Abstract

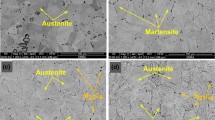

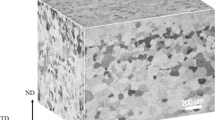

The influence of rolling temperatures performed at ambient and cryogenic conditions in the interval of deformations ε = <10; 50> (%) on structural development and mechanical properties of steel grade AISI 316LN was studied. The evaluations of microstructures were studied by optical and transmission electron microscopy. The initial strength properties of the material after solution annealing tested at 293 K were: RP0,2 = 325 MPa, Rm = 640 MPa, and A5 = 49%. The biggest values of strength properties were obtained by material processing at cryorolling conditions with thickness reduction of 50% and tested at 77 K as follows: RP0,2 = 1571 MPa, Rm = 1880 MPa, and A5 = 4%. From the analysis, it is resulted that the dislocation slip is the main mechanism of plastic deformation realized by rolling at ambient temperatures; at cryogenic temperatures, it is possible to observe a combination of dislocation slip accompanied with deformation twinning.

Similar content being viewed by others

References

J. Sas, S. Kauffmann-Weiss, and K.-P. Weiss, Effect of Aging on Mechanical Properties of 316LN at 4.2 K for Fusion Applications, Acta Metall. Slovaca, 2018, 24, p 287–295. https://doi.org/10.12776/ams.v24i4.1140

K.-P. Weiss, N. Bagrets, J. Sas, A. Jung, S.I. Schlachter, A. Della Corte, G. Celentano, and T. Kvačkaj, Mechanical and Thermal Properties of Central Former Material for High-Current Superconducting Cables, IEEE Trans. Appl. Superconduct., 2016, 26, p 7457353. https://doi.org/10.1109/tasc.2016.2539101

J.R. Davis, Alloy Digest Sourcebook: Stainless Steels. ASM International, 2000, ISBN: 978-0-87170-649-2

ASM Handbook: Properties and Selection: Irons, Steels, and High Performance Alloys. Volume 1, 2005, ISBN 0-87170-380-7

M.F. McGuire, Stainless Steels for Design Engineers. ASM International, 2008, ISBN: 0871707179

M.L.G. Byrnes, M. Grujicic, and W.S. Owen, Nitrogen Strengthening of a Stable Austenitic Stainless Steel, Acta Mater., 1987, 35(7), p 1853–1862

V.S.A. Challa, X.L. Wan, M.C. Somani, L.P. Karjalainen, and R.D.K. Misra, Strain Hardening Behavior of Phase Reversion-Induced Nanograined/Ultrafine-Grained (NG/UFG) Austenitic Stainless Steel and Relationship with Grain Size and Deformation Mechanism, Mater. Sci. Eng., A, 2014, 613, p 60–70

Y. Xiong, Y. Yuec, Y. Lu, T. He, M. Fan, F. Ren, and W. Cao, Cryorolling Impacts on Microstructure and Mechanical Properties of AISI316 LN Austenitic Stainless Steel, Mater. Sci. Eng., A, 2018, 709, p 270–276

A. Sato, K. Soma, and T. Mori, Hardening Due to Pre-existing ε-Martensite in an Fe-30Mn-1Si alloy single crystal, Acta Mater., 1982, 30, p 1901–1907

V. Seetharaman, Deformation and Martensite Transformation, Bull. Mater. Sci., 1984, 6, p 703–716

J. Manjanna, S. Kobayashi, Y. Kamada, S. Takahashi, and H. Kikuchi, Martensitic Transformation in SUS 316LN Austenitic Stainless Steel at RT, J. Mater. Sci., 2008, 43, p 2659–2665

D. Šimčák, T. Kvačkaj, R. Kočiško, R. Bidulský, J. Kepič, and V. Puchý, Evaluation of Hight Purity Aluminium After Asymmetric Rolling at Ambient and Cryogenic Temperatures, Acta Metall. Slovaca, 2017, 23, p 99–104. https://doi.org/10.12776/ams.v23i2.928

D. Hradil, M. Duchek, T. Hrbáčková, and A. Ciski, Gas nitriding with Deep Cryogenic Treatment of High-Speed Steel, Acta Metall. Slovaca, 2018, 24, p 187–193. https://doi.org/10.12776/ams.v24i2.1058

M. Sehri, H. Ghayour, K. Amini, M. Naseri, H. Rastegari, and V. Javaeri, Effects of Cryogenic Treatment on Microstructure and Wear Resistance of Fe-0.35C-6.3Cr Martensitic Steel, Acta Metall. Slovaca, 2018, 24, p 134–146. https://doi.org/10.12776/ams.v24i2.1037

T. Kvackaj, J. Bidulska, R. Bidulsky, A. Kovačova, R. Kocisko, P. Bella, M. Luptak, and J. Bacso, Influence of Annealing Conditions on Structural Development of Cryo Rolled FeSi Steel, Acta Phys. Pol., A, 2014, 126, p 184–185. https://doi.org/10.12693/APhysPolA.126.184

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma, Effect of Nanocrystalline and Ultrafine Grain Sizes on the Strain Rate Sensitivity and Activation Volume: fcc Versus bcc Metals, Mater. Sci. Eng., A, 2004, 381, p 71–79. https://doi.org/10.1016/j.msea.2004.03.064

T. Kvackaj, R. Kočiško, J. Tiža, J. Bidulská, A. Kovácová, R. Bidulský, J. Bacsó, and M. Vlado, Application of Workability Test to SPD Processing, Arch. Metall. Mater., 2013, 58, p 407–412. https://doi.org/10.2478/amm-2013-0008

T. Kvackaj, P. Bella, R. Bidulsky, R. Kocisko, P. Petrousek, A. Fedorikova, J. Bidulska, J. Jandacka, M. Luptak, M. Cernik, and R. Pernis, The Effect of Cryo-Rolling and Annealing on Magnetic Properties in Non-oriented Electrical Steel, Acta Phys. Pol., A, 2017, 131(4), p 1105–1107. https://doi.org/10.12693/APhysPolA.131.1105

I. Ucok, T. Ando, and N.J. Grant, Property Enhancement in Type 316L Stainless Steel by Spray Forming, Mater. Sci. Eng, 1991, A133, p 284–287

Y. Xiong, T. He, J. Wang, Y. Lu, L. Chen, F. Ren, Y. Liu, and A. Volinsky, Cryorolling Effect on Microstructure and Mechanical Properties of Fe-25Cr-20Ni Austenitic Stainless Steel, Mater. Des., 2018, 88, p 398–405. https://doi.org/10.1016/j.matdes.2015.09.029

B. Roy, R. Kumar, and J. Das, Effect of Cryorolling on the Microstructure and Tensile Properties of Bulk Nano-Austenitic Stainless Steel, Mater. Sci. Eng., A, 2015, 631, p 241–247. https://doi.org/10.1016/j.msea.2015.02.050

W. Wei, S.L. Wang, K.X. Wei, I.V. Alexandrov, Q.B. Du, and J. Hu, Microstructure and Tensile Properties of Cu-Al Alloys Processed by ECAP and Rolling at Cryogenic Temperature, J. Alloys Compd., 2016, 678, p 506–510. https://doi.org/10.1016/j.jallcom.2016.04.035

Acknowledgment

This work was supported by VEGA project 1/0599/18 and “Center of research of efficient integration of combined systems based on renewable energy sources” ITMS 26220220064, financed through European Regional Development Fund.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kvackaj, T., Rozsypalova, A., Kocisko, R. et al. Influence of Processing Conditions on Properties of AISI 316LN Steel Grade. J. of Materi Eng and Perform 29, 1509–1514 (2020). https://doi.org/10.1007/s11665-020-04561-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04561-y