Abstract

Low deformational resistance of polymers can be effectively improved by reinforcement, mostly using rigid particles and fibers. In contrast, this work reveals lower tensile creep resistance of microfibrillar composites (MFC) based on high-density polyethylene (HDPE) reinforced with in-situ formed polyamide 66 (PA66) fibrils against original undrawn system containing spherical inclusions. This performance is quite different from that of other known composites containing e.g. glass fibers or spheres. Moreover, the incorporation of graphite nanoplatelets (GNP) partly eliminates this shortcoming in MFC but worsens performance of undrawn system reinforced with PA66 inclusions. The obtained results highlight so far unknown negative effect of relatively low-modulus viscoelastic fibers and GNP-modified parameters of interface on creep resistance of polymer-polymer composites.

Similar content being viewed by others

References

Meyers MA, Chawla KK (1999) Mechanical behavior of materials, Cambridge university press. p. 573

Schlag S, Rösch J, Friedrich C (1993) Creep measurements on “in situ” compatibilized polypropylene/polyamide-6 blends Polym Bull 30: 603

Hassanzadeh-Aghdam MK, Ansari R, Mahmoodi MJ, Darvizeh A (2018) Effect of nanoparticles aggregation on the creep behavior of polymer nanocomposite. Comp Sci Technol 162:93–100

Liu C-M, Ma F-F, Zhang Z-X, Yang J-H, Wong Y, Zhou Z-W (2017) Selective localization of organic montmorillonite in poly(L-lactide)/poly (ethylene vinyl acetate) blends and the resultant proprieties. Compos Pt B: Eng 123:1–9

Tang L, Li Y, Chen Y, Ji P, Wong H, Wong C, Huang Q (2018) Preparation and characterization of graphene reinforced PA6 fiber. J Appl Polym Sci 135:45834

Seyhan AT, Tuna A, Durukan O, Göncü Y, Turan S, Ay N (2018) Creep and recovery behaviors of chemically induced grafted low density polyethylene films containing silanized hexagonal boron nitride nanosheets. Mater Express 8:55–67

Suvorova YV, Alekseeva SI, Fronya MA, Viktorova IV (2013) Investigations of physical and mechanical proprieties of polymeric nanocomposites. Inorg Mater 49:1357–1368

Dai Z, Gao Y, Liu L, Pötschke P, Yang J, Zhang Z (2013) Creep-resistance behavior of MWCNT-polycarbonate melt spun nanocomposite fibers at elevated temperature. Polymer 54:3723–3729

Dorigato A, Pegoretti A, Kolařík J (2010) Nonlinear tensile creep of linear low density polyethylene/fumed silica nanocomposites time-strain superposition and creep prediction. Polym Compos 3:1947–1955

Li M, Li D, Wang LJ, Adhikari B (2015) Creep behavior of starch-based nanocomposite films with cellulose nanofibrils. Carbohydr Polym 117:957–963

Xu Y, Wu Q, Lei Y, Yao F (2010) Creep behavior of bagasse fiber reinforced polymer composites. Bioresour Technol 101:3280–3286

Mileiko ST (1970) Steady state creep of a composite material with short fibres. J Mater Sci 5:254–271

Bhattacharya SN, Gupta RK, Kamal MR (2008) Polymeric nanocomposites. Hanser Munich

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of Nano filler/natural Fiber filled polymer hybrid composites. Polymers 6:2247–2273

Suresha B, Ravi Kumar BN, Venkataramareddy M, Jayaraju T (2010) Role of micro/nano fillers on mechanical and tribological properties of polyamide66/polypropylene composites. Mater Des 31:1993–2000

Varela-Rizo H, Weisenberger M, Bortz DR, Martin-Gullon I (2010) Fracture toughness and creep performance of PMMA composites containing micro and nanosized carbon filaments. Comp Sci Technol 70:1189–1195

Friedrich K, Evstatiev M, Fakirov S, Evstatiev O, Ishii M, Harrass M (2005) Microfibrillar reinforced composites from PET/PP blends: processing, morphology and mechanical properties. Comp Sci Technol 65:107–116

Jayanarayan K, Thomas S, Joseph K (2008) Morphology, static and dynamic mechanical properties of in situ microfibrillar composites based on polypropylene/poly (ethylene terephthalate) blends. Compos A Appl Sci Manuf 39:164–175

Fakirov S, Bhattacharyya D, Lin RJT, Fuchs C, Friedrich K (2007) Contribution of coalescence to microfibril formation in polymer blends during cold drawing. J Macromol Sci Part B-Phys 46:183–193

Kelnar I, Fortelný I, Kaprálková L, Kratochvíl J, Nevoralová M (2016) Effect of layered silicates on fibril formation and properties of PCL/PLA microfibrillar composites. J Appl Polym Sci 133:43061

Lin RJT, Bhattacharyya D, Fakirov S (2010) Innovative manufacturing of carbon nanotube-loaded fibrillar polymer composites. Int J Mod Phys B 24:2459–2465

Yesil S, Bayram G (2013) Effect of carbon nanotube surface treatment on the morphology, electrical, and mechanical properties of the microfiber-reinforced polyethylene/poly (ethylene terephthalate)/carbon nanotubecomposites. J Appl Polym Sci 127:982–991

Kelnar I, Kaprálková L, Kratochvíl J, Kotek J, Kobera L, Rotrekl J, Hromádková J, Effect of nanofiller on the behaviour of a melt-drawn HDPE/PA6 microfibrillar composite. J Appl Polym Sci 132: 41868

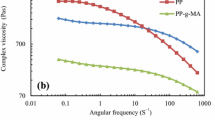

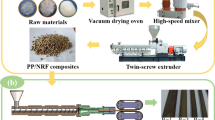

Kelnar I, Bal Ü, Zhigunov A, Kaprálková L, Fortelný I, Krejčíková S, Kredatusová J (2018) Complex effect of graphite nanoplatelets on performance of HDPE/PA66 microfibrillar composites. Compos Pt B: Eng 144:220–228

Kelnar I, Kratochvíl J, Kaprálková L, Padovec Z, Růžička M, Zhigunov A, Nevoralová M (2017) Antagonistic effects on mechanical properties of Microfibrillar composites with dual reinforcement: explanation by FEA model of soft Interface. J Appl Polym Sci 134:44712

Liu H, Yao F, Xu Y, Wu Q (2010) A novel wood flour-filled composite based on microfibrillar high-density polyethylene (HDPE)/Nylon-6 blends. Bioresour Technol 101:3295–3297

Kelnar I, Kratochvíl J, Kaprálková L, Zhigunov A, Nevoralová M (2017) Graphite nanoplatelets-modified PLA/PCL: effect of blend ratio and nanofiller localization on structure and properties. J Mech Behav Biomed Mater 71:271–278

Rajesh K, Crasta V, Rithin Kumar NB, Shetty G, Rekha PD (2019) Structural, optical, mechanical and dielectric properties of titanium dioxide doped PVA/PVP nanocomposite. J Polym Res 26:99

Kelnar I, Kratochvíl J, Fortelný I, Kaprálková L, Zhigunov A, Kotrisová M, Khunová V, Nevoralová M (2016) Influence of clay-nanofiller geometry on the structure and properties of poly (lactic acid)/thermoplastic polyurethane nanocomposites. RSC Adv 6:30755–30762

Zonder L, Mccarthy S, Rios F, Ophir A, Kenig S (2014) Viscosity ratio and interfacial tension as carbon nanotubes distributing factors in melt-mixed blends of polyamide 12 and high-density polyethylene. Adv Polym Technol 33:21427

Jeon HK, Feist BJ, Koh SB, Chang K, Macosko CW, Dion RP (2004) Reactively formed block and graft copolymers as compatibilizers for polyamide 66/PS blends. Polymer 45:197–206

Cheng C, Aravas N (1997) Creep of metal-matrix composites with elastic fibers—part I: continuous aligned fibers. Int J Sol Struct 34:4147–4171

Garoushi S, Kaleem M, Shinya A, Vallittu PK, Satterthwaite JD, Watts DC, Lassila LV (2012) Creep of experimental short fiber-reinforced composite resin. Dent Mater J 31:737–741

Almeida JH, Ornaghi HL, Lorandi NP, Bregolin BP, Amico SC (2018) Creep and interfacial behavior of carbon fiber reinforced epoxy filament wound laminates. Polym Compos 39:E2199–E2206

Li Y, Shen M, Chen W, Chiang C, Yip M (2012) Tensile creep study and mechanical properties of carbon fiber nano-composites. J Polym Res 19:9893–9900

Li J, Weng GJ (1996) Effect of a viscoelastic interphase on the creep and stress/strain behavior of fiber-reinforced polymer matrix composites. Compos Pt B: Eng 27:589–598

Kelnar I, Ujčič A, Kaprálková L, Krejčíková S, Zhigunov A, Novotný C, Padovec Z, Růžička M (2020) Creep resistance of HDPE/PA66 system: effect of PA66 phase geometry and graphite nanoplatelets addition. Polym Test 85:106452. https://doi.org/10.1016/j.polymertesting.2020.106452

Acknowledgements

This work was supported by Czech Science Foundation (Grant No 16-03194S and 19-06065S).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kelnar, I., Bal, Ü., Ujčič, A. et al. Creep behavior of HDPE/PA66 microfibrillar composites modified with graphite nanoplatelets. J Polym Res 27, 113 (2020). https://doi.org/10.1007/s10965-020-02093-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02093-6