Carbon Materials Derived from Poly(aniline-co-p-phenylenediamine) Cryogels

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of Cryogels

2.2. Carbonization

2.3. Characterization

3. Results and Discussion

3.1. Thermogravimetric Analysis

3.2. Carbonization Yield

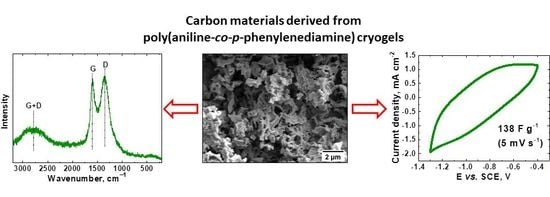

3.3. Raman Spectroscopy

3.4. Morphology

3.5. Specific Surface Area

3.6. Electrochemistry

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Inagaki, M.; Toyoda, M.; Soneda, Y.; Morishita, T. Nitrogen-doped carbon materials. Carbon 2018, 132, 104–140. [Google Scholar] [CrossRef]

- Qu, L.T.; Liu, Y.; Baek, J.B.; Dai, L.M. Nitrogen-doped graphene as efficient metal-free electrocatalyst for oxygen reduction in fuel cells. ACS Nano 2010, 4, 1321–1326. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.J.; Tang, S.; Yin, Y.; Sun, S.H.; Qiao, J.L. Hierarchical porous N-doped graphene foams with superior oxygen reduction reactivity for polymer electrolyte membrane fuel cells. Appl. Energy 2016, 175, 459–467. [Google Scholar] [CrossRef]

- Li, L.; Zhou, G.M.; Yin, L.C.; Koratkar, N.; Li, F.; Cheng, H.M. Stabilizing sulfur cathodes using nitrogen-doped graphene as a chemical immobilizer for Li-S batteries. Carbon 2016, 108, 120–126. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Shao, Y.Y.; Matson, D.W.; Li, J.H.; Lin, Y.H. Nitrogen-doped graphene and its application in electrochemical biosensing. ACS Nano 2010, 4, 1790–1798. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.M.; dos Santos, M.C.; Carvalho, B.R.; Lv, R.T.; Li, Q.; Fujisawa, K.; Elias, A.L.; Lei, Y.; Perea-Lopez, N.; Endo, M.; et al. Ultrasensitive molecular sensor using N-doped graphene through enhanced Raman scattering. Sci. Adv. 2016, 2, e1600322. [Google Scholar] [CrossRef] [Green Version]

- Travlou, N.A.; Bandosz, T.J. N-doped polymeric resin-derived porous carbons as efficient ammonia removal and detection media. Carbon 2017, 117, 228–239. [Google Scholar] [CrossRef]

- Duan, X.G.; Indrawirawan, S.; Sun, H.Q.; Wang, S.B. Effects of nitrogen-, boron-, and phosphorus-doping or codoping on metal-free graphene catalysis. Catal. Today 2015, 249, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Tian, W.J.; Zhang, H.Y.; Sun, H.Q.; Tade, M.O.; Wang, S.B. Template-free synthesis of N-doped carbon with pillared-layered pores as bifunctional materials for supercapacitor and environmental applications. Carbon 2017, 118, 98–105. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Xu, D.; Wang, C.C.; Qian, W.J.; Guo, J.; Yan, F. Ferric citrate-derived N-doped hierarchical porous carbons for oxygen reduction reaction and electrochemical supercapacitors. Carbon 2017, 115, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Jeong, H.M.; Lee, J.W.; Shin, W.H.; Choi, Y.J.; Shin, H.J.; Kang, J.K.; Choi, J.W. Nitrogen-doped graphene for high-performance ultracapacitors and the importance of nitrogen-doped sites at basal planes. Nano Lett. 2011, 11, 2472–2477. [Google Scholar] [CrossRef] [PubMed]

- Bai, F.H.; Xia, Y.D.; Chen, B.L.; Su, H.Q.; Zhu, Y.Q. Preparation and carbon dioxide uptake capacity of N-doped porous carbon materials derived from direct carbonization of zeolitic imidazolate framework. Carbon 2014, 79, 213–226. [Google Scholar] [CrossRef]

- Bashkova, S.; Bagreev, A.; Bandosz, T.J. Adsorption/oxidation of CH3SH on activated carbons containing nitrogen. Langmuir 2003, 19, 6115–6121. [Google Scholar] [CrossRef]

- Mangun, C.L.; Benak, K.R.; Economy, J.; Foster, K.L. Surface chemistry, pore sizes and adsorption properties of activated carbon fibers and precursors treated with ammonia. Carbon 2001, 39, 1809–1820. [Google Scholar] [CrossRef]

- Mangun, C.L.; DeBarr, J.A.; Economy, J. Adsorption of sulfur dioxide on ammonia-treated activated carbon fibers. Carbon 2001, 39, 1689–1696. [Google Scholar] [CrossRef]

- Luo, Z.Q.; Lim, S.H.; Tian, Z.Q.; Shang, J.Z.; Lai, L.F.; MacDonald, B.; Fu, C.; Shen, Z.X.; Yu, T.; Lin, J.Y. Pyridinic N doped graphene: Synthesis, electronic structure, and electrocatalytic property. J. Mater. Chem. 2011, 21, 8038–8044. [Google Scholar] [CrossRef]

- Nakajima, T.; Koh, M. Synthesis of high crystalline carbon-nitrogen layered compounds by CVD using nickel and cobalt catalysts. Carbon 1997, 35, 203–208. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.L.; Zhou, Y.; Zhang, X.; Cai, B.; Qiu, J.S. Flowing nitrogen assisted-arc discharge synthesis of nitrogen-doped single-walled carbon nanohorns. Appl. Surf. Sci. 2013, 277, 88–93. [Google Scholar] [CrossRef]

- Panchakarla, L.S.; Subrahmanyam, K.S.; Saha, S.K.; Govindaraj, A.; Krishnamurthy, H.R.; Waghmare, U.V.; Rao, C.N.R. Synthesis, structure, and properties of boron- and nitrogen-doped graphene. Adv. Mater. 2009, 21, 4726–4730. [Google Scholar] [CrossRef]

- Stejskal, J.; Sapurina, I.; Trchová, M.; Konyushenko, E.N. Oxidation of aniline: Polyaniline granules, nanotubes, and oligoaniline microspheres. Macromolecules 2008, 41, 3530–3536. [Google Scholar] [CrossRef]

- Stejskal, J.; Bober, P.; Trchová, M.; Kovalcik, A.; Hodan, J.; Hromádková, J.; Prokeš, J. Polyaniline cryogels supported with poly(vinyl alcohol): Soft and conducting. Macromolecules 2017, 50, 972–978. [Google Scholar] [CrossRef]

- Mentus, S.; Ćirić-Marjanović, G.; Trchová, M.; Stejskal, J. Conducting carbonized polyaniline nanotubes. Nanotechnology 2009, 20, 245601. [Google Scholar] [CrossRef] [PubMed]

- Trchová, M.; Konyushenko, E.N.; Stejskal, J.; Kovářová, J.; Ćirić-Marjanović, G. The conversion of polyaniline nanotubes to nitrogen-containing carbon nanotubes and their comparison with multi-walled carbon nanotubes. Polym. Degrad. Stab. 2009, 94, 929–938. [Google Scholar] [CrossRef]

- Bober, P.; Pfleger, J.; Pašti, I.A.; Gavrilov, N.; Filippov, S.K.; Klepac, D.; Trchová, M.; Hlídková, H.; Stejskal, J. Carbogels: Carbonized conducting polyaniline/poly(vinyl alcohol) aerogels derived from cryogels for electrochemical capacitors. J. Mater. Chem. A 2019, 7, 1785–1796. [Google Scholar] [CrossRef]

- Prokeš, J.; Stejskal, J.; Křivka, I.; Tobolková, E. Aniline-phenylenediamine copolymers. Synth. Met. 1999, 102, 1205–1206. [Google Scholar] [CrossRef]

- Stejskal, J. Polymers of phenylenediamines. Prog. Polym. Sci. 2015, 41, 1–31. [Google Scholar] [CrossRef]

- Zhu, D.Z.; Cheng, K.; Wang, Y.W.; Sun, D.M.; Gan, L.H.; Chen, T.; Jiang, J.X.; Liu, M.X. Nitrogen-doped porous carbons with nanofiber-like structure derived from poly(aniline-co-p-phenylenediamine) for supercapacitors. Electrochim. Acta 2017, 224, 17–24. [Google Scholar] [CrossRef]

- Xiang, X.X.; Liu, E.H.; Huang, Z.Z.; Shen, H.J.; Tian, Y.Y.; Xiao, C.Y.; Yang, J.J.; Mao, Z.H. Preparation of activated carbon from polyaniline by zinc chloride activation as supercapacitor electrodes. J. Solid State Electrochem. 2011, 15, 2667–2674. [Google Scholar] [CrossRef]

- Plachý, T.; Sedlačík, M.; Pavlínek, V.; Morávková, Z.; Hajná, M.; Stejskal, J. An effect of carbonization on the electrorheology of poly(p-phenylenediamine). Carbon 2013, 63, 187–195. [Google Scholar] [CrossRef]

- Milakin, K.A.; Trchová, M.; Acharya, U.; Hodan, J.; Hromádková, J.; Pfleger, J.; Zasońska, B.A.; Stejskal, J.; Bober, P. Conducting composite cryogels based on poly(aniline-co-p-phenylenediamine) supported by poly(vinyl alcohol). Synth. Met. 2018, 246, 144–149. [Google Scholar] [CrossRef]

- Bober, P.; Gavrilov, N.; Kovalcik, A.; Mičušík, M.; Unterweger, C.; Pašti, I.A.; Šeděnková, I.; Acharya, U.; Pfleger, J.; Filippov, S.K.; et al. Electrochemical properties of lignin/polypyrrole composites and their carbonized analogues. Mater. Chem. Phys. 2018, 213, 352–361. [Google Scholar] [CrossRef]

- Strawhecker, K.E.; Manias, E. Structure and properties of poly(vinyl alcohol)/Na+ montmorillonite nanocomposites. Chem. Mater. 2000, 12, 2943–2949. [Google Scholar] [CrossRef]

- Li, W.G.; Wan, M.X. Stability of polyaniline synthesized by a doping-dedoping-redoping method. J. Appl. Polym. Sci. 1999, 71, 615–621. [Google Scholar] [CrossRef]

- Chan, H.S.O.; Teo, M.Y.B.; Khor, E.; Lim, C.N. Thermal-analysis of conducting polymers. 1. Thermogravimetry of acid-doped polyanilines. J. Therm. Anal. 1989, 35, 765–774. [Google Scholar] [CrossRef]

- Mostafaei, A.; Zolriasatein, A. Synthesis and characterization of conducting polyaniline nanocomposites containing ZnO nanorods. Prog. Nat. Sci. Mater. Int. 2012, 22, 273–280. [Google Scholar] [CrossRef] [Green Version]

- Rozlívková, Z.; Trchová, M.; Exnerová, M.; Stejskal, J. The carbonization of granular polyaniline to produce nitrogen-containing carbon. Synth. Met. 2011, 161, 1122–1129. [Google Scholar] [CrossRef]

- Ćirić-Marjanović, G.; Pašti, I.; Mentus, S. One-dimensional nitrogen-containing carbon nanostructures. Prog. Mater. Sci. 2015, 69, 61–182. [Google Scholar] [CrossRef]

- Shie, J.L.; Chen, Y.H.; Chang, C.Y.; Lin, J.P.; Lee, D.J.; Wu, C.H. Thermal pyrolysis of poly(vinyl alcohol) and its major products. Energy Fuels 2002, 16, 109–118. [Google Scholar] [CrossRef]

- Wang, J.; Polleux, J.; Lim, J.; Dunn, B. Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J. Phys. Chem. C 2007, 111, 14925–14931. [Google Scholar] [CrossRef]

| Aniline Mole Fraction, % | Carbonization Yield, % | ID/IG |

|---|---|---|

| 100 (PANI) | 39 | 2.96 |

| 80 | 45 | 2.88 |

| 70 | 35 | 2.51 |

| 0 (PPDA) | 34 | 2.39 |

| Aniline Mole Fraction, % | Before Carbonization | After Carbonization | ||||

|---|---|---|---|---|---|---|

| Specific Surface Area, m2·g−1 | Pore Volume, cm3·g−1 | Specific Surface Area, m2·g−1 | Pore Volume, cm³·g−1 | Capacitance at 5 mV·s−1, F·g−1 | Capacitance at 100 mV·s−1, F·g−1 | |

| 100 | 18 | 0.016 | 328 | 0.34 | 102 | 7.4 |

| 80 | 75 | 0.020 | 325 | 0.11 | 106 | 24.6 |

| 70 | 78 | 0.012 | 511 | 0.24 | 117 | 21.2 |

| 0 | 0.11 | 0.014 | 931 | 0.42 | 138 | 34.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milakin, K.A.; Gavrilov, N.; Pašti, I.A.; Trchová, M.; Zasońska, B.A.; Stejskal, J.; Bober, P. Carbon Materials Derived from Poly(aniline-co-p-phenylenediamine) Cryogels. Polymers 2020, 12, 11. https://doi.org/10.3390/polym12010011

Milakin KA, Gavrilov N, Pašti IA, Trchová M, Zasońska BA, Stejskal J, Bober P. Carbon Materials Derived from Poly(aniline-co-p-phenylenediamine) Cryogels. Polymers. 2020; 12(1):11. https://doi.org/10.3390/polym12010011

Chicago/Turabian StyleMilakin, Konstantin A., Nemanja Gavrilov, Igor A. Pašti, Miroslava Trchová, Beata A. Zasońska, Jaroslav Stejskal, and Patrycja Bober. 2020. "Carbon Materials Derived from Poly(aniline-co-p-phenylenediamine) Cryogels" Polymers 12, no. 1: 11. https://doi.org/10.3390/polym12010011