Abstract

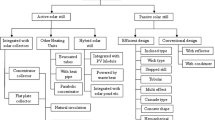

Solar still, which uses solar renewable energy sources, especially solar energy, to produce pure water, is a promising technology as it is abundantly available and eco-friendly. Researchers have innovated in internal and external designs to enhance distillate productivity in solar desalination systems. The present review paper discusses the major internal modifications done in history and recent past to enhance the distillate output. Six sub-sections have been developed concerning historic internal modifications that discuss types of basin liners, water depth, stones, dyes, phase change materials, and weirs. It has been found that among all the historic internal modifications, phase change materials were the most effective with distillate yield enhancement of up to 80%. The limitation in distillate yield made the researchers to perform further modifications to enhance the productivity, and hence, recent internal designs have also been discussed. Recent internal modifications have six sub-sections: fins, wicks, nanofluids, nanostructures, dynamic modifications, and natural materials. Among the recent, dynamic modifications were the most efficient with productivity enhancement of up to 300%, with a maximum cumulative yield of 8.78 kg/m2/day for the rotating wick solar still compared to CSS which gave only 2.21 kg/m2/day. Such a kind of review work has not been performed till date, which covers all the internal design modifications in one paper exhaustively. Furthermore, gaps have been identified, and future perspectives have been presented in the conclusion section. It has been observed that nanostructures, nanoparticles, and dynamic modifications are the most promising internal modifications in recent times that can boost distillate productivity to a greater degree.

Similar content being viewed by others

Availability of data and materials

No data sets are present in this article.

Abbreviations

- AAM:

-

Anodic aluminum oxide membrane

- BGG:

-

Black granite gravel

- CNTs:

-

Carbon nanotubes

- CSES:

-

Contactless solar evaporation structure

- CSS:

-

Conventional solar still

- DSSS:

-

Double slope solar still

- FSS:

-

Fan solar still

- IASS:

-

Inverted absorber solar still

- K:

-

Thermal conductivity

- LHTESS:

-

Latent heat thermal energy storage system

- MDSSS:

-

Modified double-slope solar still

- NIR:

-

Near-infrared

- NPs:

-

Nanoparticles

- PCM:

-

Phase change material

- PDMS:

-

Polydimethylsiloxane

- SS:

-

Solar still

- SSSS:

-

Single slope solar still

- PVD:

-

Physical vapor deposition

- SEM:

-

Scanning electron microscope

- WTSS:

-

Wick-type solar still

- Wt%:

-

Weight percentage

- WTCSS:

-

Weir-type cascade solar still

- Al:

-

Aluminum

- Ag:

-

Silver

- Au:

-

Gold

- Al2O3 :

-

Aluminum oxide

- CuO:

-

Cupric oxide

- Cu2O:

-

Cuprous oxide

- CuSO4·5H2O:

-

Copper sulfate pentahydrate

- Fe2O3 :

-

Iron oxide

- GO:

-

Graphene

- MnO2 :

-

Manganese dioxide

- (NH4)2HPO4 :

-

Diammonium hydrogen phosphate

- PdCl2 :

-

Palladium dichloride

- SnO2 :

-

Tin oxide

- TiO2 :

-

Titanium dioxide

- ZnO:

-

Zinc oxide

References

Abdallah S, Abu-Khader MM, Badran O (2009) Effect of various absorbing materials on the thermal performance of solar stills. Desalination 242:128–137. https://doi.org/10.1016/j.desal.2008.03.036

Abdullah AS, Alarjani A, Abou Al-sood MM et al (2019a) Rotating-wick solar still with mended evaporation technics: experimental approach. Alexandria Eng J 58:1449–1459. https://doi.org/10.1016/j.aej.2019.11.018

Abdullah AS, Essa FA, Omara ZM et al (2019b) Rotating-drum solar still with enhanced evaporation and condensation techniques: comprehensive study. Energy Convers Manag 199:112024. https://doi.org/10.1016/j.enconman.2019.112024

Aghaei Zoori H, Farshchi Tabrizi F, Sarhaddi F, Heshmatnezhad F (2013) Comparison between energy and exergy efficiencies in a weir type cascade solar still. Desalination 325:113–121. https://doi.org/10.1016/j.desal.2013.07.004

Agrawal A, Rana RS (2019) Theoretical and experimental performance evaluation of single-slope single-basin solar still with multiple V-shaped floating wicks. Heliyon 5:e01525. https://doi.org/10.1016/j.heliyon.2019.e01525

Ahsan A, Imteaz M, Thomas UA et al (2014) Parameters affecting the performance of a low cost solar still. Appl Energy 114:924–930. https://doi.org/10.1016/j.apenergy.2013.08.066

Akash B, Osta O, Elayan Y (1998) Experimental Evaluation of a Single-Basin Solar Still Using Different Absorbing Materials 14:307–310

Al-Hamadani AAF, Shukla SK (2012) Water distillation using solar energy system with lauric acid as storage medium. Int J Energy Eng 1:1–8. https://doi.org/10.5923/j.ijee.20110101.01

Al-Hinai H, Al-Nassri M, Jubran BA (2002) Effect of climatic, design and operational parameters on the yield of a simple solar still. Energy Convers Manag 43:1639–1650

Ankoliya DB, Modi KV (2016) Effect of nanofluid in single slope double basin solar still. Int Adv Res Innov Ideas Educ 2:1051–1057

Ansari O, Asbik M, Bah A et al (2013) Desalination of the brackish water using a passive solar still with a heat energy storage system. Desalination 324:10–20. https://doi.org/10.1016/j.desal.2013.05.017

Arani RP, Attia MEH, Al-Kouz W, et al (2021) Energy and exergy efficiency analysis of solar still incorporated with copper plate and phosphate pellets as energy storage material (Environmental Science and Pollution Research, (2021), 28, 35, (48628–48636), https://doi.org/10.1007/s11356-021-14080-5). Environ Sci Pollut Res 28:48637. https://doi.org/10.1007/s11356-021-14359-7

Arjunan TV, Aybar HS, Sadagopan P et al (2014) The effect of energy storage materials on the performance of a simple solar still. Energy Sources, Part A Recover Util Environ Eff 36:131–141. https://doi.org/10.1080/15567036.2010.493924

Arunkumar T, Denkenberger D, Ahsan A, Jayaprakash R (2013) The augmentation of distillate yield by using concentrator coupled solar still with phase change material. Desalination 314:189–192. https://doi.org/10.1016/j.desal.2013.01.018

Arunkumar T, Raj K, Denkenberger D, Velraj R (2018) Heat carrier nanofluids in solar still – a review. Desalin Water Treat 130:1–16. https://doi.org/10.5004/dwt.2018.22972

Attia MEH, Driss Z, Kabeel AE et al (2021a) Phosphate bags as energy storage materials for enhancement of solar still performance. Environ Sci Pollut Res 28:21540–21552. https://doi.org/10.1007/s11356-020-12018-x

Attia MEH, Driss Z, Kabeel AE et al (2021b) Phosphate bed as energy storage materials for augmentation of conventional solar still productivity. Environ Prog Sustain Energy 40:1–9. https://doi.org/10.1002/ep.13581

Attia MEH, Driss Z, Manokar AM, Sathyamurthy R (2020) Effect of aluminum balls on the productivity of solar distillate. J Energy Storage 30:101466. https://doi.org/10.1016/j.est.2020.101466

Ayoub GM, Al-Hindi M, Malaeb L (2015) A solar still desalination system with enhanced productivity. Desalin Water Treat 53:3179–3186. https://doi.org/10.1080/19443994.2014.933040

Bait O, Si-Ameur M (2018) Enhanced heat and mass transfer in solar stills using nanofluids: a review. Sol Energy 170:694–722. https://doi.org/10.1016/j.solener.2018.06.020

Balachandran GB, David PW, Chellam PV et al (2020a) Rehash of cooked oil for the palatable water production using single slope solar still. Fuel 271:117613. https://doi.org/10.1016/j.fuel.2020.117613

Balachandran GB, David PW, Mariappan RK et al (2020b) Improvising the efficiency of single-sloped solar still using thermally conductive nano-ferric oxide. Environ Sci Pollut Res 27:32191–32204. https://doi.org/10.1007/s11356-019-06661-2

Balachandran GB, David PW, Rajendran G et al (2021) Investigation of performance enhancement of solar still incorporated with Gallus gallus domesticus cascara as sensible heat storage material. Environ Sci Pollut Res 28:611–624. https://doi.org/10.1007/s11356-020-10470-3

Bhargva M, Yadav A (2021) Factors affecting the performance of a solar still and productivity enhancement methods: a review. Environ Sci Pollut Res 28:54383–54402. https://doi.org/10.1007/s11356-021-15983-z

Bilal A, Jamil B, Haque NU, Ansari MA (2019) Investigating the effect of pumice stones sensible heat storage on the performance of a solar still. Groundw Sustain Dev 9.https://doi.org/10.1016/j.gsd.2019.100228

Cabeza LF, Mehling H, Hiebler S, Ziegler F (2002) Heat transfer enhancement in water when used as PCM in thermal energy storage. Appl Therm Eng 22:1141–1151. https://doi.org/10.1016/S1359-4311(02)00035-2

Carpay FM., Livingston JD (1973) Controlled nucleation for the regulation of the particle size in monodisperse gold suspensions

Cooper PI, Read WRW (1974) Design philosophy and operating experience for Australian solar stills. Sol Energy 16:1–8. https://doi.org/10.1016/0038-092X(74)90037-1

Cooper TA, Zandavi SH, Ni GW et al (2018) Contactless steam generation and superheating under one sun illumination. Nat Commun 9:1–10. https://doi.org/10.1038/s41467-018-07494-2

Dashtban M, Tabrizi FF (2011) Thermal analysis of a weir-type cascade solar still integrated with PCM storage. Desalination 279:415–422. https://doi.org/10.1016/j.desal.2011.06.044

Dev R, Abdul-Wahab SA, Tiwari GN (2011) Performance study of the inverted absorber solar still with water depth and total dissolved solid. Appl Energy 88:252–264. https://doi.org/10.1016/j.apenergy.2010.08.001

Dubey M, Mishra DR (2021) Experimental analysis of double slope solar still augmented with dye, pebbles and metal chips. Environ Sci Pollut Res 28:22077–22090. https://doi.org/10.1007/s11356-020-11869-8

Ehab BH, Borgford C, Khanafer K (2016) Applications of porous materials and nanoparticles in improving solar desalination systems. J Porous Media 19:993–999. https://doi.org/10.1615/jpormedia.v19.i11.50

El-Dessouky HT, Ettouney HM (2022) Fundamentals of salt water desalination

El-Sebaii AA, Al-Ghamdi AA, Al-Hazmi FS, Faidah AS (2009) Thermal performance of a single basin solar still with PCM as a storage medium. Appl Energy 86:1187–1195. https://doi.org/10.1016/j.apenergy.2008.10.014

El-Sebaii AA, El-Naggar M (2017) Year round performance and cost analysis of a finned single basin solar still. Appl Therm Eng 110:787–794. https://doi.org/10.1016/j.applthermaleng.2016.08.215

El-Sebaii AA, Ramadan MRI, Aboul-Enein S, El-Naggar M (2015) Effect of fin configuration parameters on single basin solar still performance. Desalination 365:15–24. https://doi.org/10.1016/j.desal.2015.02.002

Elango T, Kannan A, Kalidasa Murugavel K (2015) Performance study on single basin single slope solar still with different water nanofluids. Desalination 360:45–51. https://doi.org/10.1016/j.desal.2015.01.004

Eltawil MA, Zhengming Z (2009) Wind turbine-inclined still collector integration with solar still for brackish water desalination. Desalination 249:490–497. https://doi.org/10.1016/j.desal.2008.06.029

Fan L, Khodadadi JM (2011) Thermal conductivity enhancement ofphase change materials for thermal energy storage: a review. Energies 12:24–46. https://doi.org/10.3390/en12010075

Fan P, Wu H, Zhong M et al (2016) Large-scale cauliflower-shaped hierarchical copper nanostructures for efficient photothermal conversion. Nanoscale 8:14617–14624. https://doi.org/10.1039/c6nr03662g

Fukai J, Hamada Y, Morozumi Y, Miyatake O (2002) Effect of carbon-fiber brushes on conductive heat transfer in phase change materials. Int J Heat Mass Transf 45:4781–4792. https://doi.org/10.1016/S0017-9310(02)00179-5

Fukai J, Kanou M, Kodama Y, Miyatake O (2000) Thermal conductivity enhancement of energy storage media using carbon fibers. Energy Convers Manag 41:1543–1556. https://doi.org/10.1016/S0196-8904(99)00166-1

Gugulothu R, Somanchi NS (2015) A review on solar water distillation using sensible and latent heat. 11:354–360.https://doi.org/10.1016/j.proeps.2015.06.072

Gupta B, Kumar A, Baredar PV (2017) Experimental investigation on modified solar still using nanoparticles and water sprinkler attachment. Front Mater 4:1–7. https://doi.org/10.3389/fmats.2017.00023

Hansen RS, Narayanan CS, Murugavel KK (2015) Performance analysis on inclined solar still with different new wick materials and wire mesh. Desalination 358:1–8. https://doi.org/10.1016/j.desal.2014.12.006

Hua Z, Li B, Li L et al (2017) Designing a novel photothermal material of hierarchical microstructured copper phosphate for solar evaporation enhancement. J Phys Chem C 121:60–69. https://doi.org/10.1021/acs.jpcc.6b08975

Jani HK, Modi KV (2019) Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol Energy 179:186–194. https://doi.org/10.1016/j.solener.2018.12.054

Johnson A, Mu L, Park YH, et al (2019) A thermal model for predicting the performance of a solar still with Fresnel lens

Kabeel AE (2009) Performance of solar still with a concave wick evaporation surface. Energy 34:1504–1509. https://doi.org/10.1016/j.energy.2009.06.050

Kabeel AE, Abdelgaied M (2016) Improving the performance of solar still by using PCM as a thermal storage medium under Egyptian conditions. Desalination 383:22–28. https://doi.org/10.1016/j.desal.2016.01.006

Kabeel AE, El-Agouz ES, Athikesavan MM et al (2020) Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: an experimental approach. Environ Sci Pollut Res 27:32218–32228. https://doi.org/10.1007/s11356-019-07288-z

Kabeel AE, Hamed MH, Omara ZM (2012) Augmentation of the basin type solar still using photovoltaic powered turbulence system. Desalin Water Treat 48:182–190. https://doi.org/10.1080/19443994.2012.698811

Kabeel AE, Omara ZM, Essa FA (2014) Improving the performance of solar still by using nanofluids and providing vacuum. Energy Convers Manag 86:268–274. https://doi.org/10.1016/j.enconman.2014.05.050

Kabeel AE, Manokar AM, Sathyamurthy R, et al (2019a) A review on different design modifications employed in inclined solar still for enhancing the productivity. J Sol Energy Eng Trans ASME 141.https://doi.org/10.1115/1.4041547

Kabeel AE, Omara ZM, Essa FA et al (2017) Augmentation of a solar still distillate yield via absorber plate coated with black nanoparticles. Alexandria Eng J 56:433–438. https://doi.org/10.1016/j.aej.2017.08.014

Kabeel AE, Sathyamurthy R, Sharshir SW et al (2019b) Effect of water depth on a novel absorber plate of pyramid solar still coated with TiO2 nano black paint. J Clean Prod 213:185–191. https://doi.org/10.1016/j.jclepro.2018.12.185

Kalidasa Murugavel K, Chockalingam KKSK, Srithar K (2008) Progresses in improving the effectiveness of the single basin passive solar still. Desalination 220:677–686. https://doi.org/10.1016/j.desal.2007.01.062

Kalidasa Murugavel K, Srithar K (2011) Performance study on basin type double slope solar still with different wick materials and minimum mass of water. Renew Energy 36:612–620. https://doi.org/10.1016/j.renene.2010.08.009

Kantesh DC (2012) Design of solar still using phase changing material as a storage medium. Int J Sci Eng Res 3:1–6

Khateeb SA, Farid MM, Selman JR, Al-Hallaj S (2004) Design and simulation of a lithium-ion battery with a phase change material thermal management system for an electric scooter. J Power Sources 128:292–307. https://doi.org/10.1016/j.jpowsour.2003.09.070

Kianifar A, Zeinali Heris S, Mahian O (2012) Exergy and economic analysis of a pyramid-shaped solar water purification system: active and passive cases. Energy 38:31–36. https://doi.org/10.1016/j.energy.2011.12.046

Kumar A, Rai AK, Garg R (2015) Experimental investigation of a passive solar still with paraffin wax as latent heat storage. Proc - Int Conf Technol Sustain Dev ICTSD 2015:1–6. https://doi.org/10.1109/ICTSD.2015.7095891

Kumar HA, Venkateswaran H, Kabeel AE et al (2021) Recent advancements, technologies, and developments in inclined solar still—a comprehensive review. Environ Sci Pollut Res 28:35346–35375. https://doi.org/10.1007/s11356-021-13714-y

Lawrence SA, Gupta SP, Tiwari GN (1990) Effect of heat capacity on the performance of solar still with water flow over the glass cover. Energy Convers Manag 30:277–285. https://doi.org/10.1016/0196-8904(90)90010-V

Liu Y, Chen J, Guo D et al (2015) Floatable, self-cleaning, and carbon-black-based superhydrophobic gauze for the solar evaporation enhancement at the air-water interface. ACS Appl Mater Interfaces 7:13645–13652. https://doi.org/10.1021/acsami.5b03435

Liu KK, Jiang Q, Tadepalli S et al (2017) Wood-graphene oxide composite for highly efficient solar steam generation and desalination. ACS Appl Mater Interfaces 9:7675–7681. https://doi.org/10.1021/acsami.7b01307

Mahdi JT, Smith BE, Sharif AO (2011) An experimental wick-type solar still system: design and construction. Desalination 267:233–238. https://doi.org/10.1016/j.desal.2010.09.032

Mahian O, Kianifar A (2011) Mathematical modelling and experimental study of a solar distillation system. Proc Inst Mech Eng Part C J Mech Eng Sci 225:1203–1212. https://doi.org/10.1177/2041298310392648

Manikandan V, Shanmugasundaram K, Shanmugan S et al (2013) Wick type solar stills: a review. Renew Sustain Energy Rev 20:322–335. https://doi.org/10.1016/j.rser.2012.11.046

Manokar AM, Taamneh Y, Kabeel AE et al (2018a) Review of different methods employed in pyramidal solar still desalination to augment the yield of freshwater. Desalin Water Treat 136:20–30. https://doi.org/10.5004/dwt.2018.23188

Manokar AM, Vimala M, Winston DP et al (2019) Different parameters affecting the condensation rate on an active solar still—a review. Environ Prog Sustain Energy 38:286–296. https://doi.org/10.1002/ep.12923

Manokar AM, Winston DP (2017) Experimental analysis of single basin single slope finned acrylic solar still. Mater Today Proc 4:7234–7239. https://doi.org/10.1016/j.matpr.2017.07.051

Manokar AM, Winston DP, Kabeel AE et al (2018b) Different parameter and technique affecting the rate of evaporation on active solar still -a review. Heat Mass Transf Und Stoffuebertragung 54:593–630. https://doi.org/10.1007/s00231-017-2170-9

Martin CL, Goswami DY (2005) Solar Energy Pocket Reference

Mevada D, Panchal H, Sadasivuni K, kumar, et al (2020) Effect of fin configuration parameters on performance of solar still: a review. Groundw Sustain Dev 10:100289. https://doi.org/10.1016/j.gsd.2019.100289

Mohiuddin SA, Kaviti AK, Srinivasa Rao T (2021) Nanostructures as high absorption energy materials---a review. In: Jha K, Gulati P, Tripathi UK (eds) Recent advances in sustainable technologies. Springer Singapore, Singapore, pp 315–323

Murugavel KK, Sivakumar S, Ahamed JR et al (2010) Single basin double slope solar still with minimum basin depth and energy storing materials. Appl Energy 87:514–523. https://doi.org/10.1016/j.apenergy.2009.07.023

Muthu Manokar A, Kalidasa Murugavel K, Esakkimuthu G (2014) Different parameters affecting the rate of evaporation and condensation on passive solar still - a review. Renew Sustain Energy Rev 38:309–322. https://doi.org/10.1016/j.rser.2014.05.092

Muthu Manokar A, Prince Winston D (2017) Comparative study of finned acrylic solar still and galvanised iron solar still. Mater Today Proc 4:8323–8327. https://doi.org/10.1016/j.matpr.2017.07.175

Muthu Manokar A, Prince Winston D, Kabeel AE et al (2018) Integrated PV/T solar still- a mini-review. Desalination 435:259–267. https://doi.org/10.1016/j.desal.2017.04.022

Nafey AS, Abdelkader M, Abdelmotalip A, Mabrouk AA (2001) Solar still productivity enhancement. Energy Convers Manag. https://doi.org/10.1016/S0196-8904(00)00107-2

Naim MM, Abd El Kawi MA (2003) Non-conventional solar stills. Part 1. Non-conventional solar stills with charcoal particles as absorber medium. Desalination 153:55–64. https://doi.org/10.1016/S0011-9164(02)01093-7

Natarajan SK, Suraparaju SK, Elavarasan RM, et al (2022) An experimental study on eco-friendly and cost-effective natural materials for productivity enhancemento single slope solar still. Environ Sci Pollut Res 29:1917–1936. https://doi.org/10.1007/s11356-021-15764-8

Nijmeh S, Odeh S, Akash B (2005) Experimental and theoretical study of a single-basin solar sill in Jordan. Int Commun Heat Mass Transf 32:565–572. https://doi.org/10.1016/j.icheatmasstransfer.2004.06.006

Omara AAM, Mohammed HA (2019) Phase change materials (PCMs) for improving solar still productivity : a review. Springer International Publishing

Omara ZM, Abdullah AS, Dakrory T (2017) Improving the productivity of solar still by using water fan and wind turbine. Sol Energy 147:181–188. https://doi.org/10.1016/j.solener.2017.03.041

Pal P, Yadav P, Dev R, Singh D (2017) Performance analysis of modified basin type double slope multi–wick solar still. Desalination 422:68–82. https://doi.org/10.1016/j.desal.2017.08.009

Panchal HN (2015) Performance analysis of solar still with cow dung cakes and blue metal stones. Front Energy 9:180–186. https://doi.org/10.1007/s11708-015-0361-y

Pansal K, Ramani B, Sadasivuni K, kumar, et al (2020) Use of solar photovoltaic with active solar still to improve distillate output: a review. Groundw Sustain Dev 10:100341. https://doi.org/10.1016/j.gsd.2020.100341

Phadatare MK, Verma SK (2007) Influence of water depth on internal heat and mass transfer in a plastic solar still. Desalination 217:267–275. https://doi.org/10.1016/j.desal.2007.03.006

Priya SS, Mahadi UI (2013) Effect of different absorbing materials on solar Manipal. Ijaiem 2:301–304

Py X, Olives R, Mauran S (2001) Paraffin/porous-graphite-matrix composite as a high and constant power thermal storage material. Int J Heat Mass Transf 44:2727–2737. https://doi.org/10.1016/S0017-9310(00)00309-4

Rafeek MTM, Muthu V, Athikesavan MM et al (2022) Experimental investigation of an active inclined solar panel absorber solar still—energy and exergy analysis. Environ Sci Pollut Res 29:14005–14018. https://doi.org/10.1007/s11356-021-16444-3

Rahbar N, Esfahani JA (2012) Experimental study of a novel portable solar still by utilizing the heatpipe and thermoelectric module. Desalination 284:55–61. https://doi.org/10.1016/j.desal.2011.08.036

Rai SN, Dutt DK, andTiwari G. (1994) Some experimental and theoretical studies of a single basin solar still. Renew Energy 4:401–407. https://doi.org/10.1016/0960-1481(94)90047-7

Rajaseenivasan T, Elango T, Kalidasa Murugavel K (2013) Comparative study of double basin and single basin solar stills. Desalination 309:27–31. https://doi.org/10.1016/j.desal.2012.09.014

Rajaseenivasan T, Prakash R, Vijayakumar K, Srithar K (2017) Mathematical and experimental investigation on the influence of basin height variation and stirring of water by solar PV panels in solar still. Desalination 415:67–75. https://doi.org/10.1016/j.desal.2017.04.010

Rajaseenivasan T, Srithar K (2016) Performance investigation on solar still with circular and square fins in basin with CO2 mitigation and economic analysis. Desalination 380:66–74. https://doi.org/10.1016/j.desal.2015.11.025

Rajvanshi AK (1981) Effect of various dyes on solar distillation. Sol Energy 27:51–65. https://doi.org/10.1016/0038-092X(81)90020-7

Sadineni SB, Hurt R, Halford CK, Boehm RF (2008) Theory and experimental investigation of a weir-type inclined solar still. Energy 33:71–80. https://doi.org/10.1016/j.energy.2007.08.003

Sakthivel M, Shanmugasundaram S (2008) Effect of energy storage medium (black granite gravel) on the performance of a solar still. Int J Energy Res 32:68–82. https://doi.org/10.1002/er.1335

Sarhaddi F, Farshchi Tabrizi F, Aghaei Zoori H, Mousavi SAHS (2017) Comparative study of two weir type cascade solar stills with and without PCM storage using energy and exergy analysis. Energy Convers Manag 133:97–109. https://doi.org/10.1016/j.enconman.2016.11.044

Shanmugan S (2013) Experimental investigation of various energy absorbing materials on performance of single slope single basin solar still with hot water provision. Int J Innov Res Sci Eng Technol 2013:7760–7767

Sharshir SW, Yang N, Peng G, Kabeel AE (2016) Factors affecting solar stills productivity and improvement techniques: a detailed review. Appl Therm Eng J 100:267–284

Shukla A, Kant K, Sharma A (2017) Solar Still with Latent Heat Energy Storage: a Review 41:34–46

Sodha MS, Kumar A, Tiwari GN, Pandey GC (1980) Effects of dye on the performance of a solar still. Appl Energy 7:147–162. https://doi.org/10.1016/0306-2619(80)90055-0

Sodha MS, Kumar A, Tiwari GN, Tyagi RC (1981) Simple multiple wick solar still: analysis and performance. Sol Energy 26:127–131. https://doi.org/10.1016/0038-092X(81)90075-X

Suneja S, Tiwari GN, Rai SN (1997) Parametric study of an inverted absorber double-effect solar distillation system. Desalination 109:177–186. https://doi.org/10.1016/S0011-9164(97)00063-5

Suraparaju SK, Natarajan SK (2021) Experimental investigation of single-basin solar still using solid staggered fins inserted in paraffin wax PCM bed for enhancing productivity. Environ Sci Pollut Res 28:20330–20343. https://doi.org/10.1007/s11356-020-11980-w

Tabrizi FF, Dashtban M, Moghaddam H (2010a) Experimental investigation of a weir-type cascade solar still with built-in latent heat thermal energy storage system. Desalination 260:248–253. https://doi.org/10.1016/j.desal.2010.03.033

Tabrizi FF, Dashtban M, Moghaddam H, Razzaghi K (2010b) Effect of water flow rate on internal heat and mass transfer and daily productivity of a weir-type cascade solar still. Desalination 260:239–247. https://doi.org/10.1016/j.desal.2010.03.037

Thakur AK, Agarwal D, Khandelwal P, Dev S (2018) Comparative study and yield productivity of nano-paint and nano-fluid used in a passive-type single basin solar still. Lect Notes Electr Eng 435:709–716. https://doi.org/10.1007/978-981-10-4286-7_70

Thakur AK, Sathyamurthy R (2022) Improving the potable water generation through tubular solar still using eggshell powder (bio-based energy source) as a natural energy storage material — an experimental approach. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-18906-8

Thakur AK, Sathyamurthy R, Ganesh Kumar P (2022a) A comparative investigation of energy storage potential of nanoparticles doped in black paint coated absorber for solar desalination application. Springer Singapore

Thakur AK, Sathyamurthy R, Saidur R et al (2022b) Exploring the potential of MXene-based advanced solar-absorber in improving the performance and efficiency of a solar-desalination unit for brackish water purification. Desalination 526:115521. https://doi.org/10.1016/j.desal.2021.115521

Thakur AK, Sathyamurthy R, Sharshir SW et al (2021a) A novel reduced graphene oxide based absorber for augmenting the water yield and thermal performance of solar desalination unit. Mater Lett 286:128867. https://doi.org/10.1016/j.matlet.2020.128867

Thakur AK, Sathyamurthy R, Sharshir SW et al (2021b) Performance analysis of a modified solar still using reduced graphene oxide coated absorber plate with activated carbon pellet. Sustain Energy Technol Assessments 45:101046. https://doi.org/10.1016/j.seta.2021.101046

Thakur AK, Sathyamurthy R, Sharshir SW et al (2021c) An experimental investigation of a water desalination unit using different microparticle-coated absorber plate: yield, thermal, economic, and environmental assessments. Environ Sci Pollut Res 28:37371–37386. https://doi.org/10.1007/s11356-021-12837-6

Thakur AK, Sharshir SW, Ma Z et al (2021d) Performance amelioration of single basin solar still integrated with V- type concentrator: energy, exergy, and economic analysis. Environ Sci Pollut Res 28:3406–3420. https://doi.org/10.1007/s11356-020-10625-2

Tiwari AK, Tiwari GN (2006) Effect of water depths on heat and mass transfer in a passive solar still: in summer climatic condition. Desalination 195:78–94. https://doi.org/10.1016/j.desal.2005.11.014

Tiwari GN, Singh HN, Tripathi R (2003) Present Status of Solar Distillation 75:367–373. https://doi.org/10.1016/j.solener.2003.07.005

Tripathi R, Tiwari GN (2006) Effect of water depth on intemal heat and mass transfer for active solar distillation. Desalination 217:267–275

Vaithilingam S, Gopal ST, Srinivasan SK et al (2021) An extensive review on thermodynamic aspect based solar desalination techniques. J Therm Anal Calorim 145:1103–1119. https://doi.org/10.1007/s10973-020-10269-x

Velmurugan V, Deenadayalan CK, Vinod H, Srithar K (2008a) Desalination of effluent using fin type solar still. Energy 33:1719–1727. https://doi.org/10.1016/j.energy.2008.07.001

Velmurugan V, Gopalakrishnan M, Raghu R, Srithar K (2008b) Single basin solar still with fin for enhancing productivity. Energy Convers Manag 49:2602–2608. https://doi.org/10.1016/j.enconman.2008.05.010

Wang Z, Liu Y, Tao P et al (2014) Bio-inspired evaporation through plasmonic film of nanoparticles at the air-water interface. Small 10:3234–3239. https://doi.org/10.1002/smll.201401071

Yadav C, Kumar M (2016) Recent advances in stepped and weir type solar still. Int J Recent Adv Eng Technol 4:83–90

Yeh HM, Chen LC (1986) The effects of climatic, design and operational parameters on the performance of wick-type solar distillers. Energy Convers Manag 26:175–180. https://doi.org/10.1016/0196-8904(86)90052-X

Zalba B, Marín JM, Cabeza LF, Mehling H (2003) Review on thermal energy storage with phase change: materials, heat transfer analysis and applications

Zhou L, Tan Y, Wang J et al (2016) 3D self-assembly of aluminium nanoparticles for plasmon-enhanced solar desalination. Nat Photonics 10:393–398. https://doi.org/10.1038/nphoton.2016.75

Zhu M, Li Y, Chen F et al (2018) Plasmonic wood for high-efficiency solar steam generation. Adv Energy Mater 8:1–7. https://doi.org/10.1002/aenm.201701028

Zurigat YH, Abu-Arabi MK (2004) Modelling and performance analysis of a regenerative solar desalination unit. Appl Therm Eng 24:1061–1072. https://doi.org/10.1016/j.applthermaleng.2003.11.010

Acknowledgements

The authors are grateful to VNRVJIET for providing the time and facilities to write this article and also grateful to editors and reviewers for sparing their valuable time.

Author information

Authors and Affiliations

Contributions

Literature search, writing—original draft preparation: Shaik Afzal Mohiuddin; ideas, writing—review, editing, and supervision: Ajay Kumar Kaviti; supervision: T. Srinivasa Rao; writing—review and editing: Vineet Singh Sikarwar.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The authors have taken the permissions from all publishers.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The methodology was adopted for advances in internal design modifications of solar still.

• Historical and recent internal design modifications have been discussed exhaustively.

• Historical and recent modifications enhanced the distillate yield of up to 80% and 300%.

• Nanostructures, nanoparticles, and contactless structures are the current hotspots.

• Future perspectives in internal design modifications have been discussed.

Rights and permissions

About this article

Cite this article

Mohiuddin, S.A., Kaviti, A.K., Rao, T.S. et al. Historic review and recent progress in internal design modification in solar stills. Environ Sci Pollut Res 29, 38825–38878 (2022). https://doi.org/10.1007/s11356-022-19527-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19527-x