Abstract

Fabric anisotropy and fines content (fc) in sands modify significantly their mechanical behaviour, particularly as related to static liquefaction under undrained conditions. The fabric anisotropy aspect, expressed by means of an evolving fabric tensor F, has been addressed in the recently developed Anisotropic Critical State Theory (ACST) that enhances the two critical state conditions on stress ratio (η) and void ratio (e) of the classical Critical State Theory by an additional condition on the critical state value of F in relation to loading direction; based on this concept it introduces the dependence of dilatancy on fabric anisotropy. Various models have been successfully developed within this framework for clean sands. The fc aspect has been addressed within the Equivalent Granular State Theory (EGST) that substitutes a properly defined equivalent granular void ratio (e*) for e in any model for clean sand in order to obtain the response of sand with fines without any other change of the model structure and constants. Along these lines, a constitutive model is constructed in this work in order to address the effect of both F and fc simultaneously, by a combination of these two powerful propositions. The idea is very simple: one takes a constitutive model developed within ACST for clean sands, hence it accounts for fabric anisotropy, and substitutes the e* for e, as well as the derivative quantities of such substitution, hence it accounts for fc. The result yields a model that can simulate data on the undrained response for a range of fc, with emphasis on static liquefaction. It is shown that the inclusion of fabric anisotropy improves previous similar simulations made within the EGST but without the framework of ACST.

Similar content being viewed by others

Abbreviations

- b :

-

Active fraction of fines in force structure of the soil skeleton

- e :

-

Global void ratio

- e 0 :

-

Global void ratio before shearing

- e* :

-

Equivalent granular void ratio

- e* 0 :

-

Equivalent granular void ratio before shearing

- e* SS :

-

Equivalent granular void ratio at steady state

- ε q :

-

Deviator strain

- ε v :

-

Volumetric strain

- F :

-

Fabric

- F in :

-

Initial fabric

- ψ :

-

State parameter

- ψ * :

-

Equivalent granular state parameter

- ψ * 0 :

-

Equivalent granular state parameter before shearing

- f c :

-

Fines content in decimal

- f thre :

-

Threshold fines content in decimal

- G* e :

-

Elastic shear modulus

- C g, n g :

-

Non-dimensional parameter in Eqs. (2) and (3), independent of fc

- h 1, h 2, n :

-

Parameters in Eq. (15), independent of fc

- K* e :

-

Elastic bulk modulus

- K* p :

-

Plastic hardening parameter

- ν :

-

Poisson ratio

- d :

-

Dilatancy

- ζ :

-

Dilatancy state parameter

- m, d 0 :

-

Parameter in Eq. (17), independent of fc

- p ′ :

-

Mean effective stress, p′ = (σ1′ + 2σ3′)/3

- q :

-

Deviator stress, q = (σ1′ − σ3′)

- σ 1′,σ 3′:

-

Major principal effectives stresses in triaxial condition

- η :

-

Stress ratio, q/p′

References

Baki MAL, Rahman MM, Lo SR, Gnanendran CT (2012) Linkage between static and cyclic liquefaction of loose sand with a range of fines contents. Can Geotech J 49(8):891–906. https://doi.org/10.1139/t2012-045

Baki MAL, Rahman MM, Lo SR (2014) Predicting onset of cyclic instability of loose sand with fines using instability curves. Soil Dyn Earthq Eng 61–62:140–151. https://doi.org/10.1016/j.soildyn.2014.02.007

Barnett N, Rahman MM, Karim MR, Nguyen HBK, Carraro JAH (2020) Equivalent state theory for sand with non-plastic fine mixtures: a DEM investigation. Geotechnique:Accepted. https://doi.org/10.1680/jgeot.19.p.103

Barnett N, Rahman MM, Karim MR, Nguyen HBK, Carraro JAH (2021) Equivalent state theory for mixtures of sand with non-plastic fines: a DEM investigation. Geotechnique 71(5):423–440. https://doi.org/10.1680/jgeot.19.P.103

Barnett N, Rahman MM, Karim MR, Nguyen HBK, Carraro JAH (2021) Equivalent state theory for mixtures of sand with non-plastic fines: a DEM investigation. Geotechnique:1–18. https://doi.org/10.1680/jgeot.19.P.103

Been K, Jefferies MG (1985) A state parameter for sands. Geotechnique 35(2):99–112

Bobei D (2004) Static Liquefaction of sand with a small amount of fines. PhD Thesis, University of New South Wales at Australian Defence Force Academy, Canberra, Australia

Bobei DC, Lo SR, Wanatowski D, Gnanendran CT, Rahman MM (2009) A modified state parameter for characterizing static liquefaction of sand with fines. Can Geotech J 46(3):281–295. https://doi.org/10.1139/T08-122

Chang CS, Meidani M (2012) Dominant grains network and behavior of sand–silt mixtures: stress–strain modeling. Int J Numer Anal Methods Geomech. https://doi.org/10.1002/nag.2152

Chang CS, Yin ZY (2011) Micromechanical modeling for behavior of silty sand with influence of fine content. Int J Solids Struct 48(19):2655–2667. https://doi.org/10.1016/j.ijsolstr.2011.05.014

Chen G, Wu Q, Zhao K, Shen Z, Yang J (2020) A binary packing material-based procedure for evaluating soil liquefaction triggering during earthquakes. J Geotech Geoenviron Eng 146(6):04020040. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002263

Chu J, Leong WK (2002) Effect of fines on instability behaviour of loose sand. Geotechnique 52(10):751–755

Dafalias YF (1986) Bounding surface plasticity. I: mathematical foundation and hypoplasticity. J Eng Mech 112(9):966–987. https://doi.org/10.1061/(ASCE)0733-9399(1986)112:9(966)

Dafalias YF, Manzari M (2004) Simple plasticity sand model accounting for fabric change effects. J Eng Mech 130(6):622–634. https://doi.org/10.1061/(ASCE)0733-9399(2004)130:6(622)

Dafalias YF, Papadimitriou A, Li XS (2004) Sand plasticity model accounting for inherent fabric anisotropy. J Eng Mech 130(11):1319–1333. https://doi.org/10.1061/(ASCE)0733-9399(2004)130:11(1319)

Dafalias YF, Taiebat M (2016) SANISAND-Z: zero elastic range sand plasticity model. Geotechnique 66(12):999–1013. https://doi.org/10.1680/jgeot.15.P.271

Fang H, Shen Y, Zhao Y (2019) Multishear bounding surface modelling of anisotropic sands accounting for fabric and its evolution. Comput Geotech 110:57–70. https://doi.org/10.1016/j.compgeo.2019.02.015

Fu P, Dafalias YF (2011) Fabric evolution within shear bands of granular materials and its relation to critical state theory. Int J Numer Anal Meth Geomech 35(18):1918–1948. https://doi.org/10.1002/nag.988

Gajo A, Wood M (1999) Trent sand: a kinematic-hardening constitutive model: the q-p formulation. Geotechnique 49(5):595–614. https://doi.org/10.1680/geot.1999.49.5.595

Gao Z, Zhao J, Li X-S, Dafalias YF (2014) A critical state sand plasticity model accounting for fabric evolution. Int J Numer Anal Meth Geomech 38(4):370–390. https://doi.org/10.1002/nag.2211

Georgiannou VN, Burland JB, Hight DW (1990) The undrained behaviour of clayey sands in triaxial compression and extension. Geotechnique 40(3):431–449

Goudarzy M, Rahman MM, König D, Schanz T (2016) Influence of non-plastic fines content on maximum shear modulus of granular materials. Soils Found 56(6):973–983. https://doi.org/10.1016/j.sandf.2016.11.003

Goudarzy M, Rahemi N, Rahman MM, Schanz T (2017) Predicting the maximum shear modulus of sands containing non-plastic fines. J Geotech Geoenviron Eng 143(9):1–5. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001760

Hardin BO, Richart FEJ (1963) Elastic wave velocities in granular soils. J Soil Mech Found Div ASCE 89(1):33–65

Ishihara K (1993) Liquefaction and flow failure during earthquakes. Geotechnique 43(3):351–415

Iwasaki T, Tatsuoka F (1977) Effects of grain size and grading on dynamic shear moduli of sands. Soils Found 17(3):19–35

Jefferies MG (1993) Nor-Sand: a simple critical state model for sand. Geotechnique 43(1):91–103

Jefferies M, Been K (2006) Soil liquefaction: a critical state approach. Taylor & Francis, London

Kenney TC (1977) Residual strength of mineral mixture. In: Proceedings of 9th international conference of soil mechanics and foundation engineering, Tokyo, pp 155–160

Kuerbis R, Negussey D (1988) Vaid YP Effect of gradation and fine content on the undrained response of sand. In: Zul DJAV, Vick SG (eds) Hydraulic fill structure, geotechnical special publication. ASCE, New York, pp 330–345

Lashkari A (2014) Recommendations for extension and re-calibration of an existing sand constitutive model taking into account varying non-plastic fines content. Soil Dyn Earthq Eng 61–62:212–238. https://doi.org/10.1016/j.soildyn.2014.02.012

Lashkari A, Latifi M (2008) A non-coaxial constitutive model for sand deformation under rotation of principal stress axes. Int J Numer Anal Meth Geomech 32(9):1051–1086. https://doi.org/10.1002/nag.659

Li XS, Dafalias YF (2000) Dilatancy for cohesionless soils. Geotechnique 50(4):449–460

Li X, Dafalias YF (2012) anisotropic critical state theory: role of fabric. J Eng Mech 138(3):263–275. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000324

Li XS, Dafalias YF (2020) Noncoaxiality between two tensors with application to stress rate decomposition and fabric anisotropy variable. J Eng Mech 146(3):04020004. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001730

Lo SR, Lee IK (1990) Response of granular soil along constant stress increment ratio path. J Geotech Eng 116(3):355–376

Lo SR, Chu J, Lee IK (1989) A technique for reducing membrane penetration and bedding errors. Geotech Test J 12(4):311–316

Lo SR, Rahman MM, Bobei DC (2010) Limited flow behaviour of sand with fines under monotonic and cyclic loading. Geomech Geoeng 5(1):15–25. https://doi.org/10.1080/17486020903452709

Manzari MT, Dafalias YF (1997) A critical state two-surface plasticity model for sands. Geotechnique 47(2):255–272

McGeary RK (1961) Mechanical packing of spherical particles. J Am Ceram Soc 44(10):513–522

Mitchell JK (1976) Fundamental of soil behaviour. 1st edition edn. Wiley

Mohammadi A, Qadimi A (2015) A simple critical state approach to predicting the cyclic and monotonic response of sands with different fines contents using the equivalent intergranular void ratio. Acta Geotech 10(5):587–606. https://doi.org/10.1007/s11440-014-0318-z

Nakata Y, Hyodo M, Murata H, Yasufuku N (1998) Flow deformation of sands subjected to principal stress rotation. Soils Found 38(2):115–128. https://doi.org/10.3208/sandf.38.2_115

Ni Q, Tan TS, Dasari GR, Hight DW (2004) Contribution of fines to the compressive strength of mixed soils. Geotechnique 54(9):561–569

Papadimitriou AG, Dafalias YF, Li XS (2014) Anisotropic sand model and fabric evolution until the critical state. In: Paper presented at the European conference on numerical methods in geotechnical engineering, Delft, Netherlands

Pitman TD, Robertson PK, Sego DC (1994) Influence of fines on the collapse of loose sands. Can Geotech J 31(5):728–739

Rahman MM (2009) Modelling the influence of fines on liquefaction behaviour. PhD Thesis, University of New South Wales at Australian Defence Force Academy, Canberra, Australia

Rahman MM (2021) The state of art on equivalent state theory for silty sands. In: Sitharam TG, Jakka R, Kolathayar S (eds) Latest developments in geotechnical earthquake engineering and soil dynamics. Springer Singapore, Singapore, pp 225–246. https://doi.org/10.1007/978-981-16-1468-2_11

Rahman MM, Lo SR (2007) Equivalent granular void ratio and state parameters for loose clean sand with small amount of fines. In: Paper presented at the 10th Australia New Zealand Conference on Geomechanics: Common Ground, Brisbane, Australia, 21–24 Oct 2007

Rahman MM, Lo SR (2008) The prediction of equivalent granular steady state line of loose sand with fines. Geomech Geoeng 3(3):179–190. https://doi.org/10.1080/17486020802206867

Rahman MM, Lo SR, Gnanendran CT (2008) On equivalent granular void ratio and steady state behaviour of loose sand with fines. Can Geotech J 45(10):1439–1456. https://doi.org/10.1139/T08-064

Rahman MM, Lo SR, Gnanendran CT (2009) Reply to discussion by Wanatowski, D. and Chu, J. on- On equivalent granular void ratio and steady state behaviour of loose sand with fines. Can Geotech J 46 (4):483–486. https://doi.org/10.1139/T09-025

Rahman MM, Lo SR, Gnanendran CT (2009) Reply to the discussion by Wanatowski and Chu on “On equivalent granular void ratio and steady state behaviour of loose sand with fines”. Can Geotech J 46 (4):483-486. https://doi.org/10.1139/T09-025

Rahman MM, Lo SR, Baki MAL (2011) Equivalent granular state parameter and undrained behaviour of sand-fines mixtures. Acta Geotech 6(4):183–194. https://doi.org/10.1007/s11440-011-0145-4

Rahman MM, Lo SR (2012) Predicting the onset of static liquefaction of loose sand with fines. J Geotech Geoenviron Eng 138(8):1037–1041. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000661

Rahman MM, Cubrinovski M, Lo SR (2012) Initial shear modulus of sandy soils and equivalent granular void ratio. Geomech Geoeng 7(3):219–226. https://doi.org/10.1080/17486025.2011.616935

Rahman M, Baki M, Lo S (2014) Prediction of undrained monotonic and cyclic liquefaction behavior of sand with fines based on the equivalent granular state parameter. Int J Geomech 14(2):254–266. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000316

Rahman MM, Lo S-CR, Dafalias YF (2014) Modelling the static liquefaction of sand with low-plasticity fines. Geotechnique 64(11):881–894. https://doi.org/10.1680/geot.14.P.079

Rahman MM, Lo SR (2014) Undrained behaviour of sand-fines mixtures and their state parameters. J Geotech Geoenviron Eng 140(7):04014036. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001115

Roscoe KH, Schofield MA, Worth CP (1958) On the yielding of soils. Geotechnique 8(1):22–53

Schofield A, Worth P (1968) Critical state soil mechanics. McGraw-Hill, London

Shen CK, Vrymoed JL, Uyeno CK (1977) The effect of fines on liquefaction of sands. In: Paper presented at the The 9th international conference on soil mechanics and foundation engineering, Tokyo

Sun JIN, Sundaresan S (2011) A constitutive model with microstructure evolution for flow of rate-independent granular materials. J Fluid Mech 682:590–616. https://doi.org/10.1017/jfm.2011.251

Suwal LP, Kuwano R (2012) Poisson’s ratio evaluation on silty and clayey sands on laboratory speicmens by flat disk shaped piezo-ceramic transducer. Bull Earthq Resist Struct 45:140–158

Theocharis AI, Vairaktaris E, Dafalias YF, Papadimitriou AG (2017) Proof of incompleteness of critical state theory in granular mechanics and its remedy. J Eng Mech 143(2):04016117

Theocharis AI, Vairaktaris E, Dafalias YF, Papadimitriou AG (2019) Necessary and sufficient conditions for reaching and maintaining critical state. Int J Numer Anal Meth Geomech 43(12):2041–2055. https://doi.org/10.1002/nag.2943

Thevanayagam S, Mohan S (2000) Intergranular state variables and stress-strain behaviour of silty sands. Geotechnique 50(1):1–23

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128(10):849–859

Troncoso JH, Verdugo R (1985) Silt content and dynamic behaviour of tailing sands. In: Proceedings of 11th international conference on soil mechanics and foundation engineering, pp 1311–1314

Verdugo R, Ishihara K (1996) The steady state of sandy soils. Soils Found 36(2):81–91

Wan RG, Guo PJ (2004) Stress dilatancy and fabric dependencies on sand behavior. J Eng Mech 130(6):635–645. https://doi.org/10.1061/(ASCE)0733-9399(2004)130:6(635)

Wang R, Cao W, Xue L, Zhang J-M (2021) An anisotropic plasticity model incorporating fabric evolution for monotonic and cyclic behavior of sand. Acta Geotech 16(1):43–65. https://doi.org/10.1007/s11440-020-00984-y

Wood DM, Belkheir K, Liu DF (1994) Strain softening and state parameter for sand modelling. Geotechnique 44(2):335–339

Yang ZX, Xu TT, Chen YN (2018) Unified modeling of the influence of consolidation conditions on monotonic soil response considering fabric evolution. J Eng Mech 144(8):04018073. https://doi.org/10.1061/(ASCE)EM.1943-7889.0001499

Yin Z-Y, Zhao J, Hicher P-Y (2014) A micromechanics-based model for sand-silt mixtures. Int J Solids Struct 51(6):1350–1363. https://doi.org/10.1016/j.ijsolstr.2013.12.027

Yoshimine M, Ishihara K, Vargas W (1998) Effects of principal stress direction and intermediate principal stress on undrained shear behaviour of sand. Soils Found 38(3):179–188

Zhao C-F, Kruyt NP (2020) An evolution law for fabric anisotropy and its application in micromechanical modelling of granular materials. Int J Solids Struct 196–197:53–66. https://doi.org/10.1016/j.ijsolstr.2020.04.007

Zhao J, Gao Z (2016) Unified anisotropic elastoplastic model for sand. J Eng Mech 142(1):04015056. https://doi.org/10.1061/(ASCE)EM.1943-7889.0000962

Zlatovic S, Ishihara K (1995) On the influence of nonplastic fines on residul strength. In: Paper presented at the Proceedings of IS-TOKY0'95/ the first international conference on earthquake geotechnical engineering/Tokyo/ 14–16 November 1995, Tokyo, Japan,

Acknowledgements

M. M. Rahman acknowledges Early Career Researcher – International Travel Award and Professional Experience Program (PEP) from ITEE, University of South Australia for Sabbatical in University California, Davis. Dr Rahman also acknowledges support from Y.F. Dafalias and the Department of Civil and Environmental Engineering, University California, Davis. Y. F. Dafalias acknowledges the support from the European Research Council under the European Union's Seventh Framework Program FP7-ERC-IDEAS Advanced Grant Agreement no. 290963 (SOMEF), Hellas, and the European Regional Development Fund under grant no. CZ.02·1·01/0·0/0·0/15-003/0000493, CeNDYNMAT, Czech Republic.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

Equivalent granular void ratio, e*

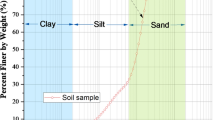

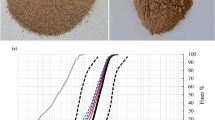

Rahman, Lo [50], by re-analysing the experimental data of McGeary [40] on binary packing studies and nine different sand-fines mixture from around the world, concluded that \(b\) entering Eq. (3) is a function of both fc and where Ds is the size of sand and df is the size of fines. Furthermore, the functional relationship, \(b = F\left( {f_{c} ,\chi } \right)\), has to possess a number of mathematical attributes [51]. To simulate the required attributes, Rahman and Lo [50] proposed a semi-empirical equation expressed as below.

where r = χ−1 = particle size ratio, df/DS and k = 1 − r0.25. Since sand and fines are generally not single-size materials, DS/df was generalized to DS,10/df,50 based on the argument in Ni et al. [44], where the subscripts denote fractile passing. fthre can be obtained from the experimental data, where available, as outlined in Rahman et al. [52]. However, as an initial approximation, fthre can be taken as 0.30, but it may be determined more reliably using the following equation developed by Rahman et al. [52].

The parameters α and β are determined by curve fitting to eight databases for χ in the range of 2 to 42, and this gave α = 0.50 and β = 0.13 [53]. The value of α and β in Eq. (29) has been evaluated with new emerging datasets by independent researchers, and general acceptability was observed [31, 42, 11] and used in many other studies [55, 59, 3]. Therefore, α = 0.5 and β = 0.13 are not material-dependent parameters; rather, they are fitting constant for many soils. Note DS,10 is 0.225 mm for Sydney sand and df,50 is 0.006 mm for the fines used in this study.

Rights and permissions

About this article

Cite this article

Rahman, M.M., Dafalias, Y.F. Modelling undrained behaviour of sand with fines and fabric anisotropy. Acta Geotech. 17, 2305–2324 (2022). https://doi.org/10.1007/s11440-021-01410-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01410-7