Abstract

Phosphorus is an important element for agriculture and industry, but its deposits are not uniformly distributed. Countries that do not have primary sources are dependent on imports or regeneration from secondary materials. A widely available secondary source is sewage sludge. Used environmental standards govern sludge treatment, but its inclusion in the raw material policy is often missing. We focus on the Czech Republic (a European Union member) and Japan, countries without phosphorus deposits. Based on our analysis of sewage sludge flows, legislation, and technologies used, we aimed to evaluate approaches towards sustainable phosphorus policy. We figured out that in the Czech Republic, sludge application to soil continues due to legislation deregulation and thus, various pollutants enter the soil along with the sludge. In Japan, thermal treatment predominates, but ash is not processed, and phosphorus is irreversibly lost in landfills or construction. By not implementing a functional P-recovery policy, both countries lose more than 13 % replacement of phosphorus fertilisers from their sources.

Graphical Abstract

Similar content being viewed by others

Introduction

The scarcity of raw materials has led to materials that were previously considered waste coming to the fore. Today, sewage sludge is considered a source of phosphorus: one of the raw materials on the EU’s list of Critical Raw Materials (European Commission 2020). Phosphorus is essential for agriculture and industry, but its price is increasing and resources are limited (IndexMundi 2023; Zhang 2019). Therefore, P-recovery technologies are becoming more critical as phosphorus supplies become scarcer and prices rise. Phosphorus from sludge represents a way to ensure at least some self-sufficiency. However, it must be recovered in a pure (non-hazardous) form.

Traditional sludge disposal techniques, such as application to agricultural land, composting, or landfilling of sludge or residues after sludge thermal treatment, are beginning to be restricted in some countries (Bauer et al. 2020; Hudcová et al. 2019; Santos et al. 2021). In order to avoid the spread of pollutants in the environment (Huygens et al. 2022), an increase in antibiotic resistance (Hubeny et al. 2021; Jauregi et al. 2021), eutrophication (Kidd et al. 2007; McBride 2022), or losses of raw materials is observed. New sludge treatment technologies are being implemented, such as pyrolysis, carbonisation, and gasification. The proportion of mono-incinerated sludge is increasing, and P-recovery technologies are gaining strategic importance in the field of partially mitigating P import dependence (Hušek et al. 2022). The legislation can be considered to be the most significant driving force in sludge disposal (treatment). Bans, new limits, and strategies compel industry and research to look for new technologies that meet legislative requirements.

In this article, we present unpublished data on sewage sludge treatment from two different and contrasting countries: the Czech Republic and Japan. The countries differ in size, geography, legislation, approach to sewage sludge treatment, and the technologies used. The Czech Republic, a member state of the European Union, has long preferred to use sewage sludge directly on agricultural land. On the other hand, Japan has been indirectly using sludge for construction or landfilling in recent years.

Some countries, such as Germany and Switzerland, which do not have their own phosphorus sources, have made phosphorus recovery from the sludge use mandatory in their legislation to improve their raw material security. However, in our two target countries, this suitable policy is lacking. Therefore, we expect that current Japanese and Czech sludge treatment strategies are insufficient to achieve at least partial self-sufficiency in phosphorus production.

Literature review

Sewage sludge is generated during wastewater treatment and contains organic matter (Carabassa et al. 2018; Romanos et al. 2019), nitrogen (Deviatkin et al. 2019; Munasinghe-Arachchige et al. 2020), phosphorus (Meng et al. 2019; Yu et al. 2021), and various pollutants such as heavy metals (Buta et al. 2021; Chu and He 2021), pharmaceuticals (Ivanová et al. 2018; Silva et al. 2021), endocrine disruptors including hormones (Černá et al. 2022; Šauer et al. 2021; Wang et al. 2020), PFASs (Fredriksson et al. 2022; Kim Lazcano et al. 2019; Semerád et al. 2020), PAHs (Sun et al. 2019; Tomczyk et al. 2020), pathogens (López et al. 2020; Romanos et al. 2019), and microplastics (Corradini et al. 2019; Koyuncuoğlu and Erden 2021; Pim van den Berg et al. 2020). The presence of pollutants makes direct application on soil imprudent and determines the level and methods of sludge disposal (treatment), considering the standards for environmental protection and raw material conception (P-recovery) in a given country.

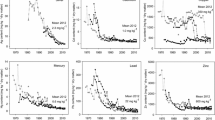

Sludge disposal (treatment) methods have long been presented at the level of statistical offices or agencies with an environmental interest, for example, ANZBP (2022), CENSTATD HK (2018), Eurostat (2022), or US EPA (2022). However, a trend in applied science and research has also been observed in recent years, with individual scientists publishing papers with a focus on sewage sludge treatment from countries of their interest in the field of sludge material flows, composition, post-treatment products (ash and sludge-char), available technologies and their limitations, and legislation with a frequent focus on phosphorus content and P-recovery. Amann et al. (2022) described sludge treatment methods for more than 600 WWTPs (wastewater treatment plants) in Austria with more than 2000 population equivalents (PE). Most of the phosphorus ended up in landfills or landscaping where it was not used adequately. The heavy metals in the applied sewage sludge still contributed to the contamination (loading) of agricultural soils at a rate of approximately 20 % of the heavy metals contained in the wastewater. According to Krüger and Adam (2015), approximately 13 % of German phosphate rock-based mineral fertilisers could be replaced after ash treatment from operating sewage sludge mono-incineration. However, as a prerequisite, the ash must be safely processed in P-recovery plants due to heavy metal content and low P bioavailability. In general, thermal treatment of sewage sludge has long been the predominant method in Germany, accounting for more than 70 % (mono- and co-incineration, cement plants, or incinerators) since 2018 (Destatis 2023; Schnell et al. 2020). In the future, it is expected that the amount of sludge incinerated in mono-incineration plants will increase at the expense of other plants (e.g. cement, co-incineration, or waste) to recover phosphorus (Schnell et al. 2020). Smol et al. (2020a) analysed sludge ash from 6 of 11 mono-incineration plants in Poland for the content of 25 different elements, of which the phosphorus content of the ash ranged from 7 to 13 %. Other articles on the Poland issue were published by Przydatek and Wota (2020), Rosiek (2020), Vambol et al. (2023), or Smol et al. (2020b). Chen et al. (2021) published a comprehensive analysis of dewatered sewage sludges from 32 different WWTPs in Japan with an average P content in sewage sludge of 2.8 % ± 0.7 % (digested and undigested). On the contrary, in China, according to Wang et al. (2018), the average phosphorus content of sewage sludge was 1.7 % ± 0.5 %. Furthermore, many other country case studies have been published in the field of sewage sludge treatment, for example, Bhutan (Dorji et al. 2019), Croatia (Đurđević et al. 2022, 2019), Egypt (Abdel Wahaab et al. 2020), France (Munoz et al. 2022; Pradel 2019), Italy (Campo et al. 2021; Mininni et al. 2019), Morocco (Ghacha et al. 2020), and Nigeria (Nikolopoulou et al. 2023).

Compared to our target countries, a phosphorus recovery strategy has been implemented in Switzerland and Germany. In Switzerland, sludge application on agricultural land is prohibited (Schinkel et al. 2022), and phosphorus recovery from sludge and sludge ash is mandatory from 2026 (Mehr et al. 2018). Germany forces the implementation of P-recovery strategies for WWTP operators, depending on the plant size. Plants over 100,000 population equivalent (PE), with phosphorus in dry matter > 2 %, will be required to recover phosphorus in 2029, and it will not be possible to apply sludge on agricultural land. From 2032, the same will apply to installations above 50,000 PE (Mayer et al. 2021; Sichler et al. 2022). In Austria, new legislation is being prepared, which, if approved, would make sludge incineration and P-recovery mandatory for WWTPs above 20,000 EO from 2030 (European Commission 2022). We believe that P-recovery must be superordinate to other sewage sludge treatment methods to secure critical supplies for industry and consumer protection.

Methodology

Data on sewage sludge production and treatment were taken from the Czech Statistical Office (CZSO) and the Japan Sewage Works Association (JSWA). Data are based on a statistical survey of economic entities of interest (reporting units) for a given calendar year or, in the case of JSWA, for the fiscal year (FY = April to March). The fiscal year 2015 is the period of 1.4.2015–31.3.2016 and 2020 1.4.2020–31.3.2021. The production and processing tables published in the JSWA format are in the Supplementary Materials (STable 1). The data in Table 2 were validated, paired, and recalculated for use in this article. The thermal product quantity and treatment statistics in Chapter 4.3.2 are only from the state-owned Japanese facilities. Data from the private sector are not available.

The legislation of interest was the laws and decrees concerning the management of sewage sludge and other products made from it (compost, ash, slag, or sludge-char). An overview of the technologies used was based on local knowledge, stakeholder consultation, and, in Japan, additionally on the JSWA Yearbook for FY2020 (JSWA 2022).

The amount of phosphorus in Czech sewage sludge was determined according to the anaerobic sludge screening test by Mercl et al. (2018), with an average P content of 2.59 wt.% in dry matter. Similarly, the phosphorus content of Japanese sludge was set from a publication by Chen et al. (2021): in undigested sludge, the P content in dry matter was 2.36 wt.% and in digested sludge 3.40 wt.%. In the Czech Republic, anaerobic stabilisation is widely used due to legislative limits for the content of microorganisms in medium and large WWTPs. In Japan, approximately one-third of sludge is anaerobically treated (JSWA 2022); therefore, a value for the undigested sludge = 2.36 wt.% P in dry matter was used. Data on phosphorus fertiliser consumption, expressed in P2O5, were taken from CZSO and the International Fertilizer Association (IFA). A value of 2.29 was used to relate P to P2O5.

Results

Sludge production and treatment

Czech Republic

The amount of sewage sludge between 2015 and 2020 (resp. 2021) increased by more than 11 % (Table 1 and SFigure 1). The number of WWTPs influences the increase, along with the total capacity of the WWTPs (day.m−3), BOD5 (t.year−1), and the number of people connected to the sewer network. In the long term, two-thirds of the sludge is processed by direct application in agriculture or composting. Less than 10 % is still landfilled and the amount of incinerated sludge is gradually increasing (CZSO 2022a, 2021, 2016). Sludge is co-incinerated (electricity and heat or cement production) or pyrolysed (from 2020 in a unit at the WWTP Bohuslavice–Trutnov (Fuka et al. 2021)). Currently, there is no sludge mono-incineration plant in operation. Most of the sludge presented in the statistics is treated anaerobically. Anaerobic stabilisation is relatively common in medium and large WWTPs, as a result of legislative requirements (see Chapter 4.2) and a long tradition of its use.

Japan

Municipalities and the private sector treat sewage sludge thermally, in soil, or in some other way (construction, landfills, or another way). Thermal treatment exceeds any other method and is the critical treatment method for Japanese sewage sludge (Table 2 and SFigure 2). Thermal treatment also has implications for the large production of thermal products such as ash, carbonatised sludge, or slag, which have the potential for secondary use (Chapter 4.3.2). The treatment of sludge that has not been anaerobically stabilised at WWTP remains predominant (JSWA 2022).

The approaches of the two countries are opposed. The Czech Republic prefers direct use (compost and agriculture), and the administration has still not managed to divert sludge from landfills. Japan’s predominant approach is thermal treatment (mono-incineration, co-incineration, cement production, melting, or carbonisation).

Regarding statistics and their formation, the Czech one is relatively simple, but limited by the number of respondents. Japanese is broad, but with insufficient linkage to the private sector and data validation on a pan-Japanese scale. Both lack a comprehensive and valid approach presenting the total material flow: from primary sludge producers to processors (bigger WWTP, thermal, or compost plants) and place utilisation or disposal. However, the attitude to implementing such a policy, the way statistics are kept, is the responsibility of public administration (government).

Legislation

Limits for the use of sewage sludge on agricultural land

The use of sewage sludge on agricultural land is allowed in both the Czech Republic and Japan. In the field of sewage sludge treatment, the Czech Republic’s legislation, as a member state of the European Union (EU), is based on Directive 86/278/EEC, which sets limits for individual pollutants (only heavy metal) in sludge (Table 3) and the soil on which the sludge will be applied. Individual member states may tighten and extend their limits beyond those set out by the European Union. The Czech Republic tightened its limits for heavy metals and established limits for organic pollutants and pathogens (Table 3 and STable 2); the maximum sludge dose is 5 tDM.ha−1 once every three years or 10 tDM.ha−1 if the pollutant content is half (Regulation No. 273/2021 Coll.). Limits for pollutant content in the soil can be found in STables 3 and 4—Supplementary Materials, along with a list of other restrictions (areas, agriculture type, or soil pH).

Japan has limits for the agricultural use of sewage sludge that apply to heavy metals. Organic pollutants and pathogens have no direct limits (Table 3). However, sludge must meet the judgement criteria for industrial waste containing metal and other contaminants—leaching test (STable 5) and plant damage test—ecotoxicology (see Supplementary Materials). Following the accident at the Fukushima Daiichi Nuclear Power Plant, a limit for radioactive Cs was introduced in selected prefectures (MAFF 2022a, 2012). Doses and applications are not restricted and sludge can be applied to fields where crops are grown. The amount of selected pollutants in the soil (STable 6) has a target level (environmental standards), but the testing frequency is not specified (Environmental Agency Notification No. 46).

Japan and the Czech Republic have a similar approach to heavy metal limits. The Czech Republic also directly limits the content of certain organic pollutants (PCBs, PAHs, and AOX) and pathogenic organisms (Salmonella sp., Escherichia coli/enterococci, and thermophilic coliform bacteria) depending on the sludge category. Japan, in addition, controls the content of radioactive Cs in selected prefectures and establishes a plant damage test and leachate test (heavy metals and a range of organic pollutants). Other organic pollutants that are not monitored in Czech sludge, unlike other countries, include nonylphenols, bis(2-ethylhexyl) phthalate, linear alkylbenzene sulphonates, PFASs, or dioxins and furans (Collivignarelli et al. 2019; Gianico et al. 2021). Current Japanese and Czech limits (tests) do not control the long-term accumulation of persistent substances such as antibiotics, PFASs, or microplastics that can accumulate in the environment and additionally cause problems for plants, animals, or human health (food chain) (Bolan et al. 2021; Buta et al. 2021; Hušek et al. 2022). The lack of a maximum application rate and the absence of regular soil monitoring for heavy metals after sludge application in Japan may also contribute to heavy metal accumulation (Swain et al. 2021).

Limits for the use of compost with sewage sludge in agriculture

Czech legislation regulates compost use, depending on the location, by two decrees (Regulation), resulting in inconsistent legislative requirements. Composts intended for green areas in sports and recreational facilities (Group II, Class I) are controlled in more parameters and more strictly than composts for agricultural and forest land (Group I) (STable 7). The Japanese legislation deals with the quality of compost in a similar way to that of sewage sludge for direct use on soil (Chapter 4.2.1). The individual applicable limits and quality requirements for sludge composts are given in the Supplementary Materials in Chapter 2.2. In neither case are the limits for halogenated organics or antibiotic resistance genes limited, which are not sufficiently degraded during composting (Lü et al. 2021).

Limits for ash, sludge-char, and slag in agriculture

The Czech Republic and Japan allow and use sludge ash, char, and slag in the soil. Both regulate the content of heavy metals and selected organic pollutants (direct limits or leachate test)—Supplementary Materials Chapter 2.3. These thermally treated sludge products are an alternative to direct application and compost production as a source of phosphorus for plants. With proper operation (sufficient temperature and residence time), organic pollutants are removed (Alipour et al. 2022; Kwapinski et al. 2021). However, heavy metal concentration in ash and char is one of the obstacles, along with the low bioavailability of phosphorus (Hauck et al. 2022; Herzel et al. 2016; Krüger et al. 2014). Therefore, replacing conventional commercial P-fertilisers with these thermal products is problematic. We believe that the ash should only be an intermediate product between the sludge mono-incineration and P-recovery processes. Sludge-char (pyrolysis product) should be produced from sludge with a low heavy metal content at a temperature of at least 500 °C (ideally 600 °C) to sufficiently remove organic pollutants (Buss 2021; Moško et al. 2021a, b). Sludge-char used in agriculture is still questionable: although the sludge used for production has a low heavy metals content, metals are still present. For this reason, sludge-char should be used primarily as a soil improver in soil reclamation (mines or old environmental loads) where there is no risk of widespread primary contamination.

In contrast to Switzerland or Germany, neither the Czech Republic nor Japan has introduced a strategy for P-recovering. Sludge as a fertiliser does not achieve similar results to commercial fertilisers (Christiansen et al. 2020; Lemming et al. 2017). Tools to recover phosphorus in a pure, uncontaminated form are not legislated. Losses of phosphorus to landfills, ash (co-incineration), or construction commonly occur.

Sludge (thermal) treatment and P-recovery technologies in use

Sludge thermal treatment and P-recovery technologies are closely linked. Ash, after mono-incineration, presents input material to the processing plant. Slag or sludge-char are products after melting or pyrolysis (carbonisation) intended for direct use as a soil improver. According to the STRUBIAS report (Huygens et al. 2019), there are three different methods (categories) for manufacturing and placing fertiliser from biowaste and other secondary raw materials onto the EU market under Fertilising Products Regulation (Regulation (EU) 2019/1009). They are the precipitation of phosphate salts, thermal oxidation (also followed by wet chemical or thermal processes), and pyrolysis and gasification.

Czech Republic

Initially, the same microbiological criteria for composts (STable 8) were to be applied from January 1, 2023, for sludge used on agricultural land, increasing the pressure on WWTP operators to provide more advanced hygienisation methods such as dryers, incinerators, or pyrolysis units. However, the decree (Regulation No. 273/2021 Coll.) was amended at the end of 2022, and more benevolent pathogen limits were established (STable 2). This change (deregulation) maintains the status quo, yet several projects have been installed or begun construction (preparation).

Currently, a solar dryer (Mariánské Lázně), four low-temperature dryers (Přerov, Karlovy Vary-Drahovice, Šumperk, and Bohuslavice–Trutnov), and a pyrolysis unit (Bohuslavice–Trutnov) are in operation. The dryer in the Brno-Modřice WWTP is being prepared to replace the paddle dryer with a low-temperature dryer. Four more low-temperature dryers are under construction, and others are in preparation, including a pyrolysis unit (Tábor). Supplementary Materials (STable 12 and SFigure 3) give their locations and a general overview. After legislative amendment, the reason for constructing such facilities for the WWTP operators remains sludge weight reduction. Our investigation shows that operators expect to use dried sludge in incineration units. There is no sludge mono-incinerator, compared to few thermal technologies in operations co-incinerate sludge. Therefore, irreversible losses in the ash of phosphorus contained in co-incinerated sludge can be expected. The pyrolysis unit at the Bohuslavice–Trutnov WWTP is the only technology for producing secondary material with high P content in the Czech Republic.

Japan

Unlike the Czech Republic, Japan has an extensive network of drying and thermal plants processing sewage sludge. The municipality and prefectures or the private sector operate the individual sludge terminals of the various WWTPs. Information is limited if the sludge is treated in the private sector. Therefore, we have focused primarily on municipal and prefecture-run plants and identified the generated products’ material flows, locations, and disposal methods.

Sludge thermal treatment

Drying units are present at many WWTPs as part of the processing chain or as an end-of-line technology. Flash dryers, indirect heat dryers, or hot air rotary dryers with stirrers are commonly used. Solar drying accounts for a minority share of total dry sludge production and is used mainly in southern Japan in Kyushu and Okinawa (JSWA 2022).

Sludge melting plants

Sewage sludge (ash) melting treatment is Japanese-specific: the shortage of raw materials and landfill sites. However, its share is gradually decreasing, with old units being decommissioned one by one at the end of their service life and new ones not being opened due to high energy consumption. In FY2020, six state-owned plants with 16 units were in operation. In comparison, 29 state-owned units were operated in FY2011. Nowadays, surface melting, coke bed melting, swirling melting, or a combination of pyrolysis + swirling ash melting are used JSWA (2022). The slag produced is used mainly in civil engineering (Table 4), resulting in phosphorus loss. Individual state plants’ capacity and location are in the Supplementary Materials (STable 13 and SFigure 4).

Carbonisation plants

The amount of treated sludge in carbonisation plants has increased by more than 95 % compared to 2015 (Table 2). Produced carbonised sludge is mainly used as a fuel substitute in coal-fired power stations (Table 5). Leading to the loss of phosphorus and the spread of present heavy metals into ash and flue gas. Depending on the plant, the sludge is carbonised at temperatures ranging from 300 to 880 °C. A portion of approximately 13 % is used in cement production. Direct (agricultural) use has a negligible share. Characteristics of individual plants in Supplementary Materials—STable 14 and SFigure 4. JSWA (2022).

Mono-incineration plants

Almost two-thirds of sludge is mono-incinerated in Japan (Table 2), and more than 155,000 tons of ash (sum of the own production and processed imported sludge) from state-owned mono-incinerators is produced yearly. Fluidised bed boilers are used in the vast majority (STable 15) because of their suitable properties for incinerated sewage sludge: high fuel and operation flexibility, easy control, and high process efficiency (Hušek et al. 2022). Most of the ash is used in the construction industry (47 %) or landfilled (36 %)—building artificial islands in the sea (28 %) or landfills (8.4 %) (Table 6), resulting in losses of phosphorus and other raw materials. Sludge ash contains a significant mineral content that can be used in construction (Ottosen et al. 2022), but this step should precede the regeneration of phosphorus and other substances. A list of individual state operations is available in the Supplementary Materials (STable 15 and SFigure 5) JSWA (2022).

Due to the change in legislation in the Czech Republic (loosening of microbial limits), the only motive to install thermal treatment, mainly drying, for WWTP operators remains weight reduction and thus reduction in the disposal fee. Capacities for mono-incineration are lacking. Dry sludge co-incineration with coal or biomass can be assumed in the medium term.

Japan already has a network of drying and mono-incineration plants supplemented by sludge carbonisation and melting plants. However, the products from these facilities are primarily diverted to the construction industry and landfills, which results in an irreversible loss of phosphorus. The implementation of a phosphorus management strategy is a necessity. The size and ruggedness of Japan and the spread of cities and conurbations will be an obstacle to implementing a single centralised approach. Nevertheless, through centralisation and cooperation at the prefectural level and between the private and municipal sectors, it would be possible to find an effective solution for the location of P-recovery facilities complemented by existing carbonisation and melting plants. Slag and carbonised sludge (char) should be certified as a soil improvement. If carbonised sludge or slag does not meet the limits, it should be treated in the mono-incinerator with the sludge. The construction industry should subsequently be linked to P-recovery plants and use residual mineral content.

P-recovery technologies

Some P-recovery technologies are already used in Japan, although their share is a minority. Two groups of technologies are generally used to extract phosphorus and produce phosphorus-rich materials: struvite precipitation (sludge and wastewater) and sludge thermal treatment into products (char and slag) or intermediate products (ash) processed in P-recovery technology. The first group includes the technologies in Kobe, digested sludge treatment to form struvite (Koga 2019), Fukuoka, and Matsue, extraction of struvite from water after digested sludge dewatering (Nättorp et al. 2019). The second group (article focus) includes Nippon Phosphoric Acid Co. (NPA), Kubota, and Metawater Co. (Ohtake and Tsuneda 2018). During the NPA process (the current state could not be verified), sludge ash is mixed with the phosphorus rock at a maximum dose of 2.5 wt% treated in a sulphuric acid solution. The ash dose is limited to avoid affecting the production or contaminating phosphoric acid and gypsum products. For more information on the process, see Mochiyama (2019).

The Kubota process is based on sludge (ash) treatment in a melting furnace. The sludge (ash) is treated at high temperatures (around 1300 °C) to form a slag in which 90 % phosphorus is covered. Organic pollutants are decomposed, and heavy metals are volatilised and collected in exhaust gas treatment. Subsequently, the slag produced could be used as a P-fertiliser. However, slag is currently only used in civil engineering (asphalt filter, backfill, or secondary concrete product), resulting in irreversible losses in phosphorus. Registration of slag as a fertiliser or soil improver is required. The preparatory stages for fertiliser production at the facilities are underway in Toyama Prefecture (Nijo Wastewater Treatment Centre and Left Bank of the Jinzu River). A more detailed description of the technology is available in Hosho (2019).

The latest technology comes from Metawater Co., which has plants in Gifu City and Tottori (occasional operation), where P-recovery lines are installed. The ash is mixed with NaOH and raised solution (without solid particles) with Ca(OH)2 to form Ca3(PO4)2. The resulting product is processed: washed, dried, and sold in the form of calcium hydroxyapatite with a process efficiency of 30–40 %. The product is used as an ingredient in commercial fertilisers (from Gifu City named Gifu-no-daichiⓇ). Annual production in Gifu is around 100 tons of P-product from processed sludge ashes from Gifu City. The solid residue, after processing, is treated with a sulphuric acid solution to remove heavy metals. Solid-treated residues can be used as a construction material. For a more in-depth description of the technology, see Nakagawa and Ohta 2019 and Sonoda 2019.

For technologies in which struvite is precipitated, it must be ensured that it complies with the applicable limits. However, struvite may contain pollutants (inorganic, organic, or microplastics) transferred from wastewater or sludge. From our perspective, struvite should be processed by P-recovery plants as soon as these facilities are available, producing uncontaminated fertiliser or pure H3PO4. Unlike ash, struvite will not contain a significant ballast mineral content.

In commercial technologies (phosphate rock processing), heavy metals in the ash present a problematic issue (Langeveld 2019; Schipper 2019). Limiting the amount of ash dose is necessary to ensure that the metals do not affect the production process and product quality. Pyrolysis, with its smaller capacity and ability to concentrate heavy metals in char (Mancinelli et al. 2016; Zhang et al. 2021), is a suitable technology for remote areas with annual sludge production of at least 500tDM where the sludge is not burdened by heavy sludge. Unlike melting furnaces, which allow the processing of large quantities of sludge to form slag without heavy metal pollution and with bioavailable phosphorus (high citric acid-solubility and pot test—Hosho (2019)). However, the high operating temperature of the melting furnaces and associated running and equipment costs present a limitation. Strangely, if phosphorus is bioavailable (Hosho 2019) and heavy metals are removed, slag is not used as a fertiliser in agriculture today in Japan, but finds its application in the construction industry, where phosphorus is irreversibly lost. Wet chemical ash treatment by Metawater Co. after sludge mono-incineration is a long-used technology in Japan, characterised by lower efficiency but long-lasting operation. In Europe, an increase can be seen in the use of wet-chemical technologies that treat sludge ash after mono-incineration to obtain phosphorus in acid or solid form together with other raw materials (minerals, silica sand, gypsum, iron or aluminium salts, and heavy metal concentrates) (Hušek et al. 2022). However, the technologies in operation are limited in number as opposed to the number in semi-operational or research scale, but their development can be expected in the future as individual state P-strategies are adopted and will come into force (ESPP et al. 2023).

P-recovery technologies represent an additional cost in wastewater treatment (Nättorp et al. 2017), and their implementation in commercial forms is still being implemented (ESPP et al. 2023). A sufficient and clearly defined transition period is needed to allow the private and public sectors to prepare. In Germany, the transition period ends in 2029 for the largest WWTPs (over 100,000 PE) (Sichler et al. 2022) and Switzerland introduces an obligation to recover phosphorus from sludge and sludge ash from 2026 (Mehr et al. 2018). Although Japan produces significant amounts of ash, it does not have such legislation. Ash is mainly landfilled or processed in the construction industry. We believe that ash storage should be initiated for the necessary time before the required P-recovery technologies are built to prevent its loss.

Sludge composition

The presence of different elements in the sewage sludge is not uniform and is influenced by many variables, for example, coagulants used at WWTP (Fu et al. 2021; Ooi et al. 2018), industry (Hubeny et al. 2021; Lee et al. 2019; Sundha et al. 2022; Tytła, 2019), healthcare (Ajala et al. 2022; Ajibola and Zwiener 2022; Mackuľak et al. 2019), season (Arhoun et al. 2019; Kasina et al. 2017; Uogintė et al. 2022), or the buildings and households themselves (Dokulilová et al. 2018; Hoang et al. 2022; Tang et al. 2020).

The composition of the sludge can also be changed by mixing it with other sludge at the WWTP. In the Czech Republic, sludge from small WWTPs sludge that do not have technologies for sludge hygienisation and stabilisation is mixed with untreated sludge at medium or larger WWTPs. Subsequently, it is processed with local sludge to meet hygiene parameters, and because the added sludge has a different composition, the overall composition changes.

Compared to the unique pollutant content of each WWTP, the phosphorus content can be generalised. Because the phosphorus occurrence depends on human faeces (Harder et al. 2019) and the amount of detergents containing phosphorus used (Ekman Burgman and Wallsten 2021) and not on local specificities. Phosphorus becomes part of biomass (activated sludge) during biological water treatment by incorporation into biomass and chemical precipitation (if used). The final phosphorus content can vary depending on the technologies used (e.g. chemical precipitation), plant size due to the stricter discharge water quality requirements for medium and large WWTPs (higher P removal efficiency is required) (Directive 91/271/EEC), or anaerobic sludge stabilisation (concentration in sludge, recirculation of sludge water) (Kroiss et al. 2011; Morse et al. 1998; Wang et al. 2014). Using a P-free detergent, a certain reduction in the phosphorus load on WWTP from this source can be expected (Chen et al. 2022; Puijenbroek et al. 2019).

P-recovery rate

To calculate the possible amount of recoverable phosphorus (Table 7), we considered the intended Austrian model based on mono-incineration followed by wet chemical treatment: from January 1, 2030, sewage sludge incineration and P-recovery will be mandatory (if approved) for Austrian WWTPs with more than 20,000 PE. The P-recovery rate from the ash must be at least 80 % or, alternatively, recovery of 60 % of the P influent is necessary at WWTP (European Commission 2022).

We assume the amount of sludge treated in this way to be 75 %, primarily from large and medium WWTPs. Due to disproportionate transport costs or small production, a part of the sludge (the remaining 25 %) will be treated in other ways by melting and pyrolysis (carbonisation) or local use (agriculture or land reclamation). The average amount of phosphorus in sludge for the calculation was 2.59 wt.% in dry matter for the Czech Republic (Mercl et al. 2018) and 2.36 wt% P in dry matter for Japan (Chen et al. 2021).

Replacing more than 13 % of P2O5 fertiliser consumption is possible in both countries (Table 7). Depending on the technology, phosphorus can be recovered in different forms, such as H3PO4, mono/dicalcium phosphate, or directly as a commercial P-fertiliser. Other raw materials co-produced with phosphorus may include iron or aluminium compounds, metal concentrate, gypsum, or minerals (treated ash). Aluminium or iron components can be reused as coagulates in WWTPs, mineral fractions in the construction industry, or cement production. Compared to the direct use of ash in construction, the mineral output of P-recovery is not contaminated because the technologies in the preparation already allow the concentration of heavy metals outside the mineral fraction. More information on P-recovery technologies is described in our review by Hušek et al. (2022).

Discussion

It cannot be assumed that there will be similar restrictions on using sewage sludge on agricultural land in Japan and the Czech Republic as in the Netherlands or Switzerland (Bauer et al. 2020; Mehr et al. 2018). In our opinion, approximately 25 % of sludge will always be treated in a way other than mono-incineration, either due to high transport costs, other thermal methods in use, or the application of sludge from small WWTPs to land (< 20,000 PE), where it will be possible to hygienise the sludge. From our point of view, these sludge and the sludge compost produced should be tested for pathogens (guaranteed hygienisation), heavy metals, total elements such as Br and F (indicative of flame retardants, PFASs, pesticides, and pharmaceuticals), and selected organic pollutants (PCBs, PAHs, PFASs, and AOX). At the same time, limits for microplastic content should be introduced once a validated methodology (Koyuncuoğlu and Erden 2021) for their determination has been created and adopted. For thermal products, it is necessary to maintain limits for heavy metals and selected organic pollutants (PAHs and PCBs), the detection of which would indicate poor functioning of the thermal unit. For pyrolysis, we recommend a minimum temperature of 500 °C, with a nominal output at 600 °C and a minimum sludge/sludge-char residence time of 10 min in the pyrolyser (Moško et al. 2021a, b). In addition to the removal of organic pollutants, sludge-based biochar with sufficiently developed structural properties (porous properties) can be produced under such conditions (Moško et al. 2021b). At the same time, the energy of the primary pyrolysis gas can be used to meet the energy requirements of pyrolysis with excess heat available for sludge pre-drying. However, mono-incineration should remain the basis of the entire sewage sludge treatment system: a primary, centralised, thermal treatment of large quantities of sludge to produce an ash suitable for treatment in P-recovery technology.

After deregulation of the legislation in the Czech Republic, the discussion of the issue of sewage sludge thermal treatment has been muted, affecting the introduction of P-recovery technologies and strategy. The lack of legislative support and concepts for critical resource management and concern for soil conservation will hardly convince the private sector and municipalities to invest into new technologies, with a typical higher gate fee, beyond established standards. The use of sewage sludge on agricultural land and composts can be expected to persist. In comparison, Japan’s dependence on imported phosphorus (phosphate rock) and its increasing price have led to the formation of a study group under the Ministry of Land, Infrastructure, Transport and Tourism (see MLIT 2022) to address the broader use of sewage sludge on agricultural land to provide more organic matter and phosphorus for soil (plants). However, based on current developments, the prevailing tendency is to deregulate sewage sludge used on agricultural land at the expense of the use and process of products after sludge thermal treatment to form raw P-products or soil improvers (slag or char). To date, the MLIT group has relied on examples of good practices from Japan: sludge application, compost production, or working P-recovery technology. Heavy metals are seen as an obstacle beyond farmers’ mistrust. However, the issue of organic pollutants, microplastics, and pathogens is not addressed. In our opinion, neglecting other pollutants present in the sludge will lead to their further spread into the environment. Sludge as a fertiliser does not achieve similar results to commercial fertilisers (Christiansen et al. 2020; Lemming et al. 2017). The study group should focus more on obtaining clean raw materials, not deregulating the sludge policy, as in the Czech Republic. Developing a full-fledged P-recovery strategy addressing the diversion of post-thermal treatment products from construction to agriculture directly (certified char and slag) or indirectly through P-recovery treatment plants (ash) should be a priority. Fertiliser products of recovered phosphorus (TSP, NPK, PK, or P) can then be better dosed and thus reduce phosphorus consumption according to precision agriculture principles. In case of a lack of organic matter in the soil, it is necessary to introduce and improve the collection of biowaste and gastro-waste to produce quality composts and digestates without pollutants content suitable for application to agricultural land.

Further research should focus on implementing new materials in P-recovery technologies, proving the safety of input and output products, and working in partnership with the private sector to continue to develop and improve P-recovery technologies. Other secondary P-sources considered are meat and bone meal ash (Coutand et al. 2008; Leng et al. 2019) or old fire extinguishing powder (Dotelli and Viganò, 2020; Nwoba and Moheimani 2022). Their incorporation into P-recovery technologies is needed. Especially the meat and bone meal ash from category I is currently not used because the ash from its incineration cannot be used (in Europe) due to the precautionary principles of prion disease (TSEs) (Bakalár et al. 2022; Regulation 1069/2009/EC). It must be demonstrated that incineration destroys organic matter, including TSEs, and that it is possible to process the ash together with the ash from the sludge incineration. Furthermore, the use of recovered phosphorus from waste materials in the food industry is currently not allowed at the EU level (Regulation 767/2009/EC)—use in another (technical) industry is not limited. The suitability of the process chain, safety of the recovered phosphorus, and list of input secondary raw materials for P-recovery products usable in the food industry must be validated and defined.

In addition to legislative support and raw material concept, it is necessary to plan the construction of thermal sludge treatment capacities and P-recovery plants to be used and not compete disproportionately. Individual P-recovery technologies should be evaluated depending on efficiency, cost of operation, energy and chemical consumption, environmental impacts, or the variety and type of products generated. An example of such an evaluation (plan) is in Switzerland (Morf 2018; Nättorp et al. 2019; Spörri et al. 2021). Cooperation between the municipality, local authorities, government, and private sector is essential for a properly set-up system operating with the local product utilisation without burdening the environment and the transport budget. Transportation between plants can have a negative impact on the surrounding area and the environment and increase the cost of the entire process, so planning the entire system based on the principles of industrial ecology and smart cities is essential.

Conclusion

Material recovery of sewage sludge on land and compost can no longer be considered beneficial. Not only that sludge contains many pollutants besides organic matter and nutrients, but mainly because it cannot sustainably replace commercial fertilisers. Sludge today represents a source of energy and phosphorus that must be adequately recovered (regenerated), which is crucial for raw material security.

Japan and the Czech Republic are dependent on imports of phosphorus and phosphate rock. Their availability on the market may change, becoming the subject of geopolitical struggle, threatening the competitiveness of industry and agriculture, and leading to higher food prices. The direct application of sludge and sludge composts does not produce the same results as the application of industrial fertilisers, while the contaminants in the sludge spread to the environment. Therefore, thermal treatment is necessary to ensure the removal or capture of contaminants and to obtain a product allowing P-recovery (ash) or direct use (char or slag).

The potential for P-recovery from mono-incinerated sludge is greater than 13 % of current phosphate fertiliser consumption in the Czech Republic and Japan, depending on the P-recovery efficiency and sludge quantity. However, not a single country is exploiting this potential. The Czech Republic has increased (deregulated) the previously proposed limit for pathogens in the sludge; therefore, there has been no change (necessity) to use thermal technologies to treat the sludge widely. In Japan, thermal methods are predominant, but the resulting products are not used for P-recovery but in construction or landfilled. Currently, there is talk in Japan about deregulating the direct use of sludge (sludge compost) in agriculture, which, from our point of view, would result in the spread of contaminants from the sludge into the soil. A strategy to include the intermediate step of P-recovery between thermal treatment and processing in the construction industry is lacking. The current distribution of mono-incineration plants in Japan is not uniform but makes it relatively easy to identify where immediate investment in P-recovery processing plants is possible.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Abdel Wahaab R, Mahmoud M, van Lier JB (2020) Toward achieving sustainable management of municipal wastewater sludge in Egypt: the current status and future prospective. Renew Sustain Energy Rev 127:109880. https://doi.org/10.1016/j.rser.2020.109880

Ajala OJ, Tijani JO, Salau RB, Abdulkareem AS, Aremu OS (2022) A review of emerging micro-pollutants in hospital wastewater: environmental fate and remediation options. Results Eng 16:100671. https://doi.org/10.1016/j.rineng.2022.100671

Ajibola AS, Zwiener C (2022) Occurrence and risk assessment of antibiotic residues in sewage sludge of two nigerian hospital wastewater treatment plants. Water Air Soil Pollut 233:405. https://doi.org/10.1007/s11270-022-05875-4

Alipour M, Asadi H, Chen C, Besalatpour AA (2022) Fate of organic pollutants in sewage sludge during thermal treatments: elimination of PCBs, PAHs, and PPCPs. Fuel 319:123864. https://doi.org/10.1016/j.fuel.2022.123864

Amann A, Weber N, Krampe J, Rechberger H, Peer S, Zessner M, Zoboli O (2022) Systematic data-driven exploration of Austrian wastewater and sludge treatment-implications for phosphorus governance, costs and environment. Sci Total Environ 846:157401. https://doi.org/10.1016/j.scitotenv.2022.157401

ANZBP (2022) Australian Biosolids Statistics. Biosolids. https://www.biosolids.com.au/guidelines/australian-biosolids-statistics/. Accessed 1 Nov 2022

Arhoun B, Villen-Guzman M, Gomez-Lahoz C, Rodriguez-Maroto JM, Garcia-Herruzo F, Vereda-Alonso C (2019) Anaerobic co-digestion of mixed sewage sludge and fruits and vegetable wholesale market waste: composition and seasonality effect. J Water Process Eng 31:100848. https://doi.org/10.1016/j.jwpe.2019.100848

Bakalár T, Pavolová H, Šimková Z, Bednárová L (2022) Phosphorus management in Slovakia—a case study. Sustainability 14:10374. https://doi.org/10.3390/su141610374

Bauer T, Burgman LE, Andreas L, Lagerkvist A (2020) Effects of the different implementation of legislation relating to sewage sludge disposal in the EU. Detritus. https://doi.org/10.31025/2611-4135/2020.13944

Bolan N, Sarkar B, Vithanage M, Singh G, Tsang DCW, Mukhopadhyay R, Ramadass K, Vinu A, Sun Y, Ramanayaka S, Hoang SA, Yan Y, Li Y, Rinklebe J, Li H, Kirkham MB (2021) Distribution, behaviour, bioavailability and remediation of poly- and per-fluoroalkyl substances (PFAS) in solid biowastes and biowaste-treated soil. Environ Int 155:106600. https://doi.org/10.1016/j.envint.2021.106600

Buss W (2021) Pyrolysis solves the issue of organic contaminants in sewage sludge while retaining carbon—making the case for sewage sludge treatment via pyrolysis. ACS Sustain Chem Eng 9:10048–10053. https://doi.org/10.1021/acssuschemeng.1c03651

Buta M, Hubeny J, Zieliński W, Harnisz M, Korzeniewska E (2021) Sewage sludge in agriculture: the effects of selected chemical pollutants and emerging genetic resistance determinants on the quality of soil and crops—a review. Ecotoxicol Environ Saf 214:112070. https://doi.org/10.1016/j.ecoenv.2021.112070

Campo G, Cerutti A, Lastella C, Leo A, Panepinto D, Zanetti M, Ruffino B (2021) Production and destination of sewage sludge in the Piemonte region (Italy): the results of a survey for a future sustainable management. Int J Environ Res Public Health 18:3556. https://doi.org/10.3390/ijerph18073556

Carabassa V, Ortiz O, Alcañiz JM (2018) Sewage sludge as an organic amendment for quarry restoration: Effects on soil and vegetation. Land Degrad Dev 29:2568–2574. https://doi.org/10.1002/ldr.3071

CENSTATD HK (2018) C&SD: statistics on sludge disposal and treatment in Hong Kong [WWW Document]. https://www.censtatd.gov.hk/en/EIndexbySubject.html?pcode=FA100277&scode=420. Accessed 1 Nov 2022

Černá T, Ezechiáš M, Semerád J, Grasserová A, Cajthaml T (2022) Evaluation of estrogenic and antiestrogenic activity in sludge and explanation of individual compound contributions. J Hazard Mater 423:127108. https://doi.org/10.1016/j.jhazmat.2021.127108

Chen M, Oshita K, Mahzoun Y, Takaoka M, Fukutani S, Shiota K (2021) Survey of elemental composition in dewatered sludge in Japan. Sci Total Environ 752:141857. https://doi.org/10.1016/j.scitotenv.2020.141857

Chen X, Wang Y, Bai Z, Ma L, Strokal M, Kroeze C, Chen X, Zhang F, Shi X (2022) Mitigating phosphorus pollution from detergents in the surface waters of China. Sci Total Environ 804:150125. https://doi.org/10.1016/j.scitotenv.2021.150125

Christiansen NH, Sørensen P, Labouriau R, Christensen BT, Rubæk GH (2020) Characterizing phosphorus availability in waste products by chemical extractions and plant uptake. J Plant Nutr Soil Sci 183:416–428. https://doi.org/10.1002/jpln.202000015

Chu L, He W (2021) Toxic metals in soil due to the land application of sewage sludge in China: spatiotemporal variations and influencing factors. Sci Total Environ 757:143813. https://doi.org/10.1016/j.scitotenv.2020.143813

Collivignarelli MC, Abbà A, Frattarola A, Carnevale Miino M, Padovani S, Katsoyiannis I, Torretta V (2019) Legislation for the reuse of biosolids on agricultural land in Europe: overview. Sustainability 11:6015. https://doi.org/10.3390/su11216015

Corradini F, Meza P, Eguiluz R, Casado F, Huerta-Lwanga E, Geissen V (2019) Evidence of microplastic accumulation in agricultural soils from sewage sludge disposal. Sci Total Environ 671:411–420. https://doi.org/10.1016/j.scitotenv.2019.03.368

Council Directive of 12 June 1986 on the protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture (consolidated version 01 January 2022), 2022

Council Directive of 21 May 1991 concerning urban waste water treatment (91/271/EEC) (consolidated version 28 December 2013), 2014

Coutand M, Cyr M, Deydier E, Guilet R, Clastres P (2008) Characteristics of industrial and laboratory meat and bone meal ashes and their potential applications. J Hazard Mater 150:522–532. https://doi.org/10.1016/j.jhazmat.2007.04.133

CZSO (2016) Water supply systems, sewerage and watercourses-2015 [WWW Document]. https://www.czso.cz/csu/czso/water-supply-systems-sewerage-and-watercourses-2015. Accessed 2 Nov 2022

CZSO (2021) Water supply systems, sewerage and watercourses-2020 [WWW Document]. https://www.czso.cz/csu/czso/water-supply-systems-sewerage-and-watercourses-2020. Accessed 2 Nov 2022

CZSO (2022a) Water supply systems, sewerage and watercourses-2021 [WWW Document]. https://www.czso.cz/csu/czso/water-supply-systems-sewerage-and-watercourses-2021. Accessed 2 Nov 2022

CZSO (2022b) Consumption of mineral fertilisers-tonne [WWW Document]. https://vdb.czso.cz/vdbvo2/faces/en/index.jsf?page=vystup-objekt&pvo=ZEM11&z=G&f=GRAFICKY_OBJEKT&skupId=2542&katalog=30840&pvo=ZEM11&ds=ds378&u=v309__VUZEMI__97__19#w=. Accessed 18 Nov 2022

Destatis, 2023. Disposal of sewage sludge by Land [WWW Document]. Federal Statistical Office. URL https://www.destatis.de/EN/Themes/Society-Environment/Environment/Water-Management/Tables/liste-disposal-sewage-sludge-land.html. Accessed 2 Feb 2023

Deviatkin I, Lyu L, Chen S, Havukainen J, Wang F, Horttanainen M, Mänttäri M (2019) Technical implications and global warming potential of recovering nitrogen released during continuous thermal drying of sewage sludge. Waste Manag 90:132–140. https://doi.org/10.1016/j.wasman.2019.04.031

Dokulilová T, Koutný T, Vítěz T (2018) Effect of zinc and copper on anaerobic stabilization of sewage sludge. Acta Univ Agric Silvic Mendel Brun. https://doi.org/10.11118/actaun201866020357

Dorji U, Tenzin UM, Dorji P, Wangchuk U, Tshering G, Dorji C, Shon H, Nyarko KB, Phuntsho S (2019) Wastewater management in urban Bhutan: assessing the current practices and challenges. Process Saf Environ Prot 132:82–93. https://doi.org/10.1016/j.psep.2019.09.023

Dotelli G, Viganò E (2020) Phosphate recovery from exhausted extinguishing powders: a case study of circular economy in the chemical industry. In: Maranghi S, Brondi C (eds) Life cycle assessment in the chemical product chain: challenges, methodological approaches and applications. Springer, Cham, pp 145–165. https://doi.org/10.1007/978-3-030-34424-5_7

Đurđević D, Blecich P, Jurić Ž (2019) Energy recovery from sewage sludge: the case study of Croatia. Energies 12:1927. https://doi.org/10.3390/en12101927

Đurđević D, Žiković S, Blecich P (2022) Sustainable sewage sludge management technologies selection based on techno-economic-environmental criteria: case study of Croatia. Energies 15:3941. https://doi.org/10.3390/en15113941

Ekman Burgman L, Wallsten B (2021) Should the sludge hit the farm?—How chemo-social relations affect policy efforts to circulate phosphorus in Sweden. Sustain Prod Consum 27:1488–1497. https://doi.org/10.1016/j.spc.2021.03.011

Environmental Agency Notification No. 46 August 23, 1991 [平成3年8月23日 環境庁告示第46号] (revised version 2020), 2020

ESPP, German Phosphorus Platform, Nutrient patfor NL, 2023. Catalogue of phosphorus recovery technologies [WWW Document]. https://phosphorusplatform.eu/activities/p-recovery-technology-inventory. Accessed 8 May 2023

European Commission (2020) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Critical Raw Materials Resilience: Charting a Path towards greater Security and Sustainability

European Commission (2022) Waste incineration regulation 2022 (AVV 2022)—2022/0645/A

Eurostat (2022) Sewage sludge production and disposal [WWW Document]. https://ec.europa.eu/eurostat/databrowser/view/ten00030/default/table?lang=en. Accessed 1 May 2023

Fertilizer Control Act (Act No. 127 of 1950 [肥料取締法 (昭和二十五年法律第百二十七号] (version Act No. 8 of 2007), 2007

Fredriksson F, Eriksson U, Kärrman A, Yeung LWY (2022) Per- and polyfluoroalkyl substances (PFAS) in sludge from wastewater treatment plants in Sweden—first findings of novel fluorinated copolymers in Europe including temporal analysis. Sci Total Environ 846:157406. https://doi.org/10.1016/j.scitotenv.2022.157406

Fu Q, Liu X, Wu Y, Wang D, Xu Q, Yang J (2021) The fate and impact of coagulants/flocculants in sludge treatment systems. Environ Sci Water Res Technol 7:1387–1401. https://doi.org/10.1039/D1EW00165E

Fuka J, Kos M, Pohorely M (2021) Drying and pyrolysis at Trutnov WWTP—the first results of test operation [Sušení a pyrolýza na ČOV Trutnov—první výsledky zkušebního provozu]. SOVAK 30:24–28

Ghacha A, Ammari M, Ben Allal L (2020) Sustainable sewage sludge management in Morocco: constraints and solutions. J Water Land Dev 46:71–83. https://doi.org/10.24425/jwld.2020.134199

Gianico A, Braguglia CM, Gallipoli A, Montecchio D, Mininni G (2021) Land application of biosolids in Europe: possibilities. Con-Straints Future Perspect Water 13:103. https://doi.org/10.3390/w13010103

Harder R, Wielemaker R, Larsen TA, Zeeman G, Öberg G (2019) Recycling nutrients contained in human excreta to agriculture: pathways, processes, and products. Crit Rev Environ Sci Technol 49:695–743. https://doi.org/10.1080/10643389.2018.1558889

Hauck D, Lohr D, Meinken E, Schmidhalter U (2022) Phosphorus availability from german sewage sludge ashes to plants cultivated in soilless growing media of contrasting pH. Agronomy 12:2610. https://doi.org/10.3390/agronomy12112610

Herzel H, Krüger O, Hermann L, Adam C (2016) Sewage sludge ash—a promising secondary phosphorus source for fertilizer production. Sci Total Environ Special Issue on Sustainable Phosphorus Taking stock: Phosphorus supply from natural and anthropogenic pools in the 21st Century 542, 1136–1143. https://doi.org/10.1016/j.scitotenv.2015.08.059

Hoang SA, Bolan N, Madhubashani AMP, Vithanage M, Perera V, Wijesekara H, Wang H, Srivastava P, Kirkham MB, Mickan BS, Rinklebe J, Siddique KHM (2022) Treatment processes to eliminate potential environmental hazards and restore agronomic value of sewage sludge: a review. Environ Pollut 293:118564. https://doi.org/10.1016/j.envpol.2021.118564

Hosho F (2019) Phosphorus recovery from sewage sludge by high-temperature thermochemical process (KUBOTA process). In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 189–199. https://doi.org/10.1007/978-981-10-8031-9_12

Hubeny J, Harnisz M, Korzeniewska E, Buta M, Zieliński W, Rolbiecki D, Giebułtowicz J, Nałęcz-Jawecki G, Płaza G (2021) Industrialization as a source of heavy metals and antibiotics which can enhance the antibiotic resistance in wastewater, sewage sludge and river water. PLoS ONE 16:e0252691. https://doi.org/10.1371/journal.pone.0252691

Hudcová H, Vymazal J, Rozkošný M (2019) Present restrictions of sewage sludge application in agriculture within the European Union. Soil Water Res 14:104–120. https://doi.org/10.17221/36/2018-SWR

Hušek M, Moško J, Pohořelý M (2022) Sewage sludge treatment methods and P-recovery possibilities: current state-of-the-art. J Environ Manag 315:115090. https://doi.org/10.1016/j.jenvman.2022.115090

Huygens D, Saveyn H, Tonini D, Eder P, Delgado Sancho L, European Commission, Joint Research Centre (2019) Technical proposals for selected new fertilising materials under the Fertilising Products Regulation (Regulation (EU) 2019/1009): process and quality criteria, and assessment of environmental and market impacts for precipitated phosphate salts & derivates, thermal oxidation materials & derivates and pyrolysis & gasification materials

Huygens D, García-Gutierrez P, Orveillon G, Schillaci C, Delre A, Orgiazzi A, Wojda P, Tonini D, Egle L, Jones A, Lugato E (2022) Screening risk assessment of organic pollutants and environmental impacts from sewage sludge management: study to support policy development on the Sewage Sludge Directive (86/278/EEC). JRC, LU

IFA (2023) IFASTAT|Consumption [WWW Document]. https://www.ifastat.org/databases/plant-nutrition. Accessed 22 Feb 2023

IndexMundi (2023) Rock Phosphate - Monthly Price - Commodity Prices - Price Charts, Data, and News - IndexMundi [WWW Document]. https://www.indexmundi.com/commodities/?commodity=rock-phosphate&months=240. Accessed 30 May 23

Ivanová L, Mackuľak T, Grabic R, Golovko O, Koba O, Staňová AV, Szabová P, Grenčíková A, Bodík I (2018) Pharmaceuticals and illicit drugs—a new threat to the application of sewage sludge in agriculture. Sci Total Environ 634:606–615. https://doi.org/10.1016/j.scitotenv.2018.04.001

Jauregi L, Epelde L, Alkorta I, Garbisu C (2021) Agricultural soils amended with thermally-dried anaerobically-digested sewage sludge showed increased risk of antibiotic resistance dissemination. Front Microbiol. https://doi.org/10.3389/fmicb.2021.666854

JSWA (2018) Sewer Statistics No. 72 [下 水 道 統 計 第 72 号]. JSWA, Tokio

JSWA (2022) Sewer Statistics No. 77 [下 水 道 統 計 第 77 号]. JSWA, Tokio

Kasina M, Kowalski PR, Michalik M (2017) Seasonal changes in chemical and mineralogical composition of sewage sludge incineration residues and their potential for metallic elements and valuable components recovery. Energy Procedia, European Geosciences Union General Assembly 2017, EGU Division Energy, Resources & Environment (ERE) 125:34–40. https://doi.org/10.1016/j.egypro.2017.08.049

Kidd PS, Domínguez-Rodríguez MJ, Díez J, Monterroso C (2007) Bioavailability and plant accumulation of heavy metals and phosphorus in agricultural soils amended by long-term application of sewage sludge. Chemosphere 66:1458–1467. https://doi.org/10.1016/j.chemosphere.2006.09.007

Kim Lazcano R, de Perre C, Mashtare ML, Lee LS (2019) Per- and polyfluoroalkyl substances in commercially available biosolid-based products: the effect of treatment processes. Water Environ Res 91:1669–1677. https://doi.org/10.1002/wer.1174

Koga D (2019) Struvite recovery from digested sewage sludge. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 255–264. https://doi.org/10.1007/978-981-10-8031-9_17

Koyuncuoğlu P, Erden G (2021) Sampling, pre-treatment, and identification methods of microplastics in sewage sludge and their effects in agricultural soils: a review. Environ Monit Assess 193:175. https://doi.org/10.1007/s10661-021-08943-0

Kroiss H, Rechberger H, Egle L (2011) Phosphorus in water quality and waste management. In: Kumar S (ed) Integrated waste management-volume II. IntechOpen. https://doi.org/10.5772/18482

Krüger O, Adam C (2015) Recovery potential of German sewage sludge ash. Waste Manag Urban Min 45:400–406. https://doi.org/10.1016/j.wasman.2015.01.025

Krüger O, Grabner A, Adam C (2014) Complete survey of German sewage sludge ash. Environ Sci Technol 48:11811–11818. https://doi.org/10.1021/es502766x

Kwapinski W, Kolinovic I, Leahy JJ (2021) Sewage sludge thermal treatment technologies with a focus on phosphorus recovery: a review. Waste Biomass Valor 12:5837–5852. https://doi.org/10.1007/s12649-020-01280-2

Langeveld K (2019) Phosphorus recovery into fertilizers and industrial products by ICL in Europe. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 235–252. https://doi.org/10.1007/978-981-10-8031-9_16

Lee Y-S, Lee S, Lim J-E, Moon H-B (2019) Occurrence and emission of phthalates and non-phthalate plasticizers in sludge from wastewater treatment plants in Korea. Sci Total Environ 692:354–360. https://doi.org/10.1016/j.scitotenv.2019.07.301

Lemming C, Bruun S, Jensen LS, Magid J (2017) Plant availability of phosphorus from dewatered sewage sludge, untreated incineration ashes, and other products recovered from a wastewater treatment system. J Plant Nutr Soil Sci 180:779–787. https://doi.org/10.1002/jpln.201700206

Leng L, Zhang J, Xu S, Xiong Q, Xu X, Li J, Huang H (2019) Meat & bone meal (MBM) incineration ash for phosphate removal from wastewater and afterward phosphorus recovery. J Clean Prod 238:117960. https://doi.org/10.1016/j.jclepro.2019.117960

López A, Rodríguez-Chueca J, Mosteo R, Gómez J, Ormad MP (2020) Microbiological quality of sewage sludge after digestion treatment: a pilot scale case of study. J Clean Prod 254:120101. https://doi.org/10.1016/j.jclepro.2020.120101

Lü H, Chen X-H, Mo C-H, Huang Y-H, He M-Y, Li Y-W, Feng N-X, Katsoyiannis A, Cai Q-Y (2021) Occurrence and dissipation mechanism of organic pollutants during the composting of sewage sludge: a critical review. Biores Technol 328:124847. https://doi.org/10.1016/j.biortech.2021.124847

Mackuľak T, Černanský S, Fehér M, Birošová L, Gál M (2019) Pharmaceuticals, drugs, and resistant microorganisms—environmental impact on population health. Curr Opin Environ Sci Health Environ Chem Sew Epidemiol 9:40–48. https://doi.org/10.1016/j.coesh.2019.04.002

MAFF (2012) Basic knowledge about sludge fertilizer (for the general public) [汚泥肥料に関する基礎知識 (一般向け) : 農林水産省 ] [WWW Document]. https://www.maff.go.jp/j/kanbo/joho/saigai/odei_qa.html. Accessed 13 Dec 22

MAFF (2022a) Response to radionuclide contamination in foods after the nuclear power plant accident: MAFF [WWW Document]. https://www.maff.go.jp/e/policies/food_safety/response.html. Accessed 13 Dec 22

MAFF (2022b) Handling points [取扱いのポイント: 農林水産省] [WWW Document]. https://www.maff.go.jp/j/syouan/nouan/kome/k_hiryo/caesium/point.html?fbclid=IwAR3x7jT6RdkMlYh7FA3YyRUnL20OaSCqTS8D2_srTna_E0iO0E0fm7hg1J8. Accessed 21 Dec 22

Mancinelli E, Baltrėnaitė E, Baltrėnas P, Paliulis D, Passerini G (2016) Trace metals in biochars from biodegradable by-products of industrial processes. Water Air Soil Pollut 227:198. https://doi.org/10.1007/s11270-016-2892-1

Mayer F, Bhandari R, Gäth SA (2021) Life cycle assessment of prospective sewage sludge treatment paths in Germany. J Environ Manag 290:112557. https://doi.org/10.1016/j.jenvman.2021.112557

McBride MB (2022) Long-term biosolids application on land: beneficial recycling of nutrients or eutrophication of agroecosystems? Soil Syst 6:9. https://doi.org/10.3390/soilsystems6010009

Mehr J, Jedelhauser M, Binder CR (2018) Transition of the Swiss phosphorus system towards a circular economy—part 1: current state and historical developments. Sustainability 10:1479. https://doi.org/10.3390/su10051479

Meng X, Huang Q, Xu J, Gao H, Yan J (2019) A review of phosphorus recovery from different thermal treatment products of sewage sludge. Waste Dispos Sustain Energy 1:99–115. https://doi.org/10.1007/s42768-019-00007-x

Mercl F, Košnář Z, Najmanová J, Hanzlíček T, Száková J, Tlustoš P (2018) Evaluation of mineral nutrient and trace element concentrations in anaerobically stabilized sewage sludge. Waste Forum 1:78–82. https://www.scopus.com/record/display.uri?eid=2-s2.0-85044577907&origin=resultslist&sort=plf-f&src=s&sid=cc10cb45ef9b21b923e5c2a27388076c&sot=b&sdt=b&s=TITLE-ABSKEY%28Evaluation+of+mineral+nutrient+and+trace+element+concentrations+in+anaerobically+stabilized+sewage+sludge%29&sl=120&sessionSearchId=cc10cb45ef9b21b923e5c2a2738807

Mininni G, Mauro E, Piccioli B, Colarullo G, Brandolini F, Giacomelli P (2019) Production and characteristics of sewage sludge in Italy. Water Sci Technol 79:619–626. https://doi.org/10.2166/wst.2019.064

MLIT (2022) Sewage: public-private study group for expanding fertilizer use of sewage sludge resources-Ministry of Land, Infrastructure, Transport and Tourism[下水汚泥資源の肥料利用の拡大に向けた官民検討会] [WWW Document]. https://www.mlit.go.jp/mizukokudo/sewerage/mizukokudo_sewerage_tk_000784.html. Accessed 24 Jan 23

Mochiyama T (2019) Industrial-scale manufacturing of phosphoric acid using sewage sludge ash. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 133–142. https://doi.org/10.1007/978-981-10-8031-9_7

Morf DL (2018) Verfahrenstechnische Marktanalyse für die Phosphorrückgewinnung aus dem Abwasserpfad [Process engineering market analysis for phosphorus recovery from the wastewater pathway. 100.

Morse GK, Brett SW, Guy JA, Lester JN (1998) Review: phosphorus removal and recovery technologies. Sci Total Environ 212:69–81. https://doi.org/10.1016/S0048-9697(97)00332-X

Moško J, Pohořelý M, Cajthaml T, Jeremiáš M, Robles-Aguilar AA, Skoblia S, Beňo Z, Innemanová P, Linhartová L, Michalíková K, Meers E (2021a) Effect of pyrolysis temperature on removal of organic pollutants present in anaerobically stabilized sewage sludge. Chemosphere 265:129082. https://doi.org/10.1016/j.chemosphere.2020.129082

Moško J, Pohořelý M, Skoblia S, Fajgar R, Straka P, Soukup K, Beňo Z, Farták J, Bičáková O, Jeremiáš M, Šyc M, Meers E (2021b) Structural and chemical changes of sludge derived pyrolysis char prepared under different process temperatures. J Anal Appl Pyrol 156:23. https://doi.org/10.1016/j.jaap.2021.105085

Munasinghe-Arachchige SP, Cooke P, Nirmalakhandan N (2020) Recovery of nitrogen-fertilizer from centrate of anaerobically digested sewage sludge via gas-permeable membranes. J Water Process Eng 38:101630. https://doi.org/10.1016/j.jwpe.2020.101630

Munoz G, Michaud AM, Liu M, Vo Duy S, Montenach D, Resseguier C, Watteau F, Sappin-Didier V, Feder F, Morvan T, Houot S, Desrosiers M, Liu J, Sauvé S (2022) Target and nontarget screening of PFAS in biosolids, composts, and other organic waste products for land application in France. Environ Sci Technol 56:6056–6068. https://doi.org/10.1021/acs.est.1c03697

Nakagawa H, Ohta J (2019) Phosphorus recovery from sewage sludge ash: a case study in Gifu, Japan. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 149–155. https://doi.org/10.1007/978-981-10-8031-9_9

Nättorp A, Remmen K, Remy C (2017) Cost assessment of different routes for phosphorus recovery from wastewater using data from pilot and production plants. Water Sci Technol 76:413–424. https://doi.org/10.2166/wst.2017.212

Nättorp A, Kabbe C, Matsubae K, Ohtake H (2019) Development of phosphorus recycling in Europe and Japan. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 3–27. https://doi.org/10.1007/978-981-10-8031-9_1

Nikolopoulou V, Ajibola AS, Aalizadeh R, Thomaidis NS (2023) Wide-scope target and suspect screening of emerging contaminants in sewage sludge from Nigerian WWTPs by UPLC-qToF-MS. Sci Total Environ 857:159529. https://doi.org/10.1016/j.scitotenv.2022.159529

Regulation No. 273/2021 Coll. on details of waste management [Vyhláška č. 273/2021 Sb. o podrobnostech nakládání s odpady] (consolidated version 01 January 2023), 2023

Nwoba EG, Moheimani NR (2022) Microalgae-based circular economy approach to upcycle fire extinguisher powder waste. Resour Conserv Recycl 180:106210. https://doi.org/10.1016/j.resconrec.2022.106210

Ohtake H, Tsuneda S (2018) Phosphorus recovery and recycling. Phosphorus Recovery Recycl. https://doi.org/10.1007/978-981-10-8031-9

Ooi TY, Yong EL, Din MFM, Rezania S, Aminudin E, Chelliapan S, Abdul Rahman A, Park J (2018) Optimization of aluminium recovery from water treatment sludge using Response Surface Methodology. J Environ Manag 228:13–19. https://doi.org/10.1016/j.jenvman.2018.09.008

Ottosen LM, Thornberg D, Cohen Y, Stiernström S (2022) Utilization of acid-washed sewage sludge ash as sand or cement replacement in concrete. Resour Conserv Recycl 176:105943. https://doi.org/10.1016/j.resconrec.2021.105943

Pradel M (2019) Survey data of sewage sludge treatment and disposal routes originated from activated sludge water treatment in France. Data Brief 26:104541. https://doi.org/10.1016/j.dib.2019.104541

Przydatek G, Wota AK (2020) Analysis of the comprehensive management of sewage sludge in Poland. J Mater Cycles Waste Manag 22:80–88. https://doi.org/10.1007/s10163-019-00937-y

Puijenbroek PJTM, Beusen AHW, Bouwman AF (2019) Global nitrogen and phosphorus in urban waste water based on the Shared Socio-economic pathways. J Environ Manag 231:446–456. https://doi.org/10.1016/j.jenvman.2018.10.048

Regulation (EC) No 767/2009 of the European Parliament and of the Council of 13 July 2009 on the placing on the market and use of feed, amending European Parliament and Council Regulation (EC) No 1831/2003 and repealing Council Directive 79/373/EEC, Commission Directive 80/511/EEC, Council Directives 82/471/EEC, 83/228/EEC, 93/74/EEC, 93/113/EC and 96/25/EC and Commission Decision 2004/217/EC (consolidated version 6.12.2018), 2018

Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No 1774/2002 (Animal by-products Regulation) (consolidated version 25 June 2019), 2019

Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 2003/2003 (consolidated version: 03 October 2022), 2022

Regulation No. 474/2000 Coll. of the Ministry of Agriculture on the specification of requirements for fertilisers [Vyhláška Ministerstva zemědělství č. 474/2000 Sb., o stanovení požadavků na hnojiva] (consolidated version 01 November 2021), 2021

Romanos D, Nemer N, Khairallah Y, Abi Saab MT (2019) Assessing the quality of sewage sludge as an agricultural soil amendment in Mediterranean habitats. Int J Recycl Org Waste Agricult 8:377–383. https://doi.org/10.1007/s40093-019-00310-x

Rosiek K (2020) Directions and challenges in the management of municipal sewage sludge in poland in the context of the circular economy. Sustainability 12:3686. https://doi.org/10.3390/su12093686

Santos AF, Almeida PV, Alvarenga P, Gando-Ferreira LM, Quina MJ (2021) From wastewater to fertilizer products: alternative paths to mitigate phosphorus demand in European countries. Chemosphere 284:131258. https://doi.org/10.1016/j.chemosphere.2021.131258

Šauer P, Švecová H, Grabicová K, Gönül Aydın F, Mackuľak T, Kodeš V, Blytt LD, Henninge LB, Grabic R, Kocour Kroupová H (2021) Bisphenols emerging in Norwegian and Czech aquatic environments show transthyretin binding potency and other less-studied endocrine-disrupting activities. Sci Total Environ 751:141801. https://doi.org/10.1016/j.scitotenv.2020.141801

Schinkel L, Lara-Martín PA, Giger W, Hollender J, Berg M (2022) Synthetic surfactants in Swiss sewage sludges: Analytical challenges, concentrations and per capita loads. Sci Total Environ 808:151361. https://doi.org/10.1016/j.scitotenv.2021.151361

Schipper W (2019) Success factors for implementing phosphorus recycling technologies. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 101–130. https://doi.org/10.1007/978-981-10-8031-9_6

Schnell M, Horst T, Quicker P (2020) Thermal treatment of sewage sludge in Germany: a review. J Environ Manag 263:110367. https://doi.org/10.1016/j.jenvman.2020.110367

Semerád J, Hatasová N, Grasserová A, Černá T, Filipová A, Hanč A, Innemanová P, Pivokonský M, Cajthaml T (2020) Screening for 32 per- and polyfluoroalkyl substances (PFAS) including GenX in sludges from 43 WWTPs located in the Czech Republic - Evaluation of potential accumulation in vegetables after application of biosolids. Chemosphere 261:128018. https://doi.org/10.1016/j.chemosphere.2020.128018

Sichler TC, Adam C, Montag D, Barjenbruch M (2022) Future nutrient recovery from sewage sludge regarding three different scenarios—German case study. J Clean Prod 333:130130. https://doi.org/10.1016/j.jclepro.2021.130130

Silva S, Rodrigues JA, Coelho MR, Martins A, Cardoso E, Cardoso VV, Benoliel MJ, Almeida CMM (2021) Occurrence of pharmaceutical active compounds in sewage sludge from two urban wastewater treatment plants and their potential behaviour in agricultural soils. Environ Sci Water Res Technol 7:969–982. https://doi.org/10.1039/D1EW00132A

Smol M, Adam C, Anton Kugler S (2020a) Inventory of Polish municipal sewage sludge ash (SSA)—mass flows, chemical composition, and phosphorus recovery potential. Waste Manag 116:31–39. https://doi.org/10.1016/j.wasman.2020.07.042

Smol M, Adam C, Kugler SA (2020b) Thermochemical treatment of sewage sludge ash (SSA)—potential and perspective in Poland. Energies 13:5461. https://doi.org/10.3390/en13205461

Sonoda K (2019) Alkaline leaching of phosphate from sewage sludge ash. In: Ohtake H, Tsuneda S (eds) Phosphorus recovery and recycling. Springer, Singapore, pp 143–148. https://doi.org/10.1007/978-981-10-8031-9_8

Spörri A, O’Connor I, Hermann L, Hermann R (2021) Technologien zur Phosphor-Rückgewinnung [Phosphorus recovery technologies]

Sun S-J, Zhao Z-B, Li B, Ma L-X, Fu D-L, Sun X-Z, Thapa S, Shen J-M, Qi H, Wu Y-N (2019) Occurrence, composition profiles and risk assessment of polycyclic aromatic hydrocarbons in municipal sewage sludge in China. Environ Pollut 245:764–770. https://doi.org/10.1016/j.envpol.2018.11.067

Sundha P, Basak N, Rai AK, Chandra P, Bedwal S, Yadav G, Yadav RK, Sharma PC (2022) Characterization and ecotoxicological risk assessment of sewage sludge from industrial and non-industrial cities. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-21648-2

Swain A, Singh SK, Mohapatra KK, Patra A (2021) Sewage sludge amendment affects spinach yield, heavy metal bioaccumulation, and soil pollution indexes. Arab J Geosci 14:717. https://doi.org/10.1007/s12517-021-07078-3

Tang N, Liu X, Xing W (2020) Microplastics in wastewater treatment plants of Wuhan, Central China: abundance, removal, and potential source in household wastewater. Sci Total Environ 745:141026. https://doi.org/10.1016/j.scitotenv.2020.141026

Tomczyk B, Siatecka A, Jędruchniewicz K, Sochacka A, Bogusz A, Oleszczuk P (2020) Polycyclic aromatic hydrocarbons (PAHs) persistence, bioavailability and toxicity in sewage sludge- or sewage sludge-derived biochar-amended soil. Sci Total Environ 747:141123. https://doi.org/10.1016/j.scitotenv.2020.141123

Tytła M (2019) Assessment of heavy metal pollution and potential ecological risk in sewage sludge from municipal wastewater treatment plant located in the most industrialized region in Poland—case study. Int J Environ Res Public Health 16:2430. https://doi.org/10.3390/ijerph16132430

Uogintė I, Pleskytė S, Pauraitė J, Lujanienė G (2022) Seasonal variation and complex analysis of microplastic distribution in different WWTP treatment stages in Lithuania. Environ Monit Assess 194:829. https://doi.org/10.1007/s10661-022-10478-x

US EPA, O., 2022. Basic Information about Biosolids [WWW Document]. https://www.epa.gov/biosolids/basic-information-about-biosolids. Accessed 1 Nov 22

Vambol V, Kowalczyk-Juśko A, Jóźwiakowski K, Mazur A, Vambol S, Khan NA (2022) Investigation in techniques for using sewage sludge as an energy feedstock: Poland’s experience. Ecol Quest. https://doi.org/10.12775/EQ.2023.007

van den Berg P, Huerta-Lwanga E, Corradini F, Geissen V (2020) Sewage sludge application as a vehicle for microplastics in eastern Spanish agricultural soils. Environ Pollut 261:114198. https://doi.org/10.1016/j.envpol.2020.114198

Wang X, Jin P, Lu H, Wang X (2014) A study on the impact of sludge water on biological phosphorus removal process of the municipal wastewater treatment plant and its treatment process. Desalin Water Treat 52:5037–5043. https://doi.org/10.1080/19443994.2013.874134