Abstract

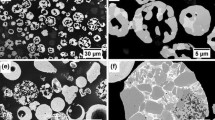

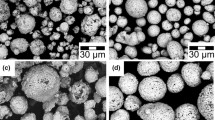

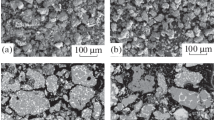

Three commercially available chromium carbide-based powders with different kinds of matrix (Cr3C2-25%NiCr; Cr3C2-25%CoNiCrAlY and Cr3C2-50%NiCrMoNb) were deposited by an HVOF JP-5000 spraying gun, evaluated and compared. The influence of heat treatment on the microstructure and properties, as well as the oxidation resistance in a hot steam environment (p = 24 MPa; T = 609 °C), was evaluated by SEM and XRD with respect to their potential application in the steam power industry. The sliding wear resistance measured at room and elevated (T = 600 °C) temperatures according to ASTM G-133. For all three kinds of chromium carbide-based coatings, the precipitation of secondary carbides from the supersaturated matrix was observed during the heat treatment. For Cr3C2-25%NiCr coating annealed in hot steam environment as well as for Cr3C2-25%CoNiCrAlY coating in both environments, the inner carbide oxidation was recorded. The sliding wear resistance was found equal at room temperature, regardless of the matrix composition and content, while at elevated temperatures, the higher wear was measured, varying in dependence on the matrix composition and content. The chromium carbide-based coating with modified matrix composition Cr3C2-50%NiCrMoNb is suitable to replace the Cr3C2-25%NiCr coating in a hot steam environment to eliminate the risk of failure caused by inner carbide oxidation.

Similar content being viewed by others

References

Š. Houdková, F. Zahálka, M. Kašparová, and L.M. Berger, Comparative Study of Thermally Sprayed Coatings Under Different Types of Wear Conditions for Hard Chromium Replacement, Tribol. Lett., 2011, 43(2), p 139-154

L.M. Berger, Application of Hardmetals as Thermal Spray Coatings, Int. J. Refract. Met. Hard Mater., 2015, 49(1), p 350-364

I. Hussainova, J. Pirso, M. Antonov, K. Juhani, and S. Letunovitš, Erosion and Abrasion of Chromium Carbide Based Cermets Produced by Different Methods, Wear, 2007, 263(7-12), p 905-911

J.M. Guilemany, J. Nutting, and N. Llorcalsern, Microstructural Examination of HVOF Chromium Carbide Coatings for High-Temperature Applications, J. Therm. Spray Technol., 1996, 5(4), p 483-489

G. Bolelli, L.M. Berger, T. Börner, H. Koivuluoto, V. Matikainen, L. Lusvarghi, C. Lyphout, N. Markocsan, P. Nylén, P. Sassatelli, R. Trache, and P. Vuoristo, Sliding and Abrasive wear Behaviour of HVOF- and HVAF-Sprayed Cr3C2-NiCr hardmetal coatings, Wear, 2016, 358-359, p 32-50

N. Espallargas, J. Berget, J.M. Guilemany, A.V. Benedetti, and P.H. Suegama, Cr3C2-NiCr and WC-Ni Thermal Spray Coatings as Alternatives to Hard Chromium for Erosion-Corrosion Resistance, Surf. Coatings Technol., 2008, 202(8), p 1405-1417

J.M. Guilemany, C. Lorenzana, J. Delgado, J. Sanchez, and C. Martı, Role of Heat Treatments in the Improvement of the Sliding Wear Properties of Cr3C2—NiCr Coatings, Surf. Coat. Technol., 2002, 157, p 207-213

S.S. Chatha, H.S. Sidhu, and B.S. Sidhu, The effects of post-treatment on the hot corrosion behavior of the HVOF-sprayed Cr3C2-NiCr coating, Surf. Coat. Technol., 2012, 206(19-20), p 4212-4224

L. Janka, J. Norpoth, R. Trache, and L.M. Berger, Influence of Heat Treatment on the Abrasive Wear Resistance of a Cr3C2-NiCr Coating Deposited by an Ethene-Fuelled HVOF Spray Process, Surf. Coat. Technol., 2016, 291, p 444-451

S. Matthews, M. Hyland, and B. James, Microhardness Variation in Relation to Carbide Development in Heat Treated Cr3C2-NiCr Thermal Spray Coatings, Acta Mater., 2003, 51(14), p 4267-4277

S. Matthews, M. Hyland, and B. James, Long-Term Carbide Development in High-Velocity Oxygen Fuel/High-Velocity Air Fuel Cr3C2-NiCr Coatings Heat Treated at 900 °C, J. Therm. Spray Technol., 2004, 13(4), p 526-536

S.J. Matthews, B.J. James, and M.M. Hyland, Microstructural Influence on Erosion Behaviour of Thermal Spray Coatings, Mater. Charact., 2007, 58(1), p 59-64

S. Matthews, B. James, and M. Hyland, Erosion of Oxide Scales Formed on Cr3C2-NiCr Thermal Spray Coatings, Corros. Sci., 2008, 50(11), p 3087-3094

S. Matthews, B. James, and M. Hyland, The Role of Microstructure in the Mechanism of High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: part 1—As-Sprayed Coatings, Surf. Coat. Technol., 2009, 203(8), p 1086-1093

S. Matthews, B. James, and M. Hyland, The Role of Microstructure in the Mechanism of High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: part 2—Heat Treated Coatings, Surf. Coat. Technol., 2009, 203(8), p 1094-1100

S. Matthews, B. James, and M. Hyland, High Temperature Erosion of Cr3C2-NiCr Thermal Spray Coatings—the Role of Phase Microstructure, Surf. Coat. Technol., 2009, 203(9), p 1144-1153

S. Matthews, B. James, and M. Hyland, High Temperature Erosion-Oxidation of Cr3C2-NiCr Thermal Spray Coatings Under Simulated Turbine Conditions, Corros. Sci., 2013, 70, p 203-211

S. Matthews, Development of High Carbide Dissolution/Low Carbon Loss Cr3C2-NiCr Coatings by Shrouded Plasma Spraying, Surf. Coat. Technol., 2014, 258, p 886-900

S. Matthews and L.M. Berger, Long-Term Compositional/Microstructural Development of Cr3C2-NiCr Coatings at 500, 700 and 900 °C, Int. J. Refract. Met. Hard Mater., 2016, 59, p 1-18

D. Poirier, J. Legoux, and R.S. Lima, Engineering HVOF-sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance, J. Therm. Spray Technol., 2013, 22, p 280-289

G. Bolelli, B. Bonferroni, J. Laurila, L. Lusvarghi, A. Milanti, K. Niemi, and P. Vuoristo, Micromechanical Properties and Sliding Wear Behaviour of HVOF-Sprayed Fe-Based Alloy Coatings, Wear, 2012, 276-277, p 29-47

V. Matikainen, G. Bolelli, H. Koivuluoto, L. Lusvarghi, and P. Vuoristo, Sliding Wear Behaviour of Thermally Sprayed Cr3C2-Based Coatings, Wear 2017. doi:10.1016/j.wear.2017.04.001.

L.M. Berger, M. Woydt, and S. Saaro, Comparison of Self-Mated Hardmetal Coatings Under Dry Sliding Conditions up to 600 °C, Wear, 2009, 266(3-4), p 406-416

J.G. Smeggil, The Oxidation Behaviour of an Aligned Co-TaC Eutectic Alloy, Oxid. Met., 1975, 9, p 225-257

F.H. Scott, G.C. Wood, and J.G. Fountain, High Temperature Oxidation of Directionally Solidified Ni-Al-Cr3C2 Eutectic, Oxid. Met., 1980, 14, p 31-45

S.S. Chatha, H.S. Sidhu, and B.S. Sidhu, High Temperature Hot Corrosion Behaviour of NiCr and Cr3C2-NiCr Coatings on T91 Boiler Steel in an Aggressive Environment at 750 °C, Surf. Coat. Technol., 2012, 206(19-20), p 3839-3850

Š. Houdková and R. Medlín, Analysis of Damage of Thermal Spray Coating Cr3C2-25%NiCr, Technical Report No. NTC–VYZ–12–049, New Technology Research Centre, University of West Bohemia, Plzeň, Czech Republic, November 2012 (in Czech).

L. Vernhes, D.A. Lee, D. Poirier, D. Li, and J.E. Klemberg-Sapieha, HVOF Coating Case Study for Power Plant Process Control Ball Valve Application, J. Therm. Spray Technol., 2013, 22(7), p 1184-1192

J.A. Picas, M. Punset, S. Menargues, E. Martín, and M.T. Baile, Microstructural and Tribological Studies of as-Sprayed and Heat-Treated HVOF Cr3C2-CoNiCrAlY Coatings with a CoNiCrAlY Bond Coat, Surf. Coat. Technol., 2015, 268, p 317-324

V. Matikainen, H. Koivuluoto, and P. Vuoristo, Microstructural Characteristics of Different Cr3C2 Coating Compositions Sprayed with HVOF and HVAF Processes Surface Modification Technologies XXVIII, ed. T.S.Sudharsan, P. Vuoristo, H. Koivuluoto, June 16-18, 2014, (Tampere, Finland), Valardocs, 2015, p 77-87.

Š. Houdková, J. Černý, Z. Pala, and P. Haušild, High Temperature Resistance of Selected HVOF Coatings, Key Eng. Mater., 2015, 662, p 111-114

H.M. Rietveld, A Profile Refinement Method for Nuclear and Magnetic Structures, J. Appl. Crystallogr., 1969, 2(2), p 65-71

R.W. Cheary and A. Coelho, A Fundamental Parameters Approach to X-ray Line-Profile Fitting, J. Appl. Crystallogr., 1992, 25(2), p 109-121

V. Matikainen, G. Bolelli, H. Koivuluoto, M. Honkanen, M. Vippola, L. Lusvarghi, and P. Vuoristo, A Study of Cr3C2-Based HVOF and HVAF-Sprayed Coatings: Microstructure and Carbide Retention, J. Therm. Spray Technol., 2017, 26, p 1239-1256

V. Shankar, K.B.S. Rao, and S.L. Mannan, Microstructure and Mechanical Properties of Inconel 625 Superalloy, J. Nucl. Mater., 2001, 288(2–3), p 222-232

Acknowledgment

The paper has originated in the framework of the solution of the Technology Agency of the Czech Republic Project Number TE01020068.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Houdková, Š., Česánek, Z., Smazalová, E. et al. The High-Temperature Wear and Oxidation Behavior of CrC-Based HVOF Coatings. J Therm Spray Tech 27, 179–195 (2018). https://doi.org/10.1007/s11666-017-0637-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0637-3