Abstract

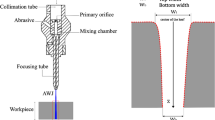

Erosion process of the Abrasive Water Jet (AWJ) machining on a rock material depends on various parameters. A brittle rock material is removed predominantly by the deformation wear. Abrasive grains can enhance the machining since their hardness and therefore material removal is better than work of pure water. However, to this day, determination of an optimal dosage of the abrasive matter entering into the mixing chamber was rather neglected. Based on the laws of conservations of momentum and energy combined with some empirical facts, it is possible to derive an equation for erosion of the material and subsequently another relation that provides estimation of the optimal mass flow rate of an abrasive matter. The main equation for erosion consists of six experimental coefficients, for an intensive AWJ only four, describing the effectivity of the water jet kw and abrasive jet ka impacting the material. It seems that the energy that is used for erosion is very small and the ideal dosage of the abrasive material is approximately Ṁa ≈ ṁw·(1 − 2kw/ka), where Ṁa and ṁw are the abrasive and water mass flow rates. Such an equation could be used for setting of AWJ machines. The economical optimum (eo) for cutting is proposed via the relation eo = E/Emax − R/Rmax, with the erosion E and its maximum value and the resistivity R and its maximum value.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- \( a\;\left( {\text{m}} \right) \) :

-

size of the cubic abrasive grain (length of the side)

- \( \Delta A\;\left( {{\text{m}}^{2} } \right) \) :

-

change of the surface area of the material

- \( b\;\left( {\text{m}} \right) \) :

-

interatomic distance in a crystal

- \( D\;\left( {\text{m}} \right) \) :

-

nozzle diameter

- \( D_{\text{f}} \;\left( {\text{m}} \right) \) :

-

focusing tube diameter

- \( e\;\left( {\text{Pa}} \right) \) :

-

young modulus of the material

- \( E\;\left( {{\text{kg}}/{\text{s}}} \right) \) :

-

erosion of the material (removed mass of material per time)

- \( E_{rel} \;\left( {{\text{kg}}/{\text{kg}}} \right) \) :

-

relative erosion of the material (removed mass of the material/mass of abrasives)

- \( f(\upalpha)\;\left( \text{ - } \right) \) :

-

function of the impact angle α, for brittle rock materials Eq. f (α) = [1 + sin(2α + 90°)]/2 is valid

- \( h\;\left( {\text{m}} \right) \) :

-

depth of cut into the material

- \( k_{i} \;\left( \text{ - } \right) \) :

-

dimensionless constant less or equal to 1

- \( k_{01, \, 02} \;\left( \text{ - } \right) \) :

-

positive coefficients

- \( k_{a} \;\left( \text{ - } \right) \) :

-

dimensionless impact effectivity of the abrasive particles

- \( k_{w} \;\left( \text{ - } \right) \) :

-

dimensionless impact effectivity of the water jet

- \( K\;\left( \text{ - } \right) \) :

-

K = aρm/(6γ)

- \( K_{1} \;\left( \text{ - } \right) \) :

-

unknown dimensionless coefficient

- \( m_{a} \;\left( {\text{kg}} \right) \) :

-

mass of the single abrasive grain

- \( \dot{m}_{\text{w}} \;\left( {{\text{kg}}/{\text{s}}} \right) \) :

-

mass flow rate of water exiting from the nozzle, general rule is ṁw = dmw/dt

- \( \dot{m}_{w0} \;\left( {{\text{kg}}/{\text{s}}} \right) \) :

-

minimal mass flow rate of water exiting from the nozzle capable to start material erosion

- \( \dot{M}_{\text{a}} \;\left( {kg/s} \right) \) :

-

mass flow rate of abrasive grains exiting from the mixing chamber

- \( \dot{M}_{{{\text{a}}0}} \;\left( {{\text{kg}}/{\text{s}}} \right) \) :

-

minimal mass flow rate of abrasive grains capable to start material erosion

- \( M_{m} \;\left( {\text{kg}} \right) \) :

-

mass of material grains

- \( \dot{M}_{m} \;\left( {{\text{kg}}/{\text{s}}} \right) \) :

-

mass flow rate of material grains

- \( N\;\left( \text{ - } \right) \) :

-

number of material grains

- \( N\;\left( \text{ - } \right) \) :

-

number of material grains per time unit

- \( P\;\left( {\text{Pa}} \right) \) :

-

pressure of water in the nozzle

- \( P_{0} \;\left( {\text{Pa}} \right) \) :

-

minimal pressure of the water jet capable to remove material

- \( q\;\left( \text{ - } \right) \) :

-

quality parameter of the surface

- \( \dot{Q}\;\left( W \right) \) :

-

rate of heat production by the AWJ, dQ/dt

- \( R\;\left( {{\text{kg}}/{\text{kg}}} \right) \) :

-

resistivity of the material (mass abrasive consumption/mass material wear)

- \( r_{m} \;\left( {\text{Pa}} \right) \) :

-

strength of the material

- \( t\;\left( {\text{s}} \right) \) :

-

time

- \( u\;\left( {{\text{m}}/{\text{s}}} \right) \) :

-

speed of movement of nozzle above material

- \( v_{w} \;\left( {{\text{m}}/{\text{s}}} \right) \) :

-

speed of the water jet exiting from the nozzle

- \( v\;\left( {{\text{m}}/{\text{s}}} \right) \) :

-

speed of the AWJ exiting from the mixing chamber

- \( \Delta V\;\left( {{\text{m}}^{3} } \right) \) :

-

element of volume in the material

- \( x\;\left( {\text{m}} \right) \) :

-

size of the cubic abrasive grain (length of the side)

- \( \gamma \;\left( {{\text{J}}/{\text{m}}^{2} } \right) \) :

-

surface energy of the material

- \( \mu \;\left( \text{ - } \right) \) :

-

discharge coefficient of the nozzle, μ ≈ 0.6

- \( \lambda_{i} \;\left( {{\text{m}}^{ - 1} } \right) \) :

-

positive coefficient of damping of the erosion

- \( \rho_{a} \;\left( {{\text{kg}}/{\text{m}}^{3} } \right) \) :

-

true density of abrasive grains

- \( \rho_{m} \;\left( {{\text{kg}}/{\text{m}}^{3} } \right) \) :

-

true density of material grains

References

Sodomka, L.: Eroze materiálu proudem částic. Jemná mechanika a optika, pp. 77–80 (1976)

Martinec, P., Hlaváček, P., Ruppenthalová, L., Sitek, L.: Properties and characteristics of recycled garnet abrasives for AWJ. In: Water Jet 2017, pp. 101–125. Ústav Geoniky AVČR, Ostrava (2017)

Summers, David A.: Waterjetting Technology. E & FN Spon, New York (1995)

Kovacevic, R., Hashish, M., Mohan, R., Ramulu, M., Kim, T.J., Geskin, E.S.: State of the Art of the Research and Development in Abrasive Waterjet Machining. Trans. ASME, 776–785 (1997)

Martinec, P., Foldyna, J., Sitek, L., Ščučka, J., Vašek, J.: Abrasives for AWJ Cutting. Academy of Science of the Czech Republic, Ostrava (2002)

Zeng, J., Kim, T.J.: Parameter prediction and cost analysis in abrasive waterjet cutting operations. In: 7th American Water Jet Conference, Seattle (1993)

Hlaváč, L.M., et al.: Comminution of material particles by water jets - influence of the inner shape of the mixing chamber. Int. J. Mineral Process. 95, 25–29 (2010)

Henning, A., Miles, P., Schubert, E.: Effect of particle fragmentation on performance of the abrasive waterjet. In: Water Jetting 2018. BHR Group, pp. 89–102 (2018)

Jandačka, P., Hlaváč, L.M., Mádr, V., Šancer, J., Staněk, F.: Measurement of specific fracture energy and surface tension of brittle materials in powder form. Int. J. Fract. 1(1), 103–110 (2009)

Jandačka, P., Mádr, V.: Fracture energy of abrasive materials. In: Klichová, D., Sitek, L. (eds.) Water Jet 2015. Institute of Geonics of the CAS, Velké Losiny (2015)

Jandačka, P., et al.: Fracture energy of selected brittle silicates. Ceramics - Silikáty 55, 355–361 (2011)

Griffith, A.A.: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. London Ser. A 221, 163–198 (1921)

Foldyna, J., Sitek, L., Švehla, B., Švehla, Š.: Utilization of ultrasound to enhance high-speed water jet effect. Ultrason. Sonochem. 11, 131–137 (2004)

Jandačka, P., Hlaváč, L., Uhlář, R., Mádr, V., Burkovič, J.: Regression model for depth of cut of water jet into rock materials, pp. 117–124. Transaction of the VŠB - Technical University of Ostrava, Mechanical Series (2009)

Acknowledgements

This work has been supported by:

1. the Project Institute of Clean Technologies for Mining and Utilisation of Raw Materials for Energy Use – Sustainability Program, Reg. No. LO1406 financed by the Ministry of Education, Youth, and Sports of the Czech Republic.

2. the Czech Science Foundation, project Reg. No. 18-250355.

3. the Grant Agency of the Slovak Republic, project Reg. No. 2/0142/19 and No. 1/0599/18.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Jandačka, P. et al. (2021). Optimal Abrasive Mass Flow Rate for Rock Erosion in AWJ Machining. In: Klichová, D., Sitek, L., Hloch, S., Valentinčič, J. (eds) Advances in Water Jetting. Water Jet 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-53491-2_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-53491-2_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-53490-5

Online ISBN: 978-3-030-53491-2

eBook Packages: EngineeringEngineering (R0)