Abstract

The properties of natural hydraulic binders are directly influenced by the composition of the raw materials used in their production. Depending on the specific composition and conditions in the kiln during burning, the process results in the transformation of the natural raw material and the formation of new phases based on chemical interactions between neighbouring mineral components (solid–state ion migration). A series of laboratory experiments was performed in order to compare the characteristics of various limestones with their properties, phase composition and phase-to-phase relationships after burning. The main objective was to thoroughly understand the relationship between the composition of the raw material and the characteristics of the burnt product. A set of 21 limestone samples were first characterised in terms of raw materials (including their chemical composition), and then individually burnt in an electrical furnace to obtain calcined products. Optical microscopy, SEM–EDS, and XRD-QPA were used to assess the micro-structural character of the material before and after calcination, identifying the relationships between the character and amount of the non-carbonate impurities, the size and character of the carbonate matrix, and the constituted phases. The results show that the chemical composition, expressed as the cementation index, can be used to predict the hydraulicity of calcined limes. However, for this to be reliably applied to an unknown limestone, an understanding of the petrographic characteristics is necessary. The paper demonstrates several different types of phase to phase relationships before and after calcination. It also points out the relation between the micritic and sparitic character of raw materials, and the hydraulicity of burnt products.

Similar content being viewed by others

References

Kozłowski R, Hughes D, Weber J (2010) Roman Cements: key materials of the built heritage of the 19th century. In: Dan MB, Přikryl R, Török Á (eds) materials, technologies and practice in historic heritage structures. Springer, Dordrecht. https://doi.org/10.1007/978-90-481-2684-214

Silva BA, Ferreira Pinto AP, Gomes A (2015) Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr Build Mater 94:346–360. https://doi.org/10.1016/j.conbuildmat.2015.06.058

Maravelaki-Kalaitzaki P, Bakolas A, Karatasios I, Kilikoglou V (2005) Hydraulic lime mortars for the restoration of historic masonry in Crete. Cem Concr Res 35(8):1577–1586. https://doi.org/10.1016/j.cemconres.2004.09.001

Hughes DC, Jaglin D, Kozłowski R, Mucha D (2009) Roman cements – belite cements calcined at low temperature. Cem Concr Res 39:77–89. https://doi.org/10.1016/j.cemconres.2008.11.010

Blezard RG (1998) The history of calcareous cements. In: Hewlett PC (ed) Lea’s chemistry of cement and concrete, 4th edn. Elsevier, Oxford, pp 1–23

Moropoulou A, Bakolas A, Anagnostopoulou S (2005) Composite materials in ancient structures. Cement Concr Compos 27(2):295–300. https://doi.org/10.1016/j.cemconcomp.2004.02.018

Weber J, Gadermayr N, Kozłowski R, Mucha D, Hughes D, Jaglin D, Schwarz W (2007) Microstructure and mineral composition of Roman cements produced at defined calcination conditions. Mater Character 58:1217–1228. https://doi.org/10.1016/j.matchar.2007.04.025

Giavarini C, Ferretti AS, Santarelli ML (2006) Mechanical characteristics of Roman “opus caementicium.” In: Kourkoulis SK (ed) Fracture and failure of natural building stones. Springer, Berlin, pp 107–120

Moropoulou A, Polikreti K (2009) Principal component analysis in monument conservation: three application examples. J Cult Herit 10(1):73–81. https://doi.org/10.1016/j.culher.2008.03.007

Přikryl R, Weishauptová Z, Novotná M, Přikrylová J, Šťastná A (2011) Physical and mechanical properties of the repaired sandstone ashlars in the facing masonry of the Charles Bridge in Prague (Czech Republic) and an analytical study for the causes of its rapid decay. Environ Earth Sci 63(7–8):1623–1639

Bianco N, Calia A, De Notarpietro G, Negro P (2013) Laboratory assessment of the performance of new hydraulic mortars for restoration. Pro Chem 8:20–27

Moropoulou A, Bakolas A, Moundoulas P, Aggelakopoulou E, Anagnostopoulou S (2013) Optimization of compatible restoration mortars for the earthquake protection of Hagia Sophia. J Cult Herit 14(3):147–152. https://doi.org/10.1016/j.culher.2013.01.008

Henry A, Stewart J (2012) Practical building conservation. Mortars, renders & plasters. Ashgate Publishing, 643 pp. ISBN: 978-0-7546-4559-7

Douglas-Jones R, Hughes JJ, Jones S, Yarrowd T (2016) Science, value and material decay in the conservation of historic environments. J Cult Herit 21:823–833. https://doi.org/10.1016/j.culher.2016.03.007

Hughes DC, Sugden DB, Jaglin D, Mucha D (2008) Calcination of Roman cement: a pilot study using cement-stones from Whitby. Constr Build Mater 22:1446–1455. https://doi.org/10.1016/j.conbuildmat.2007.04.003

Callebaut K, Elsen J, Van Balen K, Viaene W (2001) Nineteenth century hydraulic restoration mortars in the Saint Michael’s church (Leuven, Belgium) Natural hydraulic lime or cement? Cem Concr Res 31:397–403. https://doi.org/10.1016/S0008-8846(00)00499-3

Mertens G, Madau P, Durinck D, Blanpain B, Elsen J (2007) Quantitative mineralogical analysis of hydraulic limes by X-ray diffraction. Cem Concr Res 37(11):1524–1530. https://doi.org/10.1016/j.cemconres.2007.08.002

Taylor HFW (1997) Cement chemistry, 2nd edn. Thomas Telford Publishing, London

Herfort D, Macphee DE (2019) Components in portland cement clinker and their phase relationships, Editor(s): Peter C. Hewlett, Martin Liska, Lea's chemistry of cement and concrete (Fifth Edition), Butterworth-Heinemann, pp 57–86. https://doi.org/10.1016/B978-0-08-100773-0.00003-4

Válek J (2015) Lime technologies of historic buildings, Preparation of specialised lime binders for conservation of historic buildings, ÚTAM AV ČR, Praha, 97 pp. ISBN 978-80-86246-58-1

Juenger MCG, Winnefeld F, Provis JL, Ideker JH (2011) Advances in alternative cementitious binders. Cem Concr Res 41:1232–1243

Lanas J, Pérez Bernal JL, Bello MA, Alvarez Galindo JI (2004) Mechanical properties of natural hydraulic lime-based mortars. Cem Concr Res 34(12):2191–2201. https://doi.org/10.1016/j.cemconres.2004.02.005

Silva BA, Ferreira Pinto AP, Gomes A (2015) Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr Build Mater 94(30):346–360. https://doi.org/10.1016/j.conbuildmat.2015.06.058

Hill N, Holmes S, Mather D (1992) Lime and other alternative cements. Intermediate Technology Publications, London, https://doi.org/10.4236/msa.2011.21008.

Oates JAH (1998) Lime and limestone. Chemistry and technology, production and uses, 1st edn. Wiley-VCH, Weinheim

Elsen J, Mertens G, Snellings R (2011) Portland cement and other calcareous hydraulic binders: history, production and mineralogy. In: Christidis GE. (ed.) Advances in the characterization of industrial minerals. European mineralogical union notes in mineralogy, Vol. 9, European Mineralogical Union, London, pp 441–479. https://doi.org/10.1180/EMU-notes.9.11

Boynton RS (1980) Chemistry and technology of lime and limestone, 2nd edn. Wiley, New York

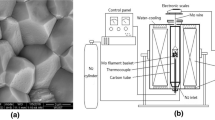

Válek J, van Halem E, Viani A, Pérez-Estébanez M, Ševčík R, Šašek P (2014) Determination of optimal burning temperature ranges for production of natural hydraulic limes. Constr Build Mater 66:771–780. https://doi.org/10.1016/j.conbuildmat.2014.06.015

Varas MJ, Alvarez de Buergo M, Fort R (2005) Natural cement as the precursor of Portland cement: methodology for its identification. Cem Concr Res 35(11):2055–2065. https://doi.org/10.1016/j.cemconres.2004.10.045

Eckel E (2005) Cements, limes and plasters, 3rd edn. Donhead Publishing, Dorset

Spalding, FP (1898) Hydraulic cement. Its properties, testing, and use. 1st ed., Wiley, New York.

Vicat LJ (1837) A practical and scientific treatise on calcareous mortars and cements, translated by Smith JT. John Weale, London

Schorcht F, Kourti I, Scalet BM, Roudier S, Delgado Sancho L (2013) Best available techniques (bat) reference document for the production of cement, lime and magnesium oxide. Industrial emissions directive 2010/75/EU integrated pollution prevention and control. JRC Reference Reports EUR 26129 EN, Joint Research Centre, Seville.

Rehan R, Nehdi M (2005) Carbon Dioxide emissions and climate change: policy implications for the cement industry. Environ Sci Policy 8(2):105–114. https://doi.org/10.1016/j.envsci.2004.12.006

Anand S, Vrat P, Dahiya RP (2006) Application of a system dynamics approach for assessment and mitigation of CO2 emissions from the cement industry. J Environ Manage 79(4):383–398. https://doi.org/10.1016/j.jenvman.2005.08.007

Cahn D, Greer W, Moir R (1997) Atmospheric CO2 and the U.S. Cement Industry. World Cem 28(8):64–68

Hossain MM, Karim MR, Hossain MK, Islam MN, Zain MFM (2015) Durability of mortar and concrete containing alkali-activated binder with pozzolans: a review. Constr Build Mater 93:95–109. https://doi.org/10.1016/j.conbuildmat.2015.05.094

Gartner EM (2004) Industrially interesting approaches to “low-CO2” cements. Cem Concr Res 34(9):1489–1498. https://doi.org/10.1016/j.cemconres.2004.01.021

Barcelo L, Kline J, Walenta G, Gartner E (2014) Cement and carbon emissions. Mater Struct 47(6):1055–1065. https://doi.org/10.1617/s11527-013-0114-5

Forster AM, Válek J, Hughes JJ, Pilcher N (2019) Lime binders for the repair of historic buildings: considerations for CO2 abatement. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.119802

Chlupáč I, Havlíček V, Kříž J, Kukal,Z, Štorch P (1998) Palaeozoic of the Barrandian (Cambrian to Devonian). Czech Geological Survey, Prague.

Chlupáč I, Brzobohatý R, Kovanda J, Stráník Z (2002) Geologická minulost České republiky. Academia, Prague (in Czech)

Kříž J (1992) Silurian field excursions: prague Basin (Barrandian), Bohemia. National Museum of Wales, Geological Service 13, Cardiff, 111 pages.

Chlupáč I (1999) Vycházky za geologickou minulostí Prahy a okolí. Academia, Prague (in Czech)

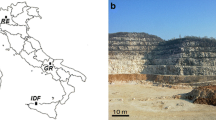

Kozlovcev P, Přikryl R (2015) Devonian micritic limestones used in the historic production of Prague hydraulic lime (‘pasta di Praga’): characterization of the raw material and experimental laboratory burning. Mater de Const 65(319): e060. https://doi.org/10.3989/mc.2015.06314

Kozlovcev P, Přikryl R (2016) Compositional characteristics and experimental burning of selected Lower Palaeozoic limestones from the Prague Basin (Barrandian area, Czech Republic) suitable for the production of natural hydraulic lime. Bull Eng Geol Env 76:21–37. https://doi.org/10.1007/s10064-016-0882-6

Kirschenbaum H (1983) The classical chemical analysis of silicate rocks – the old and the new. Geological survey bulletin, 1547, United States Government Printing Office, Washington. https://doi.org/10.3133/b1547

Rietveld HM (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2:65–71. https://doi.org/10.1107/S0021889869006558

Larson AC, Von Dreele RB (1999) Generalized structure analysis system. Los Alamos Nat. Lab. LAUR: New Mexico, pp 86–748.

Toby BH (2001) EXPGUI, a graphical user interface for GSAS. J Appl Crystallogr 34:210–213. https://doi.org/10.1107/S0021889801002242

Gualtieri AF (2000) Accuracy of XRPD QPA using the combined Rietveld–RIR method. J Appl Crystallo 33:267–78. https://doi.org/10.1107/S002188989901643X

Gualtieri AF, Viani TA, Montanari C (2005) Quantitative phase analysis of hydraulic limes using the Rietveld method. Cem Concr Res 36(2):401–406. https://doi.org/10.1016/j.cemconres.2007.08.002

Bish DL, Howard SA (1988) Quantitative phase analysis using the Rietveld method. J Appl Crystallogr 21:86–91. https://doi.org/10.1107/S0021889887009415

Folk RL (1962) Spectral subdivision of limestone types. In: Ham WE (ed.) Classification of carbonate rocks. American association of petroleum geologists, Memoir, vol. 1, pp. 62–84. https://doi.org/10.1007/978-90-481-2639-2_269

Dunham RJ (1962) Classification of carbonate rocks according to depositional texture. In: Ham WE (ed.) Classification of carbonate rocks. American Association of Petroleum Geologists, Memoir, vol. 1, pp. 108–121

Chlupáč I, Kukal Z (1986) Reflexion of possible global Devonian events in the Barrandian area, C.S.S.R. Lect Notes Earth Sci 8:171–179

BS EN 459–1 (2015) Building lime. Definitions, specifications and conformity criteria. British Standards Institution, Supersedes BS EN 459-1:2010, Confirmed March 2021, London, UK

Elsen J (2006) Micrsoscopy of historic mortars-a review. Cem Concr Res 36:10416–11424. https://doi.org/10.1016/j.cemconres.2005.12.006

Rodriguez-Navarro C, Elert K, Ševčík R (2016) Amorphous and crystalline calcium carbonate phases during carbonation of nanolimes: implications in heritage conservation. CrystEngComm 18(35):6594–6607. https://doi.org/10.1039/C6CE01202G

Válek J, Skužná O (2019) Performance assessment of custom-made renders replicating a historical original – a study into application influences. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.116822

Veiga MR, Fragata A, Velosa AL, Magalhães AC, Margalha G (2009) Lime-based mortars: viability for use as substitution renders in historical buildings. Int J Architect Herit 4:177–195. https://doi.org/10.1080/15583050902914678

Gulotta D, Goidanich S, Tedeschi C, Nijland T, Toniolo L (2013) Commercial NHL-containing mortars for the preservation of historical architecture. Part 1: compositional and mechanical characterisation. Constr Build Mater 38:31–42. https://doi.org/10.1016/j.conbuildmat.2012.08.029

Figueiredo CP, Ball RJ, Lawrence M (2016) Is BS EN 459–1:2015 fit for purpose in the context of conservation? J Build Limes Forum 23:46–52

Acknowledgements

The research was carried out with the support of the Czech Ministry of Culture, as a contribution to project DG20P02OVV028. Dr. Alberto Viani carried out the XRD-QPA, Petra Hauková carried out the wet chemical analysis, and Marek Eisler proofread the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kozlovcev, P., Válek, J. The micro-structural character of limestone and its influence on the formation of phases in calcined products: natural hydraulic limes and cements. Mater Struct 54, 217 (2021). https://doi.org/10.1617/s11527-021-01814-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-021-01814-7