Fatigue Crack Initiation Change of Cast AZ91 Magnesium Alloy from Low to Very High Cycle Fatigue Region

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Material

2.2. Experimental Methods

3. Results and Discussion

3.1. Fatigue Tests

3.2. Fatigue Crack Initiation—Surface Analysis

3.3. Fatigue Crack Initiation—FIB Cutting

4. Conclusions

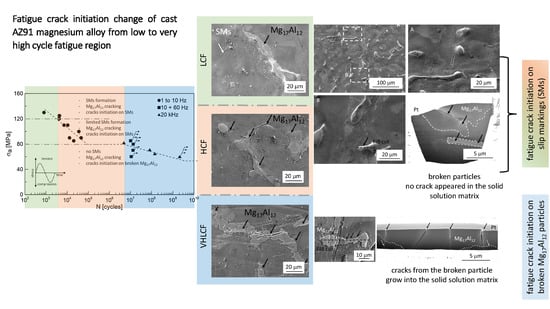

- Low and high (below 107 cycles) cycle fatigue regions were characteristic by the fatigue crack initiation on the SMs created in the solid solution areas of the cast microstructure of AZ91 magnesium alloy. Additionally, broken Mg17Al12 intermetallic particles were observed in the microstructure, however, the cracks almost always stopped on the particle/solid solution interface and did not propagate to the material bulk.

- Fatigue cracks in the very high cycle fatigue region initiated on the broken primary Mg17Al12 intermetallic particles grow towards the solid solution areas.

- The change of the fatigue crack initiation mechanism led to the fatigue limit decrease from the value of 80 MPa determined from low-frequency tests data for 1 × 107 cycles to 60 MPa determined from very high-frequency tests for 2 × 109 cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, M.; Sharon, N.M.L. Magnesium, Magnesium Alloys, and Magnesium Composites; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Altwicker, H.; Bauer, A.; Beck, A.; Bohner, H.; Buchmann, W.; Fiedler, R.; Gossrau, G.; Keinert, O.; Menzen, P.; Moschel, W. Magnesium und Seine Legierungen; Springer: Berlin/Heidelberg, Germany, 1939. [Google Scholar]

- Eisenmeier, G.; Holzwarth, B.; Höppel, H.W.; Mughrabi, H. Cyclic deformation and fatigue behaviour of the magnesium alloy AZ91. Mater. Sci. Eng. A 2001, 319–321, 578–582. [Google Scholar] [CrossRef]

- Friedrich, H.E.; Mordike, B.L. Magnesium Technology: Metallurgy, Design Data, Automotive Applications; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Pan, F.; Yang, M.; Chen, X. A Review on Casting Magnesium Alloys: Modification of Commercial Alloys and Development of New Alloys. J. Mater. Sci. Technol. 2016, 32, 1211–1221. [Google Scholar] [CrossRef]

- Murugan, G.; Raghukandan, K.; Pillai, U.T.S.; Pai, B.C.; Mahadevan, K. High cyclic fatigue characteristics of gravity cast AZ91 magnesium alloy subjected to transverse load. Mater. Des. 2009, 30, 2636–2641. [Google Scholar] [CrossRef]

- Ramalingam, V.V.; Ramasamy, P.; Kovukkal, M.D.; Myilsamy, G. Research and Development in Magnesium Alloys for Industrial and Biomedical Applications: A Review. Met. Mater. Int. 2020, 26, 409–430. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N. Precipitates of γ–Mg17Al12 Phase in AZ91 Alloy. In Magnesium Alloys—Design, Processing and Properties; Czerwinski, F., Ed.; InTech: Rijeka, Croatia, 2011; pp. 95–112. [Google Scholar]

- Majhi, J.; Ganguly, S.; Basu, A.; Mondal, A.K. Improved corrosion response of squeeze-cast AZ91 magnesium alloy with calcium and bismuth additions. J. Alloy. Compd. 2021, 873, 159600. [Google Scholar] [CrossRef]

- Choudhary, L.; Singh Raman, R.K. Magnesium alloys as body implants: Fracture mechanism under dynamic and static loadings in a physiological environment. Acta Biomater. 2012, 8, 916–923. [Google Scholar] [CrossRef]

- Wolf, F.I.; Cittadini, A. Chemistry and biochemistry of magnesium. Mol. Asp. Med. 2003, 24, 3–9. [Google Scholar] [CrossRef]

- Saris, N.-E.L.; Mervaala, E.; Karppanen, H.; Khawaja, J.A.; Lewenstam, A. Magnesium: An update on physiological, clinical and analytical aspects. Clin. Chim. Acta 2000, 294, 1–26. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z.; Smith, C.; Sankar, J. Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater. 2014, 10, 4561–4573. [Google Scholar] [CrossRef] [PubMed]

- Witte, F.; Fischer, J.; Nellesen, J.; Crostack, H.-A.; Kaese, V.; Pisch, A.; Beckmann, F.; Windhagen, H. In vitro and in vivo corrosion measurements of magnesium alloys. Biomaterials 2006, 27, 1013–1018. [Google Scholar] [CrossRef] [PubMed]

- Han, H.-S.; Kim, Y.-Y.; Kim, Y.-C.; Cho, S.-Y.; Cha, P.-R.; Seok, H.-K.; Yang, S.-J. Bone formation within the vicinity of biodegradable magnesium alloy implant in a rat femur model. Met. Mater. Int. 2012, 18, 243–247. [Google Scholar] [CrossRef]

- Ghali, E.; Revie, R.W. Corrosion Resistance of Aluminum and Magnesium Alloys: Understanding, Performance, and Testing; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Fintová, S.; Kunz, L. Fatigue properties of magnesium alloy AZ91 processed by severe plastic deformation. J. Mech. Behav. Biomed. Mater. 2015, 42, 219–228. [Google Scholar] [CrossRef]

- Ebel-Wolf, B.; Walther, F.; Eifler, D. Influence of elevated temperatures on the cyclic deformation behaviour of the magnesium die-cast alloys AZ91D and MRI 230D. Mater. Sci. Eng. A 2008, 486, 634–640. [Google Scholar] [CrossRef]

- Chung, C.W.; Ding, R.G.; Chiu, Y.L.; Gao, W. Effect of ECAP on microstructure and mechanical properties of cast AZ91 magnesium alloy. J. Phys. Conf. Ser. 2010, 241, 012101. [Google Scholar] [CrossRef]

- Čížek, L.; Greger, M.; Pawlica, L.; Dobrzański, L.A.; Tański, T. Study of selected properties of magnesium alloy AZ91 after heat treatment and forming. J. Mater. Process. Technol. 2004, 157–158, 466–471. [Google Scholar] [CrossRef]

- Fintová, S.; Anzelotti, G.; Konečná, R.; Nicoletto, G. Casting Pore Characterization by X-Ray Computed Tomography and Metallography. Arch. Mech. Eng. 2010, 57, 263. [Google Scholar] [CrossRef]

- Kunz, L.; Lukáš, P.; Konečná, R.; Fintová, S. Casting defects and high temperature fatigue life of IN 713LC superalloy. Int. J. Fatigue 2012, 41, 47–51. [Google Scholar] [CrossRef]

- Nicoletto, G.; Konečná, R.; Fintova, S. Characterization of microshrinkage casting defects of Al-Si alloys by X-ray computed tomography and metallography. Int. J. Fatigue 2012, 41, 39–46. [Google Scholar] [CrossRef]

- Wolf, B.; Fleck, C.; Eifler, D. Characterization of the fatigue behaviour of the magnesium alloy AZ91D by means of mechanical hysteresis and temperature measurements. Int. J. Fatigue 2004, 26, 1357–1363. [Google Scholar] [CrossRef]

- Park, S.S.; Park, Y.S.; Kim, N.J. Microstructure and properties of strip cast AZ91 Mg alloy. Met. Mater. Int. 2002, 8, 551. [Google Scholar] [CrossRef]

- Hadzima, B.; Janeček, M.; Suchý, P.; Müller, J.; Wagner, L. Microstructure and Corrosion Properties of Fine-Grained Mg-Based Alloys. Mater. Sci. Forum 2008, 584–586, 994–999. [Google Scholar] [CrossRef]

- Yamashita, A.; Horita, Z.; Langdon, T.G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation. Mater. Sci. Eng. A 2001, 300, 142–147. [Google Scholar] [CrossRef]

- Chen, B.; Lin, D.-L.; Jin, L.; Zeng, X.-Q.; Lu, C. Equal-channel angular pressing of magnesium alloy AZ91 and its effects on microstructure and mechanical properties. Mater. Sci. Eng. A 2008, 483–484, 113–116. [Google Scholar] [CrossRef]

- Suh, J.S.; Suh, B.-C.; Choi, J.O.; Kim, Y.M.; You, B.S. Effect of Extrusion Temperature on Mechanical Properties of AZ91 Alloy in Terms of Microstructure and Texture Development. Met. Mater. Int. 2020, 27, 2696–2705. [Google Scholar] [CrossRef]

- Khoubrou, I.; Nami, B.; Miresmaeili, S.M. Investigation on the Creep Behavior of AZ91 Magnesium Alloy Processed by Severe Plastic Deformation. Met. Mater. Int. 2020, 26, 196–204. [Google Scholar] [CrossRef]

- Periyak Gounder, S. Magnesium alloys: A review of applications. Mater. Tehnol. 2019, 881. [Google Scholar] [CrossRef]

- Dimitrov, D.; Shtarbakov, V. Ultrasonic fatigue test of AZ91 magnesium alloy. Mach. Technol. Mater. 2013, 11, 50–53. [Google Scholar]

- ISO. ISO 6892-1:2016 Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO: Geneva, Swithzerland, 2016; p. 79. [Google Scholar]

- ISO. EN 843-2:2006 Advanced Technical Ceramics-Mechanical Properties of Monolithic Ceramics at Room Temperature-Part 2: Determination of Young’s Modulus, Shear Modulus and Poisson’s Ratio; ISO: Brussels, Belgium, 2006; p. 42. [Google Scholar]

- Bathias, C.; Paris, P.C. Gigacycle Fatigue in Mechanical Practice; Taylor & Francis: Oxfordshire, UK, 2004. [Google Scholar]

- Gu, X.N.; Zhou, W.R.; Zheng, Y.F.; Cheng, Y.; Wei, S.C.; Zhong, S.P.; Xi, T.F.; Chen, L.J. Corrosion fatigue behaviors of two biomedical Mg alloys—AZ91D and WE43—In simulated body fluid. Acta Biomater. 2010, 6, 4605–4613. [Google Scholar] [CrossRef] [PubMed]

- Fintová, S.; Kuběna, I.; Chlupová, A.; Jambor, M.; Šulák, I.; Chlup, Z.; Polák, J. Frequency-dependent fatigue damage in polycrystalline copper analyzed by FIB tomography. Acta Mater. 2021, 211, 116859. [Google Scholar] [CrossRef]

- Polák, J. Cyclic Plasticity and Low Cycle Fatigue Life of Metals; Elsevier: Amsterdam, The Netherlands, 1991. [Google Scholar]

- Stanzl-Tschegg, S.E. Influence of material properties and testing frequency on VHCF and HCF lives of polycrystalline copper. Int. J. Fatigue 2017, 105, 86–96. [Google Scholar] [CrossRef]

| Elements | Al | Zn | Mn | Si | Fe | Be | Ni | Cu | Mg |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 8.7 | 0.65 | 0.25 | 0.006 | 0.003 | 0.0008 | 0.0006 | 0.0005 | balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fintová, S.; Trško, L.; Chlup, Z.; Pastorek, F.; Kajánek, D.; Kunz, L. Fatigue Crack Initiation Change of Cast AZ91 Magnesium Alloy from Low to Very High Cycle Fatigue Region. Materials 2021, 14, 6245. https://doi.org/10.3390/ma14216245

Fintová S, Trško L, Chlup Z, Pastorek F, Kajánek D, Kunz L. Fatigue Crack Initiation Change of Cast AZ91 Magnesium Alloy from Low to Very High Cycle Fatigue Region. Materials. 2021; 14(21):6245. https://doi.org/10.3390/ma14216245

Chicago/Turabian StyleFintová, Stanislava, Libor Trško, Zdeněk Chlup, Filip Pastorek, Daniel Kajánek, and Ludvík Kunz. 2021. "Fatigue Crack Initiation Change of Cast AZ91 Magnesium Alloy from Low to Very High Cycle Fatigue Region" Materials 14, no. 21: 6245. https://doi.org/10.3390/ma14216245