Abstract

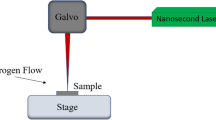

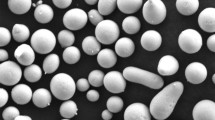

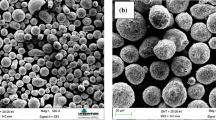

Plasma sprayed W-based coatings have the potential application as joining interlayers for the plasma-facing components of future fusion reactors. Particularly in the form of tungsten-steel functionally graded materials (FGMs), they would reduce the stress concentration between the W-based plasma-facing armor and steel-based construction. For mechanical integrity, good adhesion is essential. For this, conventional grit blasting treatment of the substrate may not be sufficient. Therefore, alternative treatments capable of reaching significantly higher roughness without damaging the substrate are sought. In this study, the effects of laser texturing on the adhesion of plasma sprayed W and W-steel FGMs on W and steel substrates are investigated. A variety of surface profiles were achieved by controlled laser ablation in several types of patterns. Their geometric features were systematically varied and measured, and the extent of their filling by the coating material was evaluated. On the most promising patterns, coating adhesion tests were performed in shear loading mode and the best performing patterns were identified. Significant improvement over grit-blasted surface was obtained on patterned surfaces with a high effective contact area, promoting mechanical interlocking. On steel substrates, generally higher adhesion was observed, surpassing already the coating cohesive strength; this is attributed to a combination of mechanical interlocking and metallurgical bonding.

Similar content being viewed by others

References

G. Pintsuk, Tungsten as a Plasma-Facing Material, Comprehensive Nuclear Materials, R.J.M. Konings, Ed., Elsevier, New York, 2012,

T. Weber, M. Stueber, S. Ulrich, R. Vassen, W.W. Basuki, J. Lohmiller, W. Sittel, and J. Aktaa, Functionally Graded Vacuum Plasma Sprayed and Magnetron Sputtered Tungsten/Eurofer97 Interlayers for Joints in Helium-Cooled Divertor Components, J. Nucl. Mater., 2013, 436(1-3), p 29-39

S. Heuer, J.W. Coenen, G. Pintsuk, J. Matějíček, M. Vilémová, and Ch. Linsmeier, Overview of Challenges and Developments in Joining Tungsten and Steel for Future Fusion Reactors, Phys. Scr., 2019, in press

J. Matějíček, P. Chráska, and J. Linke, Thermal Spray Coatings for Fusion Applications—Review, J. Therm. Spray Technol., 2007, 16(1), p 64-83

S. Heuer, J. Matějíček, M. Vilémová, M. Koller, K. Illková, J. Veverka, T. Weber, G. Pintsuk, J.W. Coenen, and C. Linsmeier, Atmospheric Plasma Spraying of Functionally Graded Steel/Tungsten Layers for the First Wall of Future Fusion Reactors, Surf. Coat. Technol., 2019, 366, p 170-178

M. Mellali, P. Fauchais, and A. Grimaud, Influence of Substrate Roughness and Temperature on the Adhesion/Cohesion of Alumina Coatings, Surf. Coat. Technol., 1996, 81(2-3), p 275-286

Y.Y. Wang, C.J. Li, and A. Ohmori, Influence of Substrate Roughness on the Bonding Mechanisms of High Velocity Oxy-Fuel Sprayed Coatings, Thin Solid Films, 2005, 485(1-2), p 141-147

M. Vilémová, J. Siegl, J. Matějíček, and R. Mušálek, Effect of the Grit Blasting Exposure Time on the Adhesion of Al2O3 and 316L Coatings, Proceedings of International Thermal Spray Conference, Hamburg, DVS-German Welding Society, 2011, p 1001-1006

J. Matějíček, M. Vilémová, R. Mušálek, P. Sachr, and J. Horník, The Influence of Interface Characteristics on the Adhesion/Cohesion of Plasma Sprayed Tungsten Coatings, Coatings, 2013, 3, p 108-125

W. Nowak, D. Naumenko, G. Mor, F. Mor, D.E. Mack, R. Vassen, L. Singheiser, and W.J. Quadakkers, Effect of Processing Parameters on MCrAlY Bondcoat Roughness and Lifetime of APS-TBC Systems, Surf. Coat. Technol., 2014, 260, p 82-89

G.S. Cho and K.H. Choe, Characterization of Plasma-Sprayed Tungsten Coating on Graphite With Intermediate Layers, Surf. Coat. Technol., 2012, 209, p 131-136

D. Braun, C. Greiner, J. Schneider, and P. Gumbsch, Efficiency of Laser Surface Texturing in the Reduction of Friction Under Mixed Lubrication, Tribol. Int., 2014, 77, p 142-147

S. Houdkova, P. Sperka, M. Repka, J. Martan, and D. Moskal, Shifted Laser Surface Texturing for Bearings Applications, J. Phys. Conf. Ser., 2017, 843, p 012076

A.Y. Vorobyev and C.L. Guo, Multifunctional Surfaces Produced by Femtosecond Laser Pulses, J. Appl. Phys., 2015, 117(3), p 033103

J.T. Cardoso, A.I. Aguilar-Morales, S. Alamri, D. Huerta-Murillo, F. Cordovilla, A.F. Lasagni, and J.L. Ocana, Superhydrophobicity on Hierarchical Periodic Surface Structures Fabricated via Direct Laser Writing and Direct Laser Interference Patterning on an Aluminium Alloy, Opt. Lasers Eng., 2018, 111, p 193-200

J. Yang, F.F. Luo, T.S. Kao, X. Li, G.W. Ho, J.H. Teng, X.G. Luo, and M.H. Hong, Design and Fabrication of Broadband Ultralow Reflectivity Black Si Surfaces by Laser Micro/Nanoprocessing, Light Sci. Appl., 2014, 3, p e185

G. Thomas, R. Vincent, G. Matthews, B. Dance, and P.S. Grant, Interface Topography and Residual Stress Distributions in W Coatings for Fusion Armour Applications, Mater. Sci. Eng. A, 2008, 477(1-2), p 35-42

R. Kromer, S. Costil, J. Cormier, D. Courapied, L. Berthe, P. Peyre, and M. Boustie, Laser Surface Patterning to Enhance Adhesion of Plasma Sprayed Coatings, Surf. Coat. Technol., 2015, 278, p 171-182

R. Kromer, J. Cormier, and S. Costil, Role of Powder Granulometry and Substrate Topography in Adhesion Strength of Thermal Spray Coatings, J. Therm. Spray Technol., 2016, 25(5), p 933-945

R. Kromer, S. Costil, J. Cormier, L. Berthe, P. Peyre, and D. Courapied, Laser Patterning Pretreatment Before Thermal Spraying: A Technique to Adapt and Control the Surface Topography to Thermomechanical Loading and Materials, J. Therm. Spray Technol., 2016, 25(3), p 401-410

R. Kromer, F. Mauget, L. Despres, S. Costil, and J. Cormier, Thermo-mechanical Fatigue Evaluation of a Thermal Barrier Coating Bond-Coatless System, Mater. Sci. Eng. A, 2019, 756, p 130-141

H. Greuner, H. Bolt, B. Boswirth, S. Lindig, W. Kuhnlein, T. Huber, K. Sato, and S. Suzuki, Vacuum Plasma-Sprayed Tungsten on Eurofer and 316L: Results of Characterisation and Thermal Loading Tests, Fusion Eng. Des., 2005, 75-79, p 333-338

T. Emmerich, D.D. Qu, R. Vassen, and J. Aktaa, Development of W-Coating With Functionally Graded W/Eurofer-Layers for Protection of First-Wall Materials, Fusion Eng. Des., 2018, 128, p 58-67

D. Qu, E. Gaganidze, R. Vassen, and J. Aktaa, Determination of Interface Toughness of Functionally Graded Tungsten/Eurofer Multilayer at 550 Degrees C by Analytical and Experimental Methods, Eng. Fract. Mech., 2018, 202, p 487-499

EN 15340, Thermal Spraying—Determination of Shear Load Resistance of Thermally Sprayed Coatings, European Committee for Standardization, Brussels, 2007

J. Martan, D. Moskal, and M. Kucera, Laser Surface Texturing with Shifted Method: Functional Surfaces at High Speed, J. Laser Appl., 2019, 31(2), p 022507

D. Moskal, J. Martan, and M. Kučera, Shifted Laser Surface Texturing (sLST) in Burst Regime, Proceedings of the 19th International Symposium on Laser Precision Microfabrication, (Edinburgh), Association of Industrial Laser Users (AILU) at Heriot-Watt University, 2018, p OR7

D. Moskal, J. Martan, M. Kucera, S. Houdkova, and R. Kromer, Picosecond Laser Surface Cleaning of AM1 Superalloy, Phys. Procedia, 2016, 83, p 249-257

J. Matějíček, M. Vilémová, B. Nevrlá, L. Kocmanová, J. Veverka, M. Halasová, and H. Hadraba, The Influence of Substrate Temperature and Spraying Distance on the Properties of Plasma Sprayed Tungsten and Steel Coatings Deposited in a Shrouding Chamber, Surf. Coat. Technol., 2017, 318, p 217-223

J. Matějíček, V. Weinzettl, E. Dufková, V. Piffl, and V. Peřina, Plasma Sprayed Tungsten-Based Coatings and Their Usage in Edge Plasma Region of Tokamaks, Acta Tech. CSAV, 2006, 51(2), p 179-191

S. Heuer, T. Weber, G. Pintsuk, J.W. Coenen, J. Matejicek, and C. Linsmeier, Aiming at Understanding Thermo-mechanical Loads in the First Wall of DEMO: Stress–Strain Evolution in a Eurofer–Tungsten Test Component Featuring a Functionally Graded Interlayer, Fusion Eng. Des., 2018, 135, p 141-153

J. Matějíček, R. Mušálek, and J. Veverka, Materials and Processing Factors Influencing Stress Evolution and Mechanical Properties of Plasma Sprayed Coatings, Surf. Coat. Technol., 2019, 366, p 170-178

J. Matejicek, S. Sampath, D. Gilmore, and R. Neiser, In Situ Measurement of Residual Stresses and Elastic Moduli in Thermal Sprayed Coatings—Part 2: Processing Effects on Properties of Mo Coatings, Acta Mater., 2003, 51(3), p 873-885

C.X. Sun, S.M. Wang, W.H. Guo, W.P. Shen, and C.C. Ge, Bonding Interface of W-CuCrZr Explosively Welded Composite Plates for Plasma Facing Components, J. Mater. Sci. Technol., 2014, 30(12), p 1230-1234

W.Q. Kong, X.F. Li, B.Y. Chen, C.Y. Wang, H.J. Chu, Y.T. Chen, P. Hua, and W. Zhou, Microstructure and Mechanical Properties of Diffusion Bonded W/MA956 Steel Joints With a Titanium Interlayer by SPS, J. Adhes. Sci. Technol., 2019, 33(17), p 1847-1857

W. Krauss, J. Lorenz, J. Konys, W. Basuki, and J. Aktaa, Thermomechanical Characterization of Joints for Blanket and Divertor Application Processed by Electrochemical Plating, Fusion Eng. Des., 2016, 109, p 1280-1285

S. Dallaire, Influence of Temperature on the Bonding Mechanism of Plasma-Sprayed Coatings, Thin Solid Films, 1982, 95(3), p 237-244

Acknowledgments

This work has been carried out within the framework of the EUROfusion Consortium and has received funding from the Euratom Research and Training Programme 2014-2018 under Grant Agreement No 633053. Support by Czech Science Foundation (Grant No. GA17-23154S), by the Czech Academy of Sciences (Strategy AV21 programme) and by the Ministry of Education, Youth and Sports of the Czech Republic (OP RDI Program, CENTEM Project, No. CZ.1.05/2.1.00/03.0088, co-funded by the ERDF; ITI II Program, LABIR-PAV Project, No. CZ.02.1.01/0.0/0.0/18_069/0010018) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Matějíček, J., Vilémová, M., Moskal, D. et al. The Role of Laser Texturing in Improving the Adhesion of Plasma Sprayed Tungsten Coatings. J Therm Spray Tech 28, 1346–1362 (2019). https://doi.org/10.1007/s11666-019-00924-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00924-7