Abstract

A peeling test known as the “Scotch Tape test” has been used for more than 40 years in conservation practice for assessing the consolidation efficiency of degraded stone. However, the method has not been supported by any standard or reliably verified recommendations for its application. Its applicability is overestimated, and its unrestricted use without adequate knowledge and sufficient understanding can lead to non-comparable, non-reproducible and, in many cases, incorrect and severely biased results and assessments. This paper presents the results of a recent study focused on establishing limits for application, reliable procedures and a “standard” protocol for testing the cohesion characteristics of brittle and quasi-brittle materials, mainly mortars and stones. The main application strategy exploits repeated peeling in the same place on a surface in order to eliminate the effect of the natural decrease in the detached material from the subsurface layers, which might be incorrectly interpreted as a consolidation effect. There is a discussion of factors influencing the performance of the peeling test method, and examples of peeling measurements on various natural and artificial stones are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction and objectives

In situ testing of the surface cohesion of brittle and quasi-brittle heterogeneous materials suffers from a lack of suitable non-destructive methods. The problem is mainly important when assessing surface degradation characteristics and/or when evaluating the effectiveness of consolidation treatment of degraded historic materials.

One of the methods recommended for this purpose is the so-called Scotch Tape test or peeling test. The Scotch Tape test method was originally suggested and used for testing the adhesion of a coating or paint layer to a substrate, and it is defined as a method for evaluating the adhesion of a coating to a substrate. Pressure-sensitive tape is applied to an area of the coating which is sometimes cross-hatched with scratched lines. Footnote 1 Adhesion is considered to be adequate if the coating is not pulled off by the tape when it is removed Footnote 2 [1].

The method was probably introduced into the field of conservation for testing the cohesion qualities of historic materials, mainly stone and renders, by Mora and Torraca in the 1960s [2]. However, no standards or reliably verified recommendations are available for this type of application in conservation practice. Unrestricted use without adequate knowledge and sufficient understanding can lead to non-comparable and non-reproducible as well as in many cases incorrect and severely biased results and assessments.

A study of the basic performance characteristics and features of application of the so-called peeling test method on quasi brittle composites was therefore carried out within the research programme of the STONECORE project.Footnote 3 It aimed at establishing limits for application, reliable procedures and a “standard” protocol for testing the cohesion characteristics of brittle and quasi-brittle materials, mainly mortars and stones. This paper presents an introduction to the peeling test procedures, and proposes recommendations for performing peeling tests on historic stone surfaces and for evaluating the results that are obtained.

2 State of art review

There are few systematic literature references on the application of peeling tests in conservation. In most of the works, only a general or superficial description of the measurement procedure has been found, and a detailed description of the peeling test application is mostly missing, e.g. in [3].

In general, the cohesion of a surface layer is roughly assessed by measuring the amount of material stuck to a flexible adhesive tape which was attached to the surface and then removed. Because Scotch Tape is most frequently used, the method is also known as the Scotch Tape test, or as the Tape Test.Footnote 4

Dei and Baglioni with their collaborators used the method for testing the consolidation effect on a calcareous stone called Pietra di Nanto [4]. They used 3 M transparent Scotch Tape cut into pieces not less than 2 cm in length and with a contact surface area of about 4 cm2. The weight of the piece of Scotch Tape was calculated as an average of 10 pieces. During the tests, the cut piece was pressed to the test surface, and after 3 min it was peeled off using steel pincers. Peeling should be done with a rapid and constant action. Tiano et al. recommended and used strips about 10 mm × 30 mm in area for stone testing (3 cm2) [5].

However, the literature results indicated that the results are very dependent on the quality of the adhesive layer, the roughness of the tested surface, the flexural stiffness of the tape, and to a minor extent on the attaching pressure and the speed of detachment [6].

There are also differences in the valuation of the amount of peeled off material. Some authors use weighing, while others rely on optical evaluation of the tape area covered by the released material, e.g. the standard ASTM 4214-97 “Standard Test Methods for Evaluating the Degree of Chalking of Exterior Paint Films”.

Drdácký and Slížková observed problems of apparent consolidation effects caused by initial removal of loosened particles on plasters, which does not correspond to the real material cohesion characteristics [7]. They therefore applied a better defined protocol, which is discussed in a later paper for plasters and mortars [8].

Improved techniques used for testing other than bulk materials, e.g. for testing the adhesion of thin films to their substrate, have been suggestedFootnote 5 by other researchers. The method is based on the Scotch Tape test, and improves it in such a way as to obtain a quantitative result. For this, a test strip was proposed which contains several regions with adhesives of different strengths. When performing the Scotch Tape test with this test strip, the adhesive can be identified at which adhesion fails and can then be correlated to the adhesive strength. This approach is hardly applicable for problems of mortar and stone assessment, of course, mainly because the surface roughness is much higher and much more irregular.

Unlike in the field of conservation, in surface coating and in the paint and steel production industries peeling tests have been standardized. For example, in steel production a standardized automated system is available under the trade name CoilScooter®. This system measures the amount of residual dirt on a metal surface. This standardized peeling test is used to check the quality of surfaces, e.g. for steel plates. In the first step, a piece of Scotch® Tape is affixed to the surface, removed and placed on a clean, white sheet of paper. In the second step, the amount of surface residual dirt is evaluated by measuring the reflectivity (grey tone). The dirt pulled off by the tape is an indicator of the quality of the metal surface.

The CoilScooter® automates the sample taking process and measures the reflectivity (grey tone) directly on the production line. The CoilScooter® standardises the Scotch® Tape test by automating the sample taking and measurement process, and it gives reproducible and rather reliable results for the quality of metallic surfaces on the production line, irrespective of the operator. The measurement is based on the reflectivity of the laminated test strip. For this, a special grey-tone sensor was developed. The grey-tone is determined inside the instrument by a green light source and a photodiode.

In principle, this method could be used for inspecting sufficiently smooth cultural heritage surfaces (very fine stone monuments and painted surfaces).

The measurement is based on the ASTM Standard D 3359-08 Standard Test Methods for Measuring Adhesion by Tape Test (or some older variants). This standard is referred to by Daniele et al. [9], who used the tape test for checking the consolidation effect on two types of natural stone—Estoril and Pietra Serena. Unfortunately, they do not describe the testing protocol in detail, and it is difficult to assess the mode and correctness of the application.

The ASTM D 3359-08 method covers procedures for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film. Naturally, it was developed with metal as a substrate and its application for other substrates has not been tested and validated. However, some hints from the test procedure are worth mentioning here.

25 mm wide semitransparent pressure-sensitive tape with an adhesion strength agreed upon by the supplier and the user is needed, (e.g. Permacell 99 tape). Because of the variability in adhesion strength from batch to batch and with time, it is essential that tape from the same batch be used when tests are to be run in different laboratories. If this is not possible, the test method should be used only for ranking a series of test coatings.

The test should be carried out on an area free of blemishes and minor surface imperfections. For tests in the field, ensure that the surface is clean and dry. Extremes of temperature and relative humidity may affect the adhesion of the tape.

On each day of testing, before starting the tests, remove two complete laps of the pressure-sensitive tape from the roll and discard. Remove an additional length at a steady (that is, not jerked) rate, and cut a piece about 75 mm in length.

Place the tape on the surface and smooth it into place with your finger, and then rub firmly with the eraser on the end of a pencil. The colour under the transparent tape is a useful indication of when good contact has been made.

Within 90 ± 30 s of application, remove the tape by seizing the free end and pulling it off rapidly back upon itself (without jerking) at as close to an angle of 180° as possible.

Inspect the tested area.Footnote 6 Repeat the test in two other locations.

In the commentary on this standard it is stated that there is at the present time no test that can precisely assess the actual physical strength of an adhesive bond. Nevertheless, it is possible to obtain an indication of relative adhesion performance.

This standard requires that the free end of the tape be removed rapidly at as close to an angle of 180º as possible. If the peel angle and the rate vary, the force required to remove the tape can change dramatically. Nearly linear increases were observed in peel force approaching 100% as the peel angle was changed from 135° to 180°, and similar large differences in peel force can be expected as the peel rate varies [6]. These effects are related, as they reflect certain rheological properties of the backing and the adhesive that are molecular in origin.

In the field of cultural heritage, the above-mentioned ASTM Standard is replaced by ASTM Standard D 4214-07 Standard Test Methods for Evaluating the Degree of Chalking of Exterior Paint Films, which has been applied and its use has been modified accordingly [10].

This standard suggests four different methods, two of which exploit tape testing. The Transparent Tape Method uses 13-mm-wide pressure sensitive cellulose adhesive tape and a 20 mm eraser wrapped in cellophane tape.

The procedure starts with the application of a 50 mm long piece of 13 mm wide tape to the surface that is being rated. Rub ten times with moderate pressure using the covered eraser, in order to remove all bubbles and prevent scratching. Remove the tape from the surface and adhere it to the sheet by rubbing with the eraser. Label the specimens using a black china marker. All tapes from other measurements are then cut using a razor to a unified size ready for evaluation. Then the tapes with the peeled off particles are evaluated by reflectance measurements, and the results are rated from 0 to 10.

ASTM Standard D 4214-07 refers to a TNO type method, which uses polyethylene transparent tape 13–25 mm in width in the following procedure. Apply a piece of tape 63–100 mm in length to the surface using uniform gentle finger pressure, remove the tape, and lay it with the adhesive side on a piece of dull black velvet (or black paper). Under diffused light, compare the tape on the black velvet with Photographic Reference Standard No. 2 and determine the most closely matching grade.

Although none of the reported standardized methods was developed for testing mortars and stones, their background, knowledge and experience are exploited in a further recommendation for a peeling test for quasi-brittle materials.

The method can be used for making a relative assessment of consolidation effects in individual cases, if an exact methodology and procedure are conserved (see the next paragraph). Examples of such an application are found in the literature, e.g. [8], where the surface consolidation effect was apparently measured on a material with originally very poor cohesion quality. Similarly, useful results on stones were achieved with the peeling test on Carrara Marble weathered samples treated with bio-reinforcing agents inducing new calcite precipitation [5]. A clear reinforcement effect is observed when material removed from treated and untreated weathered marble surfaces is compared (Fig. 1).

Results of peeling tests on weathered and consolidated Carrara Marble [5]

3 Factors influencing peeling test results

The quality of the adhesive layer applied to the tape used for the peeling test is one of the most important parameters influencing the amount of detached material. Some theoretical considerations are widely discussed in a paper by Chiche et al. [6].

They review the fact that in peel tests the applied force necessary for removing a homogeneous adhesive tape from a homogeneous substrate is not constant, and they support the standard approach of removing the impact of force fluctuations in a conventional peel testFootnote 7 by statistical treatment of a quantity of measured data. The same approach, i.e. statistical treatment of results depending on the peeling force and also the cohesion force fluctuations, is also useful in peeling tests on mortars and stones. Thus it is recommended to test the cohesion quality at several tested points over a relatively small area.

The standard approach for the quality of the adhesive layer conserves 90° peel angle experiments with the removal force direction perpendicular to the tested surface. It seems to retain this as a recommended testing parameter. The angle of 180º recommended by some standards may generate higher forces, and may therefore be more effective in cohesion testing, but it is more difficult to keep to it in some practical situations.

The rate effect on the peeling of adhesive tapes from a substrate was also studied in [6]. Two tapes with different adhesives were tested (translucent Scotch 811 3M and transparent Scotch 600 3M). Both exhibited an increase in the force as a function of the peel rate within testing limits from 7 μm/s to 7 mm/s. In real cohesion tests on historic materials, the authors used rates of about 10 mm/s, which seem adequate for the forces that might be necessary for detaching surface layers of degraded mortars or stones.

However, current standard test methods no longer identify a specific tape. Differences in the tapes that are used can lead to different results, as small changes in backing stiffness and adhesive rheology cause large changes in the tension area.

The tape test is also operator sensitive. In the standard design it was made as simple as possible to perform, requiring a minimum of specialized equipment and materials that must meet certain specifications. The accuracy and precision depend largely on the ability of the operator to perform the test in a consistent manner. Key steps that directly reflect the importance of operator skill include the angle and the rate of tape removal.

The flatness of the tested surface has a substantial influence on the peeling force, due to variations in the area to which a tape may adhere. This effect is twofold. Firstly, a larger adhesion area causes a higher probability of touching releasable particles of the surface material. Secondly, the surface of sharp grains protruding from the surface may be so small that the peeling force is not sufficient to peel off individual grains even from rather weak matrices. In some cases, it is not possible to glue a tape to the surface at all. Figure 6 shows such an example—a sandstone surface. Then it is necessary to use tapes with a thick layer of glue, which can better reach the “valleys” between the individual grains. An application of this kind is described in the next example.

4 Experimental studies

4.1 Meaning of peeling testing

Peeling testing is defined as a method for making a quantified assessment of the adhesion of a surface or near-to-surface layer to a substrate. Pressure-sensitive tape is applied to the investigated area and the amount of material detached from the surface after peeling the tape off is measured.

In the conservation field it is assumed that this amount corresponds to the cohesion characteristics of the substrate. Therefore, the peeling test is used for evaluating surface degradation or consolidation effects after strengthening interventions.

4.2 Peeling performance tests on stone specimens

Various series of tests aimed at studying the basic features of stone when peeling off the surface material have been performed and evaluated at ITAM.

The main doubts about the Scotch Tape method lie in the fact that the loosened particles on the tested surface do not represent the cohesion characteristics of the tested material. Therefore, if we repeat the peeling in the same place we will observe a decrease in the released material and thus we see an apparent consolidation effect, which is, however, false. Obviously, we have the same problem when checking consolidation treatment effects on degraded historic materials or on deteriorated materials of any age.

Peeling performance was tested on beams 50 × 50 × 300 mm3 and on cubes 50 × 50 × 50 mm3 of different natural stones, and also on stones after consolidation treatment.

During the tests, the peeling test is repeated several times on the same surface area. In the case under discussion here, it was repeated ten times.

Peeling was studied using AEROTAPE transparent plastic tape 25 mm in width and slightly more than 50 mm in length, i.e. slightly more than the width of the tested specimens. In the second series, an opaque strip 50 mm in width and slightly more than 50 mm in length was used. The tapes were stuck to the surface and smoothed with gentle finger pressure, and were then removed by pulling at an angle of 90°, and weighed on a balance with sensitivity of 0.0001 g. The peeled off material was determined as the difference between the weight of the tape after removal from the surface and the weight of the clean tape before application.

Typical peeling test results for the individual stone specimens are shown in Figs. 2 and 3. The first series of tests was carried out on opuka stone beams, which were in natural state (marked “o”) or had been treated with various consolidants: lime water (vv), “water glass” K2SiO3 (vs) and ethyl silicate (i).

Decrease in material released from the surfaces of natural and consolidated opuka stone samples during sequences of peeling tests carried out repeatedly on the same surface area. There are reported data from two measurements and their average approximation using the procedure described in Sect. 6.4 (Eq. 1)

The results show clearly the influence of repeated peeling on the same surface area, and indicates a source of possible errors when the peeling test is performed without a reasonably standardized procedure.

The second series of tests was performed on cubes of different stones—a fresh opuka, and so-called Maastricht stone. Whilst it was not possible to adhere the narrow tape to the Maastricht stone, and it was therefore not possible to test this material,Footnote 8 the opuka stone gave similar results as in the first case, Fig. 2, here without a well pronounced asymptote characterizing the properties of the natural material.

From the observations above, it follows that this method is quite sensitive to the condition of the surface. However, it does not provide easily interpretable data for reproducible measurements of the material characteristics describing the state of the material below the very near surface layer that is decisive for effective cohesion of an investigated substance.

Moreover, the change in the amounts of released material from a surface that has been repeatedly touched in any manner—by repeated peeling testing, by applying a consolidation treatment, or by cleaning—can make the measurements of consolidation effects non-objective, uncertain and not reproducible.

After repeated peeling, the amount of released material starts to be almost constant, unfortunately for most non-deteriorated building stones very close to the sensitivity of the method or to the error of the measurements (for opuka stone see Figs. 2 and 12).Footnote 9

The surface quality of the stone plays an important role in peeling testing. Typical macro-photographs of the surface of the natural opuka stone are presented in Fig. 4, and of opuka specimens treated with various consolidation agents in Fig. 5.

Both surfaces presented in Fig. 4 enable appropriate adhesion of the testing tapes. However, the rough surface of the beam specimen contained more coarse grains that were not properly attached. This influenced the measured released mass, (see Fig. 2) at the same final quality of the characteristic value after ten steps.

Figure 5 illustrates the physical state of consolidated opuka stone surfaces relevant to the measured released mass values reported in Fig. 2. The presented surface variations do not significantly influence the results of the peeling tests. However, a very uneven surface with sharp peaks and deep valleys, e.g. see Fig. 6, may require very flexible tape with a thick layer of glue for successful measurements, as discussed in Sect. 3.

4.3 Peeling performance tests on artificial stone

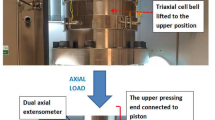

Another series of tests was carried out at ICVBC (Florence) on artificial stone modeled by means of a cementitious mortar.

Specimens imitating stone samples made of cementitious mortars 5 × 5 × 3 cm3 in dimensions were utilized. This material was cured for a long time before the experiments, and the surface was completely carbonated and hydrated. The main mineralogical constituents detected through X-ray diffraction analysis were: quartz, feldspars, calcium silicates, calcium silicate hydrates and calcium silicate aluminate hydrates. The petro-physical characteristics, real and bulk density and total open porosity, determined through helium and mercury pycnometers were 2.64 g/cm3 (±0.01), 1.82 g/cm3 (±0.03) and 31% (±1), respectively. The inert grain size dimension was between 0.06 and 6.40 mm.

The specimens were consolidated with nano-silica, traded as Syton X 30 (Kremer) in an aqueous solution (0.300 g/l of solid particles).

The product was applied with a brush in such a way that the same amounts of solid particles in the solution were introduced. The treatments carried out and the amounts of product applied are reported in Table 1.

Macro-photos of the treated and non-treated samples are shown in Fig. 7. The specimen treated with Syton X 30 shows slight darkening of the surface with a polish effect compared with the untreated specimen.

The peeling test was materialized using a commercial bi-adhesive tape (TESA, binding capacity 1 kg/10 cm). Strips 6 cm in length were cut and weighed on a Gibertini balance (±0.001 g precision), and then one strip was put on the surface of the specimen and softly pressed. With the help of tweezers, the strip was removed (90°) with a rapid and constant action and again weighed. The difference in the weight of the strips corresponds to the amount of superficial material removed. For each specimen, two strips were applied (Fig. 8). The procedure was repeated on the same area of the specimen three times, using new strips, in order to evaluate the cohesion of the surface in the bulk.

Let us further discuss the results of the tests on the artificial stone, as described above and in Table 2, where the data from the peeling test expressed as the amounts of material removed for each single test (single strip) are reported. Figure 9 displays some samples after the peeling test with the respective adhesive strips removed, for each surface.

The reference (non-treated) material displays a decreasing trend in the amount of material removed from first (superficial) test to the third (internal) test, due to higher cohesion of the material in the bulk, as explained above. Three steps are typically not enough for a representative characterization of the cohesion characteristics, though they may sufficiently show the tendency of the change in the material after treatment.

The results show a very good strengthening performance of Syton X 30 (Table 2). The small increase in the amount of material removed in the second peeling test of the samples treated with Syton X 30 (Fig. 9) is due to strong adhesion of the strip to the smooth and compact treated surface, which made it difficult to remove the strip from the surface. However, an increase in the detached material in the second or third peeling test step is observed, as shown in Fig. 2, because the first peeling test application likely breaks and “opens” a thin surface deposit or “crust” layers of different origin, e.g. technological or environmental.

5 Application of peeling tests of surface cohesion in situ

As an example of an in situ application, let us examine the results for the surface cohesion of an opuka stone wall highly degraded by weathering. 20 % polysiloxan treatment (Dynasylan 40) was applied to three selected areas A, B, C (Fig. 10).

Area A is damaged by rather deep local delamination (damage category 2, according to the methodology by Fitzner [11]). Area B is damaged by heavy delamination (damage category 3). Area C exhibits powdering damage, see Fig. 11.

The opuka surface was treated with a 20% solution of siloxane (Dynasylan 40) in ethanol catalyzed by dibuthyltindidodecanate at temperature 15°C and relative humidity 47%. A total amount of 1.2 l/m2 was applied in 3 steps, with breaks lasting 5 min.

The treated surfaces were subjected to peeling tests before and after impregnation. In the case of surfaces A and B, a two-sided pressure-sensitive adhesive tape 40 mm in width was applied. In the case of surface C, a two-sided pressure-sensitive adhesive tape 19 mm in width was applied. For surface C, a thicker gluing layer was used (trade mark Petty), with a load-carrying capacity of 50 kg (Fig. 11). The tested places were different for the untreated and treated areas, but were located very close to each other, e.g. Fig. 11. The results are summarized in Fig. 12, where the raw data is compared with the approximation curves fitted using the evaluation procedure described in Sect. 6.

This example shows that the method is applicable even if there is heavy delamination damage. In this case, the negligible strengthening on surface A seems to be caused by a higher moisture content in the wall in that place, leading to lower absorption of the agent.Footnote 10 The outdoor walls were not protected against possible wetting by driven rain, and the weather conditions during the treatment included day/night temperature fluctuations in the range of 8–24°C. In the other tested places (B and C), positive consolidation effects were measured.

6 A recommendation for the application of peeling testing of the surface cohesion of stone and mortar

6.1 Introduction

The peeling test recommendation covers procedures for assessing the surface cohesion characteristics of mortars and stones by applying and removing pressure sensitive tape over the investigated surface.

Two variants of sampling data during peeling testing are proposed. Method A is primarily intended for use on site, while method B is more suitable for use in the laboratory, where method A is also easily applicable.

The method uses techniques similar to those used for standard methods ASTM D 4214-07 and ASTM D 3359-08, which are intended for other purposes than stone or mortar testing.

6.2 Apparatus and material

Tape. For variant A, a double-coated (double-sided) pressure-sensitive adhesive tape 40 mm in width is needed, while for variant B a single layer pressure-sensitive transparent or semi-transparent tape 25 mm in width is used.

Square ruled paper.

Plastic sampling bag, with a closing pressure zip.

Laboratory balance with sensitivity 0.1 mg.

6.3 Test procedure

Tape preparation. For in situ testing (variant A), the tape samplers are prepared from double-coated pressure-sensitive tape 40 mm in width, as follows:

-

1.

a piece of double-sided pressure-sensitive tape is cut to a length corresponding to the width or length of a square ruled piece of paper,

-

2.

the tape is glued to the square ruled paper,

-

3.

samplers are cut from the tape-paper sheet in dimensions of 10 to 20 mm by 50 mm, in such a way that at one end plain paper 10 mm in width is free from the pressure sensitive tape, see Fig. 13,

-

4.

the sampler is marked, inserted into a plastic sampling bag, and closed,

-

5.

the bag with the sampler is weighed on a laboratory balance with sensitivity 0.1 mg, and the value is recorded in a prepared protocol table,

-

6.

the sampler is ready to be transported to the measurement site.

In variant B, the sampler is cut from a plastic pressure-sensitive tape to a length adequate for the measured surface immediately before the peeling measurement is made. It is recommended to remove and discard two complete laps of tape from the roll before starting the measurements. The measuring length should be removed at a steady rate (i.e., not jerked), and then cut. (This recommendation is also valid for variant A.)

Peeling testing. Select an area without gross defects and imperfections. For tests in situ, ensure that the surface is naturally dry (without liquid water) and that it represents the tested material, e.g. that it is reasonably clean. The measurements may be influenced by extremes in relative humidity and temperature, due to the sensitivity of the plastic tape and the glue layer to these factors.

Place the tape on the measured surface. In variant A, the sampler must be taken out the sampling bag, the cover sheet of the adhesive layer must be removed and kept for readjusting after peeling. In variant B, the plastic strip is simply stuck to the surface.

Smooth the tape into place using a finger (alternatively, a cellophane-coated soft eraser may be used).

After approximately 90 s of application, remove the tape by seizing the free end and pulling it off steadily (without jerking) at a rate of about 10 mm/s and at an angle of 90°.

For in situ variant (A), adjust the protective sheet over the adhesive layer with the released material and insert it back into the sampling bag for transportation, and close the zip. The weight will be measured later, in the laboratory.

For laboratory variant (B) with the plastic strips without protection of the adhesive layer, weigh the strip with the released material on a laboratory balance of sensitivity 0.0001 g.

Repeat the test ten times at the same place.

Repeat the procedure on other places on the investigated surface. The number of tested places depends on the quality of the surface and on its variability over the area. However, three places are typically tested in usual situations.

The sequence of each step taken when measuring an opuka masonry wall in situ is illustrated in Fig. 14.

6.4 Data evaluation

The evaluation of the measured data depends on how the testing is carried out. When only a single measurement was performed in different places, standard statistics should be used (mean value, standard deviation).

When repeated measurements are made in the same place, it is necessary to distinguish two situations. If the released material decreases and approaches a zero value with an increasing number of peelings, use linear regression of the logarithm of the measured data for each measurement place. The regression procedure makes use of an approximation of the common logarithm of the measured released material in mg by a quadratic polynomial, i.e. the data model is created in the form

where n is a sequence of measurements in a given place, and ε is a random parameter with zero mean value.

For purposes of comparison, select a reasonably representative regression smoothed value for characterizing the surface quality, e.g. the value of the third or fourth test repetition. The data from the first two repetitions may be severely biased, due to local mechanical surface damage or similar imperfections.

If repeated measurements are made at the same place, and the response provides decreasing amounts of released material with increasing number of peelings, and the results approach a nonzero value, use nonlinear regression of the measured data for each place where the measurements were made. The form

describing the sequence of weights of the removed material m(n) has been suggested in [10].

7 Conclusions

The peeling test, also known in the literature as the Scotch Tape test, has been used all over the world for assessing the consolidation or strengthening efficiency of various treatments of degraded stone surfaces. In the past, no standard protocols or rules were established for these applications. The method was therefore not reliable, and could produce false results.

This paper has explained the shortcomings of peeling testing, and has reviewed factors which influence the results achieved when it is applied.

We have established reliable procedures and a standard protocol for testing the cohesion characteristics of brittle and quasi-brittle materials, mainly mortars and stones, by means of peeling tests. We have further formulated recommendations for performing peeling tests on historic stone surfaces and for evaluating the results that are obtained.

Notes

Comment: Scratching is not applied in the case of bulk materials, e.g. mortars or stones that have no coating layer.

Definition Copyright ©1989 CRC Press LLC. All rights reserved [1].

SME-targeted Collaborative Research Project “Stone conservation for refurbishment of buildings”, supported from grant No. 213651 under the EC 7th Framework Programme, coordinated by Dr. Gerald Ziegenbalg, IBZ Freiberg, Germany.

Comment: It should be mentioned that ‘Tape Test’ has a well-defined meaning in medicine.

For film adhesion testing, the area is prepared by cross cutting in order to create a grid from the sub-squares of which the film can be pulled off.

ASTM 1999 Standard test method for peel or stripping strength of adhesive bonds, ASTM Standard 903-98.

The Maastricht stone had to be tested using the 50 mm wide tape mentioned above, which gave measurable results.

The authors further tested limestone varieties, various sandstone types, marble and granite.

For the sake of comparison, laminated opuka stone was impregnated in laboratory conditions (temperature 20°C, RH 61%), by means of capillary sorption of the treatment solution. After 1 week, the test specimen had absorbed 9.14% by mass of the 20% Dynasylan 40.

References

http://composite.about.com/library/glossary/s/bldef-s4726.htm

Mora P, Torraca G (1965) Fissativi per dipinti murali. Bollettino Istituto Centrale del Restauro, Rome, pp 109–132

Daniele V, Taglieri G (2010) Nanolime suspensions applied on natural lithotypes: the influence of concentration and residual water content on carbonatation process and on treatment effectiveness. J Cult Herit 11(2010):102–106

Giorgi R, Dei L, Baglioni P (2000) A new method for consolidating wall paintings based on dispersions of lime in alcohol. Stud Conserv 45:154–161

Tiano P et al (2006) Biomediated reinforcement of weathered calcareous stones. J Cult Herit 7:49–55

Chiche A, Zhang W, Stafford CM, Karim A (2005) A new design for high-throughput peel tests: statistical analysis and example. Meas Sci Technol 16:183–190

Drdácký M, Slížková Z (2006) Nondestructive survey of degraded and consolidated renders of the Pernštejn Castle, Report ÚTAM AVČR, ÚTAM AVČR Praha, August 2006

Drdácký M, Slížková Z (2008) Calcium hydroxide based consolidation of lime mortars and stone. In: Delgado-Rodrigues J, Mimoso JM (eds) Proceedings of the international symposium “stone consolidation in cultural heritage”, LNEC, Lisbon, May 2008, pp 299–308. ISBN 978-972-49-2135-8

Daniele V, Taglieri G, Quaresima R (2007) The nano-limes in Cultural Heritage conservation: characterisation and analysis of the carbonation process. J Cult Herit 9:294–301

Ferron A (2007) The consolidation of earthen surface finishes: a study of disaggregating plasters at Mesa Verde National Park. MSc thesis, University of Pennsylvania, p. 144

Fitzner B (2004) Documentation and evaluation of stone damage on monuments. In: Kwiatkowski D, Löfvendahl R (eds) Proceedings of the 10th international congress on deterioration and conservation of stone, ICOMOS Sweden, Stockholm, pp 677–690

Acknowledgments

This paper is based on results and experience acquired with support from Institutional Research Plan AV0Z20710524, from the EC 7th FP funded STONECORE project and from Czech Grant Agency grant No. 103/09/2067.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Drdácký, M., Lesák, J., Rescic, S. et al. Standardization of peeling tests for assessing the cohesion and consolidation characteristics of historic stone surfaces. Mater Struct 45, 505–520 (2012). https://doi.org/10.1617/s11527-011-9778-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-011-9778-x