Abstract

Background

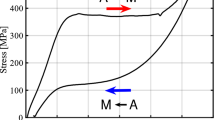

Shape memory alloys (SMAs) are phase transforming materials featuring strong thermomechanical couplings. Infrared thermography and heat source reconstruction (HSR) enable to track the calorific signature of deformation processes.

Objective

The objective was to characterize the transformation processes in a superelastic nickel-titanium SMA wire subjected to a force-controlled superelastic tensile cycle.

Methods

In-situ recorded thermographs were converted into spatiotemporal maps of heat sources using an in-house developed post-processing method based on the heat diffusion equation resolved numerically for unknown heat sources.

Results

Sequentially appearing patterns of localized transformation events of four types were identified and associated with martensite bands nucleations and their subsequent merging upon tensile loading. Analogically, the events associated with austenite bands nucleations and their subsequent merging were identified upon unloading. In addition, weak heat sources observed before and after the localized transformation events were associated with the homogeneous martensitic transformation.

Conclusions

The intrinsic dissipation heat associated with the nucleation and merging events is estimated to be ~ 25% of the released/absorbed latent heat.

Similar content being viewed by others

References

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Lagoudas DC (2010) Shape memory alloys: Modeling and engineering applications. Springer Science, New York

Lexcellent C (2013) Shape-memory alloys handbook. Wiley, Hoboken

Yoneyama T, Miyazaki S (2009) Shape memory alloys for biomedical applications. Woodhead Publishing, Cambridge

Racek J, Stora M, Šittner P, Heller L, Kopeček J, Petrenec M (2015) Monitoring tensile fatigue of superelastic NiTi wire in liquids by electrochemical potential. shap mem superelasticity 1:204–230. https://doi.org/10.1007/s40830-015-0020-5

Miyazaki S, Imai T, Otsuka K, Suzuki Y (1981) Lüders-like deformation observed in the transformation pseudoelasticity of a Ti-Ni alloy. Scr Metall 15:853–856. https://doi.org/10.1016/0036-9748(81)90265-9

Shaw JA, Kyriakides S (1995) Thermomechanical aspects of NiTi. J Mech Phys Solids 43:1243–1281. https://doi.org/10.1016/0022-5096(95)00024-D

Shaw JA, Kyriakides S (1997) Initiation and propagation of localized deformation in elasto-plastic strips under uniaxial tension. Int J Plasticity 13:837–871. https://doi.org/10.1016/S0749-6419(97)00062-4

Sittner P, Liu Y, Novak V (2005) On the origin of Lüders-like deformation of NiTi shape memory alloys. J Mech Phys Solids 53:1719–1746. https://doi.org/10.1016/J.JMPS.2005.03.005

Dutta SC, Majumder R (2019) Shape Memory Alloy (SMA) as a potential damper in structural vibration control. In: Hloch S, Al (eds) Advances in Manufacturing Engineering and Materials. Lecture Notes in Mechanical Engineering. Springer, Cham, pp 485–492. https://doi.org/10.1007/978-3-319-99353-9_51

Daly S, Ravichandran G, Bhattacharya K (2007) Stress-induced martensitic phase transformation in thin sheets of Nitinol. Acta Mater 55:3593–3600. https://doi.org/10.1016/j.actamat.2007.02.011

Pieczyska EA, Gadaj SP, Nowacki WK, Tobushi H (2004) Thermomechanical investigations of martensitic and reverse transformations in TiNi shape memory alloy. B Pol Acad Sci-Tech 52:165–171. http://www.ippt.pan.pl/Repository/o6480.pdf

Pieczyska EA, Gadaj SP, Nowacki WK, Tobushi H (2006) Phase-transformation fronts evolution for stress- and strain-controlled tension tests in TiNi shape memory alloy. Exp Mech 46:531–542. https://doi.org/10.1007/s11340-006-8351-y

Pieczyska EA (2010) Activity of stress-induced martensite transformation in TiNi shape memory alloy studied by infrared technique. J Mod Optic 57:1700–1707. https://doi.org/10.1080/09500341003725748

He Y, Sun Q (2014) On non-monotonic rate dependence of stress hysteresis of superelastic shape memory alloy bars. Int J Solids Struct 48:1688–1695. https://doi.org/10.1016/j.ijsolstr.2011.02.017

Takeda K, Tobushi H, Pieczyska EA (2012) Transformation-induced creep and creep recovery of shape memory alloy. Materials 5:909–921. https://doi.org/10.3390/ma5050909

Pieczyska EA, Tobushi H, Kulasiński K (2013) Development of transformation bands in TiNi SMA for various stress and strain rates studied by a fast and sensitive infrared camera. Smart Mater Struct 22:035007. https://doi.org/10.1088/0964-1726/22/3/035007

Yin H, He Y, Sun Q (2014) Effect of deformation frequency on temperature and stress oscillations in cyclic phase transition of NiTi shape memory alloy. J Mech Phys Solids 67:100–128. https://doi.org/10.1016/J.JMPS.2014.01.013

Ahadi A, Sun Q (2014) Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi. Acta Mater 76:186–197. https://doi.org/10.1016/j.actamat.2014.05.007

Pieczyska EA, Staszczak M, Dunić V, Slavković R, Tobushi H, Takeda K (2014) Development of stress-induced martensitic transformation in TiNi shape memory alloy. J Mater Eng Perform 23:2505–2514. https://doi.org/10.1007/s11665-014-0959-y

Alarcon E, Heller L, Chirani SA, Sittner P, Kopecek J, Saint-Sulpice L, Calloch S (2017) Fatigue performance of superelastic NiTi near stress-induced martensitic transformation. Int J Fatigue 95:76–89. https://doi.org/10.1016/j.ijfatigue.2016.10.005

Dunić V, Pieczyska EA, Kowalewski ZL, Matsui R, Slavković R (2019) Experimental and numerical investigation of mechanical and thermal effects in TiNi SMA during transformation-induced creep phenomena. Materials 12:883. https://doi.org/10.3390/ma12060883

Jury A, Balandraud X, Heller L, Alarcon E, Karlik M (2020) One-dimensional heat source reconstruction applied to phase transforming superelastic Ni-Ti wire. In: Baldi A et al. (Eds.) Residual Stress, Thermomechanics & Infrared Imaging and Inverse Problems, vol 6, Conference Proceedings of the Society for Experimental Mechanics Series, pp 36–40, Springer, Cham. https://doi.org/10.1007/978-3-030-30098-2_6

Balandraud X, Chrysochoos A, Leclercq S, Peyroux R (2001) Influence of the thermomechanical coupling on the propagation of a phase change front. C R Acad Sci- Ser IIB - Mech 329:621–626. https://doi.org/10.1016/S1620-7742(01)01376-9

Delpueyo D, Balandraud X, Grédiac M (2011) Applying infrared thermography to analyse martensitic microstructures in a Cu-Al-Be shape-memory alloy subjected to a cyclic loading. Mater Sci Eng A 528:8249–8258. https://doi.org/10.1016/J.MSEA.2011.07.050

Louche H, Schlosser P, Favier D, Orgéas L (2012) Heat source processing for localized deformation with non-constant thermal conductivity. Application to superelastic tensile tests of NiTi shape memory alloys. Exp Mech 52:1313–1328. https://doi.org/10.1007/s11340-012-9607-3

Chrysochoos A, Chezeaux J-C, Caumon H (1989) Thermomechanical behavior law analysis by infrared thermography. Rev Phys Appl 24:215–225. https://doi.org/10.1051/rphysap:01989002402021500

Schlosser P, Louche H, Favier D, Orgeas L (2007) Image processing to estimate the heat sources related to phase transformations during tensile tests of NiTi tubes. Strain 43:260–271. https://doi-org.insis.bib.cnrs.fr/https://doi.org/10.1111/j.1475-1305.2007.00350.x

Favier D, Louche H, Schlosser P, Orgeas L, Vacher P, Debove L (2007) Homogeneous and heterogeneous deformation mechanisms in an austenitic polycrystalline Ti-50.8 at.% Ni thin tube under tension. Investigation via temperature and strain fields measurements. Acta Mater 55:5310–5322. https://doi.org/10.1016/j.actamat.2007.05.027

Chrysochoos A, Löbel M, Maisonneuve O (1995) Thermomechanical coupling of pseudoelastic behavior of CuZnAl and NiTi alloys. C R Acad Sci II 320(5):217–223

Delobelle V (2012) Contributions à l’étude thermomécanique des alliages à mémoire de forme NiTi et à la réalisation par soudage de matériaux architecturés NiTi. PhD dissertation, Université de Grenoble, France

De Oliveira HMR (2018) Study of thermomechanical couplings in nanostructured superelastic nickel-titanium wires. PhD dissertation, Université de Grenoble, France

Brinson LC, Schmidt I, Lammering R (2004) Stress-induced transformation behavior of a polycrystalline NiTi shape memory alloy: micro and macromechanical investigations via in situ optical microscopy. J Mech Phys Solids 52:1549–1571. https://doi.org/10.1016/J.JMPS.2004.01.001

He YJ, Sun QP (2010) Rate-dependent domain spacing in a stretched NiTi strip. Int J Solids Struct 47:2775–2783. https://doi.org/10.1016/J.IJSOLSTR.2010.06.006

Sedmák P, Pilch J, Heller L, Kopeček J, Wright J, Sedlák P, Frost M, Šittner P (2016) Grain-resolved analysis of localized deformation in nickel-titanium wire under tensile load. Science 353:559–562. https://doi.org/10.1126/science.aad6700

Zheng L, He Y, Moumni Z (2016) Effects of Lüders-like bands on NiTi fatigue behaviors. Int J Solids Struct 83:28–44. https://doi.org/10.1016/J.IJSOLSTR.2015.12.021

Heller L, Šittner P, Sedlák P, Seiner H, Tyc O, Kadeřávek L, Sedmák P, Vronka M (2019) Beyond the strain recoverability of martensitic transformation in NiTi. Int J Plasticity 116:232–264. https://doi.org/10.1016/J.IJPLAS.2019.01.007

Dunić V, Pieczyska EA, Tobushi H, Staszczak M, Slavković R (2014) Experimental and numerical thermo-mechanical analysis of shape memory alloy subjected to tension with various stress and strain rates. Smart Mater Struct 23:055026. https://doi.org/10.1088/0964-1726/23/5/055026

Chrysochoos A, Louche H (2000) An infrared image processing to analyse the calorific effects accompanying strain localisation. Int J Eng Sci 38:1759–1788. https://doi.org/10.1016/S0020-7225(00)00002-1

Louche H, Chrysochoos A (2001) Thermal and dissipative effects accompanying Lüders band propagation. Mater Sci Eng A 307:15–22. https://doi.org/10.1016/S0921-5093(00)01975-4

Wattrisse B, Muracciole JM, Chrysochoos A (2002) Thermomechanical effects accompanying the localized necking of semi-crystalline polymers. Int J Therm Sci 41:422–427. https://doi.org/10.1016/S1290-0729(02)01334-0

Connesson N, Maquin F, Pierron F (2011) Experimental energy balance during the first cycles of cyclically loaded specimens under the conventional yield stress. Exp Mech 51, 23–44. https://doi-org.insis.bib.cnrs.fr/https://doi.org/10.1007/s11340-010-9336-4

Blanche A, Chrysochoos A, Ranc N, Favier V (2015) Dissipation assessments during dynamic very high cycle fatigue tests. Exp Mech 55: 699–709. https://doi-org.insis.bib.cnrs.fr/https://doi.org/10.1007/s11340-014-9857-3

Delobelle V, Favier D, Louche H, Connesson N (2015) Determination of local thermophysical properties and heat of transition from thermal fields measurement during drop calorimetric experiment. Exp Mech 55: 711–723. https://doi-org.insis.bib.cnrs.fr/https://doi.org/10.1007/s11340-014-9877-z

Ranc N, Blanche A, Ryckelynck D, Chrysochoos A (2015) POD preprocessing of IR thermal data to assess heat source distributions. Exp Mech 55:725–739. https://doi.org/10.1007/s11340-014-9858-2

Wang XG, Wang L, Huang MX (2017) Kinematic and thermal characteristics of Lüders and Portevin-Le Châtelier bands in a medium Mn transformation-induced plasticity steel. Acta Mater 124:17–29. https://doi.org/10.1016/J.ACTAMAT.2016.10.069

Jongchansitto P, Douellou C, Preechawuttipong I, Balandraud X (2019) Comparison between 0D and 1D approaches for mechanical dissipation measurement during fatigue tests. Strain 55:e12307. https://doi.org/10.1111/str.12307

Chrysochoos A, Pham H, Maisonneuve O (1996) Energy balance of thermoelastic martensite transformation under stress. Nucl Eng Des 162:1–12. https://doi.org/10.1016/0029-5493(95)01140-4

Delpueyo D, Balandraud X, Grédiac M, Stanciu S, Cimpoesu N (2018) A specific device for enhanced measurement of mechanical dissipation in specimens subjected to long-term tensile tests in fatigue. Strain 54:e12252. https://doi.org/10.1111/str.12252

Pastor ML, Balandraud X, Grédiac M, Robert JL (2008) Applying infrared thermography to study the heating of 2024-T3 aluminium specimens under fatigue loading. Infrared Phys Technol 51:505–515. https://doi.org/10.1016/J.INFRARED.2008.01.001

Pottier T, Louche H, Samper S, Favreliere H, Toussaint F, Vacher P (2014) Proposition of a modal filtering method to enhance heat source computation within heterogeneous thermomechanical problems. Int J Eng Sci 81:163–176. https://doi.org/10.1016/J.IJENGSCI.2014.04.010

Delpueyo D, Balandraud X, Grédiac M (2013) Heat source reconstruction from noisy temperature fields using an optimised derivative Gaussian filter. Infrared Phys Technol 60:312–322. https://doi.org/10.1016/J.INFRARED.2013.06.004

Corvec G, Robin E, Le Cam JB, Sangleboeuf JC, Lucas P (2016) Improving spatio-temporal resolution of infrared images to detect thermal activity of defect at the surface of inorganic glass. Infrared Phys Technol 77:193–202. https://doi.org/10.1016/J.INFRARED.2016.05.026

Beitone C, Balandraud X, Delpueyo D, Grédiac M (2017) Heat source reconstruction from noisy temperature fields using a gradient anisotropic diffusion filter. Infrared Phys Technol 80:27–37. https://doi.org/10.1016/J.INFRARED.2016.11.003

Witkin AP (1987) Scale-space filtering. In: Fischle AM, Firschein O (eds) Readings in Computer Vision. Elsevier. Chapter 2, pp 329–332. https://doi.org/10.1016/B978-0-08-051581-6.50036-2

Renault N, André S, Maillet D, Cunat C (2010) A spectral method for the estimation of a thermomechanical heat source from infrared temperature measurements. Int J Therm Sci 49:1394–1406. https://doi.org/10.1016/J.IJTHERMALSCI.2010.03.001

Chrysochoos A, Surrel Y (2012) Basics of Metrology and introduction to techniques. In: Grédiac M, Hild F (Eds) Full-Field Measurements and Identification in Solid Mechanics. Wiley, Hoboken, Chap. 1, pp 1–30. https://doi.org/10.1002/9781118578469.ch1

Philippi I, Batsale JC, Maillet D, Degiovanni A (1995) Measurement of thermal diffusivities through processing of infrared images. Rev Sci Instrum 66:182–192. https://doi.org/10.1063/1.1146432

Rohde M, Schüssler A (1997) On the response-time behaviour of laser micromachined NiTi shape memory actuators. Sensors Actuat A-Phys 61:463–468. https://doi.org/10.1016/S0924-4247(97)80306-8

Faulkner MG, Amalraj JJ, Bhattacharyya A (2000) Experimental determination of thermal and electrical properties of Ni-Ti shape memory wires. Smart Mater Struct 9:632–639. https://doi.org/10.1088/0964-1726/9/5/307

Zanotti C, Giuliani P, Riva G, Tuissi A, Chrysanthou A (2009) Thermal diffusivity of Ni-Ti SMAs. J Alloys Compd 473:231–237. https://doi.org/10.1016/J.JALLCOM.2008.05.040

Zanotti C, Giuliani P, Chrysanthou A (2012) Martensitic-Austenitic phase transformation of Ni–Ti SMAs: Thermal properties. Intermetallics 24:106–114. https://doi.org/10.1016/J.INTERMET.2012.01.026

Meyer GH (2015) Chap. 2: The Method of Lines (MOL) for the diffusion equation. In: The time-discrete method of lines for options and bonds. World Scientific Publishing Co. Pte. Ltd., Singapore, pp 57–74. https://doi.org/10.1142/9789814619684_0002

Šittner P, Landa M, Lukáš P, Novák V (2006) R-phase transformation phenomena in thermomechanically loaded NiTi polycrystals. Mech Mater 38:475–492. https://doi.org/10.1016/J.MECHMAT.2005.05.025

De Oliveira HMR, Louche H, Grassi END, Favier D (2020) Specific forward/reverse latent heat and martensite fraction measurement during superelastic deformation of nanostructured NiTi wires. Mater Sci Eng A 774:138928. https://doi.org/10.1016/j.msea.2020.138928

Shaw J, Churchill C, Iadicola MA (2008) Tips and tricks for characterizing shape memory alloy wire: Part 1 - Differential scanning calorimetry and basic phenomena. Exp Techniques 32:55–62. https://doi.org/10.1111/j.1747-1567.2008.00410.x

Acknowledgements

This publication was supported by OP RDE, MEYS, under the project “European Spallation Source - participation of the Czech Republic - OP”, “Reg. No. CZ.02.1.01/0.0/0.0/16_013/0001794”. P. Šittner and L. Heller kindly acknowledge the support of the research from Czech Science Foundation (CSF) project 18-03834S. M. Karlik acknowledges the financial support of the ERDF in the frame of the Project No. CZ.02.1.01/0.0/0.0/15_003/0000485. Finally, A. Jury acknowledges the support received from the Agence Nationale de la Recherche of the French government through the program ‘‘Investissements d’Avenir’’ (16-IDEX-0001 CAP 20–25).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interests

The authors declare that they have no conflict of interest

Rights and permissions

About this article

Cite this article

Jury, A., Balandraud, X., Heller, L. et al. Reconstruction of Heat Sources Induced in Superelastically Loaded Ni-Ti Wire By Localized Deformation Processes. Exp Mech 61, 349–366 (2021). https://doi.org/10.1007/s11340-020-00648-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00648-8