Abstract

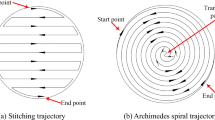

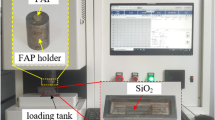

The paper compares the quality of machined surface of graphite and aluminium alloy by abrasive waterjet using the focusing tube with a diameter of d f1 = 0.5 mm and d f2 = 0.78 mm. The machining was carried out using the technology of rotating workpiece disintegration by abrasive waterjet. Abrasive tangential waterjet was used to carry out the experiment (water pressure P = 400 MPa). Workpieces were clamped in the rotating chucking appliance with rotation frequency n = 300 min−1. The change in focusing tube diameter caused the change in values of roughness parameters and also caused the change of resulting shape of workpieces. Values of roughness parameters were measured using the MicroProf FRT optic profilometer.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Sharma, V., Chattopadhyaya, S., Hloch, S.: Multi response optimization of process parameters based on Taguchi-Fuzzy model for coal cutting by water jet technology. Int. J. Adv. Manuf. Technol. 56, 1019–1025 (2011)

Hreha, P., Radvanská, A., Hloch, S., Peržel, V., Królczyk, G., Monková, K.: Determination of vibration frequency depending on abrasive mass flow rate during abrasive water jet cutting. Int. J. Adv. Manuf. Technol. 77, 763–774 (2015)

Hreha, P., Radvanska, A., Knapcíkova, L., Krolczyk, G.M., Legutko, S., Krolczyk, J., et al.: Roughness parameters calculation by means on-line vibration monitoring emerging from AWJ interaction with material. Metrol. Meas. Syst. XXII 2, 315–326 (2015)

Manu, R., Babu, N.R.: Influence of jet impact angle on part geometry in abrasive waterjet turning of aluminium alloys. Int. J. Mach. Mach. Mater. 3 (2008)

Cárach, J., Hloch, S., Hlaváček, P., Ščučka, J., Martinec, P., Petrů, J., et al.: Tangential turning of Incoloy alloy 925 using abrasive water jet technology. Int. J. Adv. Manuf. Technol. 82, 1747–1752 (2016)

Hloch, S., Hlaváček, J., Vasilko, K., Cárach, J., Samardžić, I., Kozak, D., et al.: Abrasive waterjet (AWJ) titanium tangential turning evaluation. Metalurgija 53, 537–540 (2014)

Sitek, L., Foldyna, J., Souček, K., Shaping of rock specimens for testing of uniaxial tensile strength by high speed abrasive water jet: first experience. In: Impact of Human Activity on the Geological Environment—Proceedings of the International Symposium of the International Society for Rock Mechanics, Eurock (2005)

Hlaváček, P., Cárach, J., Hloch, S., Vasilko, K., Klichová, D., Klich, J., et al.: Sandstone turning by abrasive waterjet. Rock Mech. Rock Eng. 48. ISSN 2489–93 (2015)

Hutyrova, Z., Scucka, J., Hloch, S., Hlavacek, P., Zelenak, M.: Turning of wood plastic composites by water jet and abrasive water jet. Int. J. Adv. Manuf. Technol. 84, 1615–1623 (2016)

Duplak, J., Hatala, M., Botko, F., Kormos, M.: Analysis of cutting tools durability importance in turning process of steel C60. In: Key Engineering Materials: Operation and Diagnostics of Machines and Production Systems Operational States 3, vol. 669, pp. 319–326 (2016)

Zhong, Z.W., Han, Z.Z.: Turning of glass with abrasive waterjet. Mater. Manuf. Process 17, 339–349 (2002)

Axinte, D.A., Stepanian, J.P., Kong, M.C., McGourlay, J.: Abrasive waterjet turning-An efficient method to profile and dress grinding wheels. Int. J. Mach. Tools Manuf. 49, 1–6 (2009)

Liu, D., Huang, C., Wang, J., Zhu, H., Yao, P., Liu, Z.: Modeling and optimization of operating parameters for abrasive waterjet turning alumina ceramics using response surface methodology combined with Box-Behnken design. Ceram Int. 40 (2014)

den Dunnen, S., Mulder, L., Kerkhoffs, G.M.M.J., Dankelman, J., Tuijthof, G.J.M.: Waterjet drilling in porcine bone: the effect of the nozzle diameter and bone architecture on the hole dimensions. J. Mech. Behav. Biomed. Mater. 27, 84–93 (2013)

Hloch, S., Valíček, J., Kozak, D.: Preliminary results of experimental cutting of porcine bones by abrasive waterjet. Tech. Vjesn. 18, 467–470 (2011)

Lissek, F., Kaufeld, M., Tegas, J., Hloch, S.: Online-monitoring for abrasive waterjet cutting of CFRP via acoustic emission: Evaluation of machining parameters and work piece quality due to burst analysis. Proc. Eng. 67–76 (2016)

Hreha, P., Hloch, S.: Potential use of vibration for metrology and detection of surface topography created by abrasive waterjet. Int. J. Surf. Sci. Eng. 7, 135–151 (2013)

Hreha, P., Radvanska, A., Carach, J., Lehocka, D., Monkova, K., Krolczyk, G., et al.: Monitoring of focusing tube wear during Abrasive WaterJet (AWJ) cutting of AISI 309. Metalurgija 53, 533–536 (2014)

Lehocka, D., Klich, J., Foldyna, J., Hloch, S., Krolczyk, J.B., Carach, J., et al.: Copper alloys disintegration using pulsating water jet. Measurement 82, 375–383 (2016)

Lebar, A., Junkar, M., Poredoš, A., Cvjeticanin, M.: Method for online quality monitoring of AWJ cutting by infrared thermography. CIRP J. Manuf. Sci. Technol. 2, 170–175 (2010)

Hashish, M., South, A.: Optimization factors in abrasive—waterjet machining. J. Eng. Ind. 1 (1991)

Dong, Y., Liu, W., Zhang, H., Zhang, H.: On-line recycling of abrasives in abrasive water jet cleaning. Proc. CIRP (2014)

Arola, D., Ramulu, M.: A study of Kerf characteristics in abrasive waterjet machining of graphite/epoxy composite. J. Eng. Mater. Technol. Trans. ASME 118, 256–265 (1996)

Acknowledgements

This work was supported by the Slovak Research and Development Agency under Contract No. APVV-207-12. Experiments were carried out with the support of the Institute of Clean Technologies for Mining and Utilization of Raw Materials for Energy Use—Sustainability Program, reg. no. LO1406 financed by Ministry of Education, Youth and Sports of the Czech Republic, and with support for the long-term conceptual development of the research institution RVO: 68145535.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Carach, J., Lehocka, D., Legutko, S., Hloch, S., Chattopadhyaya, S., Dixit, A.R. (2018). Surface Roughness of Graphite and Aluminium Alloy After Hydro-abrasive Machining. In: Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M. (eds) Advances in Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-68619-6_78

Download citation

DOI: https://doi.org/10.1007/978-3-319-68619-6_78

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68618-9

Online ISBN: 978-3-319-68619-6

eBook Packages: EngineeringEngineering (R0)