Abstract

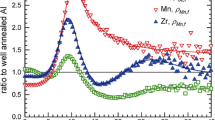

Precipitation reactions of the cast Al–3.4 at%Mg–2.7 at%Zn–0.80 at%Cu–0.10 at%Fe–0.05 at%Si alloy with and without addition of 0.14 at%Sc and 0.06 at%Zr were characterized by electrical resistometry, electron microscopy, X-ray diffraction, thermal analysis, microhardness testing, and positron annihilation. The AlMgZnCuScZr alloy contains a grain boundary T-phase (Mg32(Al,Cu,Zn)49) with a cubic and/or quasicrystalline structure. The AlMgZnCu alloy contains a mixture of MgZn2- and the T-phase. Primary multilayer Al3(Sc,Zr) particles precipitated during casting and subsequent cooling. The particles have a layered Al3(Sc,Zr) + α-Al + Al3(Sc,Zr) structure, i.e. consist of regions enriched with both Sc and Zr. Small atomic Mg,Zn(,Cu)-rich clusters coherent with the matrix were formed during the cooling of both alloys and/or in the course of their storage at ambient temperature. Their dissolution enables precipitation of the transient η′- and/or stable η-phases of the AlZnMgCu system in both investigated alloys. The effective activation energy for the dissolution of the clusters was calculated as ~ 103 kJ/mol. Annealing of the AlMgZnCuScZr alloy above 300 °C leads to a formation of the secondary Al3(Sc,Zr) particles which cause precipitation hardening and guarantee thermal stability of mechanical properties. Addition of Sc and Zr micro alloying elements resulted in a substantial grain refinement. The grain size remains unchanged up to isochronal annealing at 390 °C.

Graphic Abstract

Similar content being viewed by others

References

L.S. Toropova, D.G. Eskin, M.L. Kharakterova, T.V. Dobatkina, Advanced Aluminium Alloys Containing Scandium—Structure and Properties (Gordon and Breach Science Publisher, The Netherlands, 1998)

S. Chen, L. Jiyu, H. Gui-yun, C. Kanghua, H. Lanping, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.05.063

P. Lang, T. Wojcik, E. Povoden-Karadeniz, A. Falahati, E. Kozeschnik, J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2014.04.119

Z. Li, B. Xiong, Y. Zhang, B. Zhu, F. Wang, H. Liu, Mater. Charact. (2008). https://doi.org/10.1016/j.matchar.2007.01.006

K.R. Prasanta, M.M. Ghosh, K.S. Ghosh, Mater. Charact. (2015). https://doi.org/10.1016/j.matchar.2015.03.025

K.S. Ghosh, N. Gao, M.J. Starink, Mater. Sci. Eng. A (2012). https://doi.org/10.1016/j.msea.2012.05.026

Y. Wang, Z. Li, B. Xiong, K. Wen, S. Huang, X. Li, Y. Zhang, Metal. Mater. Int. (2019). https://doi.org/10.1007/s12540-018-00210-1

M.J. Starink, S.C. Wang, Acta Mater. (2003). https://doi.org/10.1016/S1359-6454(03)00363-X

X.B. Yang, J.H. Chen, J.Z. Liu, F. Qin, J. Xie, C.L. Wu, J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2014.04.185

W. Yang, S. Ji, M. Wang, Z. Li, J. Alloys Compd. (2014). https://doi.org/10.1016/j.jallcom.2014.05.061

W.X. Shu, L.G. Hou, C. Zhang, F. Zhang, J.C. Liu, J.T. Liu, L.Z. Zhuang, J.S. Zhang, Mater. Sci. Eng. A (2016). https://doi.org/10.1016/j.msea.2016.01.039

P.A. Rometsch, Y. Zhang, S. Khight, Trans. Nonferrous Met. Soc. China (2014). https://doi.org/10.1016/S1003-6326(14)63306-9

M. Zhang, T. Liu, C. He, J. Ding, E. Liu, C. Shi, J. Li, N. Zhao, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2015.10.296

J. Tang, H. Chen, X. Zhang, S. Liu, W. Liu, H. Ouyang, H. Li, Trans. Nonferrous Met. Soc. China (2012). https://doi.org/10.1016/S1003-6326(11)61313-7

M. Vlach, V. Kodetova, B. Smola, J. Cizek, T. Kekule, M. Cieslar, H. Kudrnova, L. Bajtosova, M. Leibner, I. Prochazka, Kovove Mater. (2018). https://doi.org/10.4149/km_2018_6_367

P. Priya, D.R. Johnson, M.J.M. Krane, Comput. Mater. Sci. (2017). https://doi.org/10.1016/j.commatsci.2017.08.008

P. Montagné, M. Tillard, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2015.09.201

N.Q. Vo, D.C. Dunand, D.N. Seidman, Mater. Sci. Eng. A (2016). https://doi.org/10.1016/j.msea.2016.09.065

M. Slapakova, B. Krivska, J. Bajer, O. Gryndin, M. Stolbchenko, M. Cieslar, Acta Phys. Pol. A (2018). https://doi.org/10.12693/APhysPolA.134.871

M. Kolar, V. Očenášek, J. Uhlíř, I. Stulíková, B. Smola, M. Vlach, V. Neubert, K. Šperlink, Mater. Sci. Forum (2008). https://doi.org/10.4028/www.scientific.net/MSF.567-568.357

M. Vlach, B. Smola, I. Stulikova, V. Ocenasek, Int. J. Mater. Res. (2009). https://doi.org/10.3139/146.110022

N.A. Belov, E.A. Naumova, T.K. Akopyan, V.V. Doroshenko, J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.05.281

W. Lefebvre, F. Danoix, H. Hallem, B. Forbord, A. Bostel, K. Martinsen, J. Alloys Compd. (2009). https://doi.org/10.1016/j.jallcom.2008.02.043

Z. Yin, Q. Pan, Y. Zhang, F. Jiang, Mater. Sci. Eng. A (2000). https://doi.org/10.1016/S0921-5093(99)00682-6

W.G. Zhang, Y.C. Ye, L.J. He, P.J. Li, X. Feng, L.S. Novikov, Mater. Sci. Eng. A (2013). https://doi.org/10.1016/j.msea.2013.04.067

S. Costa, H. Puga, J. Barbosa, A.M.P. Pinto, Mater. Des. (2012). https://doi.org/10.1016/j.matdes.2012.06.019

V.G. Davydov, T.D. Rostova, V.V. Zakharov, Y.A. Filatov, V.I. Yelagin, Mater. Sci. Eng. A (2000). https://doi.org/10.1016/S0921-5093(99)00652-8

M.S. Kaiser, S. Datta, A. Roychowdhury, M.K. Banerjee, Mater. Charact. (2008). https://doi.org/10.1016/j.matchar.2008.03.006

M. Vlach, J. Čížek, B. Smola, O. Melikhova, M. Vlček, V. Kodetová, H. Kudrnová, P. Hruška, Mater. Charact. (2017). https://doi.org/10.1016/j.matchar.2017.04.017

Y. Deng, Z. Yin, Q. Pan, G. Xu, Y. Duan, Y. Wang, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2016.10.094

A. De Luca, D.N. Seidman, D.C. Dunand, Acta Mater. (2019). https://doi.org/10.1016/j.actamat.2018.11.031

P. Okle, J.D. Lin, T. Zhu, D.C. Dunand, D.N. Seidman, Mater. Sci. Eng. A (2019). https://doi.org/10.1016/j.msea.2018.10.058

M. Vlach, I. Stulikova, B. Smola, H. Cisarova, J. Piesova, S. Danis, R. Gemma, J. Malek, D. Tanprayoon, V. Neubert, Int. J. Mater. Res. (2012). https://doi.org/10.3139/146.110712

S. Zhou, Z. Zhang, M. Li, D. Pan, H. Su, X. Du, P. Li, Y. Wu, Mater. Des. (2016). https://doi.org/10.1016/j.matdes.2015.10.132

S. Zhou, Z. Zhang, M. Li, D. Pan, H. Su, X. Du, P. Li, Y. Wu, Mater. Lett. (2016). https://doi.org/10.1016/j.matlet.2015.10.072

S. Zhou, Z. Zhang, M. Li, D. Pan, H. Su, X. Du, P. Li, Y. Wu, Mater. Charact. (2016). https://doi.org/10.1016/j.matchar.2016.05.011

J.H. Li, M. Wiessner, M. Alby, S. Wurster, B. Sartory, F. Hofer, P. Schumacher, Mater. Charact. (2015). https://doi.org/10.1016/j.matchar.2015.01.018

C. Xu, R. Du, X. Wang, S. Hanada, H. Yamagata, W. Wang, C. Ma, Trans. Nonferrous Met. Soc. China (2014). https://doi.org/10.1016/S1003-6326(14)63366-5

K.B. Hyde, A.F. Norman, P.B. Prangnell, Acta Mater. (2001). https://doi.org/10.1016/S1359-6454(01)00050-7

A.F. Norman, P.B. Prangnell, R.S. McEwen, Acta Mater. (1998). https://doi.org/10.1016/S1359-6454(98)00257-2

M. Hájek, J. Veselý, M. Cieslar, Mater. Sci. Eng. A (2007). https://doi.org/10.1016/j.msea.2006.01.175

J. Čížek, J. Mater. Sci. Technol. (2018). https://doi.org/10.1016/j.jmst.2017.11.050

R. Krause-Rehberg, H.S. Leipner, Positron Annihilation in Semiconductors (Springer, Berlin, 1999)

A. Somoza, M.P. Petkov, K.G. Lynn, A. Dupasquier, Phys. Rev. B (2002). https://doi.org/10.1103/PhysRevB.65.094107

F. Bečvář, J. Čížek, I. Procházka, J. Janotová, Nucl. Instrum. Methods A (2005). https://doi.org/10.1016/j.nima.2004.09.031

J. Čížek, M. Vlček, I. Procházka, Nucl. Instrum. Methods Phys. Res. A (2010). https://doi.org/10.1016/j.nima.2010.07.046

M.J. Starink, Thermochim. Acta (2004). https://doi.org/10.1016/S0040-6031(03)00144-8

N.Q. Chinh, J. Lendvai, D.H. Ping, K. Hono, J. Alloys Compd. (2004). https://doi.org/10.1016/j.jallcom.2003.11.175

M. Dellah, M. Bournane, K.A. Ragab, Y. Sadaoui, A.F. Sirenko, Mater. Des. (2013). https://doi.org/10.1016/j.matdes.2013.02.078

C. Antonione, F. Marino, G. Riontino, S. Abis, E. Russo, Mater. Chem. Phys. (1988). https://doi.org/10.1016/0254-0584(88)90055-7

V. Kodetová, M. Vlach, B. Smola, T. Kekule, S. Daniš, H. Kudrnová, J. Málek, Acta Phys. Pol. A (2018). https://doi.org/10.12693/APhysPolA.134.631

M. Murayama, K. Hono, Acta Mater. (1999). https://doi.org/10.1016/S1359-6454(99)00033-6

T.M. Hall, A.N. Goland, C.L. Snead, Phys. Rev. B (1974). https://doi.org/10.1103/PhysRevB.10.3062

M. Liu, J. Čížek, C.S.T. Chang, J. Banhart, Acta Mater. (2015). https://doi.org/10.1016/j.actamat.2015.02.019

N. Afify, A.F. Gaber, G. Abbady, Mater. Sci. Appl. (2011). https://doi.org/10.4236/msa.2011.25056

S. Abis, G. Riontino, Mater. Lett. (1987). https://doi.org/10.1016/0167-577X(87)90060-7

J. Buha, R.N. Lumley, A.G. Crosky, Mater. Sci. Eng. A (2008). https://doi.org/10.1016/j.msea.2008.02.039

J.C. Werenskiold, A. Deschamps, Y. Bréchet, Mater. Sci. Eng. A (2000). https://doi.org/10.1016/S0921-5093(00)01247-8

S.V. Emani, J. Benedyk, P. Nash, D. Chen, J. Mater. Sci. (2009). https://doi.org/10.1007/s10853-009-3879-8

Acknowledgements

This work was supported by The Czech Science Foundation (GACR), Project 17-17139S. The authors are also grateful to Ivana Stulíková, Tamara Čučková and Bohumil Smola for their help. PH acknowledges support by ERDF under the project CZ.02.1.01/0.0/0.0/15_003/0000485.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vlach, M., Čížek, J., Kodetová, V. et al. Annealing Effects in Cast Commercial Aluminium Al–Mg–Zn–Cu(–Sc–Zr) Alloys. Met. Mater. Int. 27, 995–1004 (2021). https://doi.org/10.1007/s12540-019-00499-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00499-6