.W. Collings, Materials Properties Handbook: Titanium Alloys: Titanium Alloys, ASM international, Ohio, 1993.

P. Kumar and K.S. Chandran, Strength–Ductility Property Maps of Powder Metallurgy (PM) Ti-6Al-4V Alloy: A Critical Review of Processing-Structure-Property Relationships: A Critical Review of Processing-Structure-Property Relationships, Metall. Mater. Trans. A, 2017, 48(5), p 2301-2319.

O. Ivasishin, D. Savvakin, F. Froes, and K. Bondareva, Synthesis of Alloy Ti-6Al-4V with Low Residual Porosity by a Powder Metallurgy Method, Powder Metall. Met. Ceram., 2002, 41(7–8), p 382-390.

L. Bolzoni, E. Ruiz-navas, and E. Gordo, Feasibility Study of the Production of Biomedical Ti–6Al–4V Alloy by Powder Metallurgy, Mater. Sci. Eng. C, 2015, 49, p 400-407.

L. Song, H. Xiao, J. Ye, and S. Li, Direct Laser Cladding of Layer-Band-Free Ultrafine Ti6Al4V Alloy, Surf. Coat. Technol., 2016, 307, p 761-771. https://doi.org/10.1016/j.surfcoat.2016.10.007

A. Antonysamy, Microstructure, Texture and Mechanical Property Evolution During Additive Manufacturing of Ti6Al4V Alloy for Aerospace Applications, The University of Manchester, United Kingdom, 2012.

B. Dutta and F. Froes, 24 - The Additive Manufacturing (AM) of Titanium Alloys, Butterworth-Heinemann, Boston, 2015, p 447-468

S. Jhavar, N.K. Jain, and C.P. Paul, Development of Micro-Plasma Transferred arc (μ-PTA) Wire Deposition Process for Additive Layer Manufacturing Applications, J. Mater. Process. Technol., 2014, 214(5), p 1102-1110. https://doi.org/10.1016/j.jmatprotec.2013.12.016

J.J. Lin, Y.H. Lv, Y.X. Liu, B.S. Xu, Z. Sun, Z.G. Li, and Y.X. Wu, Microstructural Evolution and Mechanical Properties of Ti-6Al-4V Wall Deposited by Pulsed Plasma Arc Additive Manufacturing, Mater. Des., 2016, 102, p 30-40. https://doi.org/10.1016/j.matdes.2016.04.018

F. Martina, J. Mehnen, S.W. Williams, P. Colegrove, and F. Wang, Investigation of the Benefits of Plasma Deposition for the Additive Layer Manufacture of Ti–6Al–4V, J. Mater. Process. Technol., 2012, 212(6), p 1377-1386. https://doi.org/10.1016/j.jmatprotec.2012.02.002

A. Molinari, G. Straffelini, B. Tesi, and T. Bacci, Dry Sliding Wear Mechanisms of the Ti6Al4V Alloy, Wear, 1997, 208(1), p 105-112. https://doi.org/10.1016/S0043-1648(96)07454-6

C. Martini and L. Ceschini, A Comparative Study of the Tribological Behaviour of PVD Coatings on the Ti-6Al-4V Alloy, Tribol. Int., 2011, 44(3), p 297-308.

G. Cassar, S. Banfield, J.C. Wilson, J. Housden, A. Matthews, and A. Leyland, Impact Wear Resistance of Plasma Diffusion Treated and Duplex Treated/PVD-Coated Ti–6Al–4V Alloy, Surf. Coat. Technol., 2012, 206(10), p 2645-2654.

O. Çelik, Microstructure and Wear Properties of WC Particle Reinforced Composite Coating on Ti6Al4V Alloy Produced by the Plasma Transferred Arc Method, Appl. Surf. Sci., 2013, 274, p 334-340.

M. Asadikiya, C. Zhang, C. Rudolf, B. Boesl, A. Agarwal, and Y. Zhong, The Effect of Sintering Parameters on Spark Plasma Sintering of B4C, Ceram. Int., 2017, 43(14), p 11182-11188.

K. Kim, J. Chae, J. Park, J. Ahn, and K. Shim, Sintering Behavior and Mechanical Properties of B4C Ceramics Fabricated by Spark Plasma Sintering, J. Ceram. Process. Res., 2009, 10(6), p 716-720.

J. Selvam, I. Dinaharan, and R. Rai. Matrix and Reinforcement Materials for Metal Matrix Composites. 2021. https://doi.org/10.1016/B978-0-12-803581-8.11890-9

R.E. Tressler, Structural and Thermostructural Ceramics, Elsevier, Oxford, 2001, p 8913-8921

I.G. Crouch, G.V. Franks, C. Tallon, S. Thomas, and M. Naebe, 7 - glasses and ceramics, Woodhead Publishing in Materials. Woodhead Publishing, Sawston, 2017, p 331-393

M. Rosso, Ceramic and Metal Matrix Composites: Routes and Properties: Routes and Properties, J. Mater. Process. Technol., 2006, 175(1), p 364-375.

S. Bahl, Fiber Reinforced Metal Matrix Composites - A Review, Mater. Today Proc., 2021, 39, p 317-323. https://doi.org/10.1016/j.matpr.2020.07.423

V. Mamedov, Spark Plasma Sintering as Advanced PM Sintering Method, Powder Metall., 2002, 45(4), p 322-328. https://doi.org/10.1179/003258902225007041

D.R. Ni, L. Geng, J. Zhang, and Z.Z. Zheng, Effect of B4C Particle Size on Microstructure of In Situ Titanium Matrix Composites Prepared by Reactive Processing of Ti–B4C System, Scr. Mater., 2006, 55(5), p 429-432.

P.A. Molian and L. Hualun, Laser Cladding of ti-6al-4v with bn for Improved Wear Performance, Wear, 1989, 130(2), p 337-352. https://doi.org/10.1016/0043-1648(89)90187-7

M. Hayat, H. Singh, Z. He, and P. Cao, Titanium Metal Matrix Composites: An Overview: An Overview, Compos. A Appl. Sci. Manuf., 2019, 121, p 418-438. https://doi.org/10.1016/j.compositesa.2019.04.005

P. Mendez, N. Barnes, K. Bell et al., Welding Processes for Wear Resistant Overlays, J. Manuf. Process., 2014, 16(1), p 4-25. https://doi.org/10.1016/j.jmapro.2013.06.011

T.R. Chapman, D.E. Niesz, R.T. Fox, and T. Fawcett, Wear-Resistant Aluminum–Boron–Carbide Cermets for Automotive Brake Applications, Wear, 1999, 236(1), p 81-87. https://doi.org/10.1016/S0043-1648(99)00259-8

Z.F. Zhang, L.C. Zhang, and Y.W. Mai, Wear of Ceramic Particle-Reinforced Metal-Matrix Composites - Part I Wear Mechanisms, J. Mater. Sci., 1995, 30(8), p 1961-1966. https://doi.org/10.1007/BF00353018

E. Pérez-Soriano, C. Arévalo Mora, and I. Montealegre-Meléndez, In situ titanium composites: XRD study of secondary phases tied to the processing conditions and starting materials: XRD study of secondary phases tied to the processing conditions and starting materials, High-Resolution Inelastic X-Ray Scattering. IntechOpen, London, 2019

H. Zhao and Y.-B. Cheng, Formation of TiB2–TiC Composites by Reactive Sintering, Ceram. Int., 1999, 25(4), p 353-358. https://doi.org/10.1016/S0272-8842(98)00048-0

B.-J. Choi and Y.-J. Kim, In-Situ (TiB+ TiC) Particulate Reinforced Titanium Matrix Composites: Effect of B 4 C Size and Content: Effect of B 4 C Size and Content, Met. Mater. Int., 2013, 19(6), p 1301-1307.

K. Zhang, X. Tian, M. Bermingham et al., Effects of Boron Addition on Microstructures and Mechanical Properties of Ti-6Al-4V Manufactured by Direct Laser Deposition, Mater. Des., 2019, 2019(184), p 108191. https://doi.org/10.1016/j.matdes.2019.108191

P. Jiang, X.L. He, X.X. Li, L.G. Yu, and H.M. Wang, Wear Resistance of a Laser Surface Alloyed Ti–6Al–4V Alloy, Surf. Coat. Technol., 2000, 130(1), p 24-28. https://doi.org/10.1016/S0257-8972(00)00680-0

M. Erinosho and E. Akinlabi, Influence of Laser Power on Improving the Wear Properties of Laser-Deposited Ti-6Al-4V+ B 4 C Composite, Stroj. Vest. J. Mech. Eng., 2018, 64(7–8), p 488-495.

M. Nartu, S. Mantri, M. Pantawane, Y.-H. Ho, B. Mcwilliams, K. Cho, N. Dahotre, and R. Banerjee, In Situ Reactions During Direct Laser Deposition of Ti-B4C Composites, Scr. Mater., 2020, 183, p 28-32.

S. Chen, A. Usta, and M. Eriten, Microstructure and Wear Resistance of Ti6Al4V Surfaces Processed by Pulsed Laser, Surf. Coat. Technol., 2017, 315, p 220-231. https://doi.org/10.1016/j.surfcoat.2017.02.031

L. Vály, D. Grech, E. Neubauer, M. Kitzmantel, L. Bača, and N. Stelzer, Preparation of titanium metal matrix composites using additive manufacturing, Key Engineering Materials. Trans Tech Publ, Switzerland, 2017

S. Risbud, J. Groza, and M. Kim, Clean Grain Boundaries in Aluminium Nitride Ceramics Densified without Additives by a Plasma-Activated Sintering Process, Philos. Mag. B, 1994, 69(3), p 525-533. https://doi.org/10.1080/01418639408240126

I. Montealegre-Melendez, C. Arévalo, E. Ariza, E. Pérez-Soriano, C. Rubio-Escudero, M. Kitzmantel, and E. Neubauer, Analysis of the Microstructure and Mechanical Properties of Titanium-Based Composites Reinforced by Secondary Phases and B4C Particles Produced via Direct Hot Pressing, Materials, 2017 https://doi.org/10.3390/ma10111240

C.A.C. Sequeira and L. Amaral, Role of Kirkendall Effect in Diffusion Processes in Solids, Trans. Nonferr. Met. Soc. China, 2014, 24(1), p 1-11. https://doi.org/10.1016/S1003-6326(14)63021-1

H.X. Li, Z.H. Zhong, A.K. Yang, Z.Q. Wang, Q. Wen, C. Chen, K.J. Song, and Y.C. Wu, Interfacial Microstructure Evolution and Mechanical Properties of B4C-Based Composite Joints Bonded with Ti Foil, Ceram. Int., 2018, 44(15), p 18016-18024. https://doi.org/10.1016/j.ceramint.2018.07.003

H. Izui, S. Komaki, and M. Okano, Mechanical Properties of TiB/Ti Composites by Spark Plasma Sintering, J. Solid Mech. Mater. Eng., 2008, 2(2), p 234-242. https://doi.org/10.1299/jmmp.2.234

S. Sun, M. Wang, L. Wang, J. Qin, W. Lu, and D. Zhang, The Influences of Trace TiB and TiC on Microstructure Refinement and Mechanical Properties of In Situ Synthesized Ti Matrix Composite, Compos. B Eng., 2012, 43(8), p 3334-3337. https://doi.org/10.1016/j.compositesb.2012.01.075

Acknowledgment

Authors acknowledge support from the ESIF EU Operational Programme Research, Development and Education and from the Center of Advanced Aerospace Technology (CZ.02.1.01/0.0/0.0/16_019/0000826), Faculty of Mechanical Engineering, Czech Technical University in Prague

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rohan, P., Lukáč, F., Kolaříková, M. et al. Pulsed Plasma Surfacing of Titanium Matrix Cermet Based on B4C. J Therm Spray Tech 31, 1975–1984 (2022). https://doi.org/10.1007/s11666-022-01421-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01421-0