Abstract

We report a high-brightness mid-IR diode-pumped laser based on 15 at.% Er:Y2O3 ceramics operated at room temperature. Up to 0.95 W of output power at 2725 nm was obtained with a 17.4% slope efficiency with respect to the absorbed pump power and with an M2 < 1.2. Furthermore, a maximum peak output power of 9 W was generated with pulsed pumping. Perspectives for further efficiency and power scaling are also considered.

Export citation and abstract BibTeX RIS

1. Introduction

Mid-IR laser sources emitting at wavelengths around 3 µm are attractive for applications including molecular spectroscopy [1], material processing [2], or laser surgery [3] due to the strong absorption by water and water vapor in this spectral region. Furthermore, they can be used for efficient optical pumping of longer-wavelength solid-state lasers and optical parametric generators. Direct generation with diode-pumped erbium lasers operating at 2.7–3.0 µm is the most straightforward approach to reach this wavelength range, using the 4I15/2 → 4I11/2 ≈ 0.98 µm pump transition and the 2.7 µm 4I11/2 → 4I13/2 laser transition. This lasing scheme leads to a high quantum defect of about 65%, imposing significant heat load on the gain medium and requiring good thermal conductivity of the laser material. Moreover, the lower laser manifold has a longer lifetime than the higher laser manifold, making the laser transition self-terminating and impeding continuous-wave (CW) operation [4]. It is possible to overcome this difficulty by co-doping the gain medium with another active ion, such as Pr3+ [5], employing a cascade lasing scheme [6], or by optimizing the doping concentration to fully utilize the beneficial 4I13/2 + 4I13/2 → 4I9/2 + 4I15/2 upconversion process. The complex energy level structure of the Er3+ ion also facilitates undesirable excited-state absorption (ESA) and limits the choice of optimum pump wavelength [7].

Cubic sesquioxides, and Y2O3 in particular, emerged as excellent host materials for erbium lasers, owing to their superior thermal conductivity [8], low phonon energy maximizing the upper-laser-level lifetime (4I11/2 lifetime is 2.4 ms [9]), and relatively low optimum doping concentration for depopulation of the lower laser manifold via upconversion [7, 10]. A high melting point of over 2400 °C makes the growth of sesquioxide monocrystals difficult, and thus the focus shifted to the manufacturing of polycrystalline ceramics, which requires much lower temperatures. Cryogenically-cooled Er:Y2O3 ceramics have been repeatedly shown to support efficient high-power CW operation up to 24 W [9, 11], since at low temperature the thermal conductivity of the gain medium is increased by an order of magnitude and its spectroscopic properties are also improved. However, watt-level CW mid-IR generation with Er:Y2O3 at room temperature was demonstrated only very recently [10, 12], as well as both active and passive Q-switched operation [12–14].

In this work we show the potential of Er:Y2O3 ceramics for high-efficiency room temperature CW operation and report on reaching watt-level output power in nearly diffraction-limited beams from ceramics with 15 at.% doping concentration. Such high doping is advantageous for power scaling of lasers using advanced geometries of the gain medium, e.g. in thin-disk lasers. The results shown here represent an improvement in power and efficiency over previous works concerned with highly doped Er:Y2O3 ceramics.

2. Laser setup and experimental details

The laser ceramics used in this experiment were 15 at.% Er3+-doped Y2O3 fabricated by the Konoshima Chemical Co. Ltd. The samples were 5 mm long with a clear aperture of 1 × 2 mm2, with both faces polished but uncoated. The ceramics were mounted in a brass water-cooled holder with a thermal conductive paste and cooled with 16 °C water.

For pumping the laser ceramics two different diode lasers were available: a 55 W, broadband laser with a central operating wavelength of 976 nm and spectral width (FWHM) of 5 nm (nLight e06.0550976105) and a 9 W, narrowband VBG-stabilized laser, also emitting at 976 nm with 0.4 nm bandwidth (BWT K976A02RN). The output of both pump lasers was coupled into fibers with a 105 µm core diameter and a numerical aperture of 0.22.

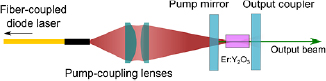

The laser setup is illustrated in figure 1. The pump light was imaged on the ceramics using two plano-convex lenses with focal lengths of 10 mm and 20 mm, making the waist diameter of the pump beam equal to 210 µm. Also, lens configurations with larger magnification factors were examined, but this resulted in lower laser efficiency. The compact optical resonator consisted of two plane mirrors spaced by 7 mm, which was the minimum distance allowed by the length of the gain medium and the mounts of the cavity mirrors. The pump mirror was highly reflective for the 2.7 µm wavelength and had 97.9% transmittance for pump radiation; the output-coupling mirror yielding optimum laser performance had reflectivity of 98.1% (other tested output couplers had reflectivity of 93.6%, 97.1%, and 98.7%).

Figure 1. The experimental setup of the Er:Y2O3 laser.

Download figure:

Standard image High-resolution imageThe output power was measured with a thermopile power meter (Ophir 3A) behind a Thorlabs FB2750-500 band-pass filter (center wavelength 2.75 µm and FWHM 0.5 µm). Spectral measurements in the 2.7 µm region were performed using an Oriel MS257 grating monochromator, a Hamamatsu C12492-210 photodiode, and a digital oscilloscope. In CW operation, the laser output was also modulated with an optical chopper. For spectrum and beam quality measurements, the divergent output beam was collimated using a 50 mm lens. The temperature of the gain medium was observed with a thermal camera (FLIR A35).

3. Experimental results

3.1. Quasi-continuous-wave (QCW) operation

The laser was first operated with pulsed pumping (1 ms pulses at 10 Hz repetition rate, 1% duty cycle) to reduce heating of the gain medium and to allow higher peak pump power. Therefore, the pump source used here was the 55 W broadband diode laser, cooled down to 15 °C to shift its central wavelength to 974 nm. The pump light absorption at low pumping level was 82%, but it increased to 90% at full pump power (measured in non-lasing conditions). This is probably partially caused by increased ESA in Er:Y2O3 during intense pumping and in part by temperature-dependent drift of the pump laser wavelength.

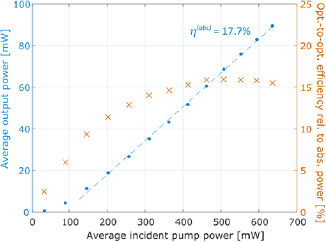

A maximum average output power of 90 mW was obtained at 636 mW of incident pump power with a slope efficiency of 17.7% with respect to the absorbed power (see figure 2). The maximum temperature of the ceramics rose to 37 °C. The corresponding peak power of roughly 9 W (and even significantly higher during relaxation oscillations at the start of each pulse) in a beam with very small diameter led to damage of the pumped faces of the ceramics on several occasions.

Figure 2. Laser output power (in blue dots) and optical-to-optical efficiency with respect to the absorbed pump power (orange crosses) in the QCW regime with 1 ms pump pulses at 10 Hz repetition rate.

Download figure:

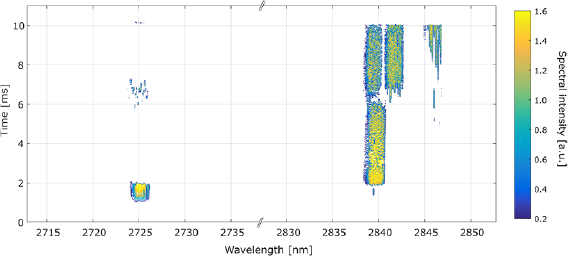

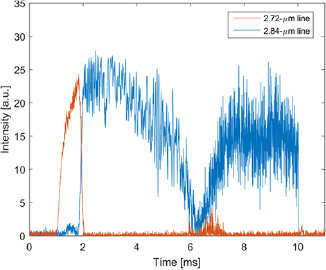

Standard image High-resolution imageWith 1 ms pump pulse duration, the lasing wavelength was 2725 nm. However, when operating with longer, 10-ms pump pulses, the wavelength shifted to 2840 nm, 2842 nm, and 2846 nm lines after 1 ms of laser emission (as shown in figures 3 and 4). This can be explained by an increasing population of the 4I13/2 manifold during the pumping process, and thus increased re-absorption. The laser therefore switched to a transition less affected by re-absorption. This behavior was not observed in CW operation due to significantly lower pump intensity.

Figure 3. A spectrogram of laser output in QCW operation with 10 ms pump pulses at 2 Hz repetition rate (pumping starts at a time of 0 ms) at a pump power of 310 mW (peak pump power of 62 W).

Download figure:

Standard image High-resolution imageFigure 4. The temporal pulse shape in QCW operation with 10 ms pump pulses (same data as in figure 3). The emission at 2725 nm is shown in orange, and emission at 2840–2846 nm is shown in blue.

Download figure:

Standard image High-resolution image3.2. Continuous-wave operation

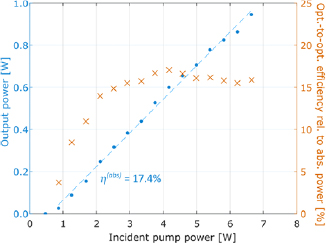

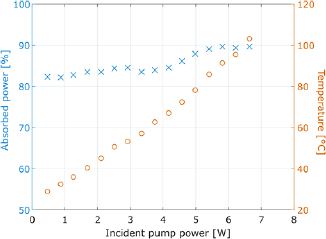

For CW operation, the 9 W wavelength-stabilized narrowband pump diode laser was used. Figure 5 shows the laser performance of Er:Y2O3 under continuous pumping in terms of output power and optical-to-optical efficiency versus incident pump power. The lasing threshold was 0.72 W of incident pump power and the generated output power was increased to 0.95 W at an incident pump power of 6.64 W (optical-to-optical efficiency of 14.3%) with a slope efficiency of 16.0% (17.4% related to absorbed pump power). Further increment of the pump power did not lead to an increase in output power. Pump absorption under non-lasing conditions increased with pump power from 82% to 90% (see figure 6), similarly to with QCW operation. The maximum temperature of the ceramics increased up to 103 °C at 6.6 W pump power, but no damage of the gain medium was observed in the CW regime.

Figure 5. Laser output power (blue dots) and optical-to-optical efficiency related to absorbed pump power (orange crosses) in CW operation. The slope efficiency indicated here is also related to the absorbed pump power.

Download figure:

Standard image High-resolution imageFigure 6. The absorbed pump power (blue crosses) and maximum temperature (orange circles) of the gain medium for various pump power levels.

Download figure:

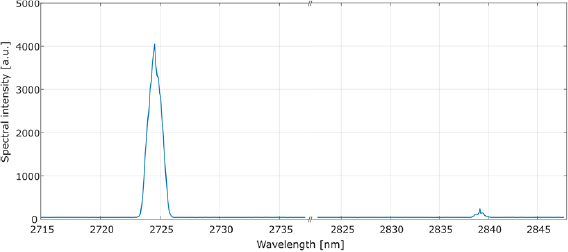

Standard image High-resolution imageThe output spectrum of the laser (see figure 7) showed a strong spectral line at 2725 nm and also a substantially weaker line at 2839 nm. There was no laser oscillation observed at any other wavelength in the CW regime.

Figure 7. The output spectrum of the Er:Y2O3 laser in CW operation at a pump power of 4 W.

Download figure:

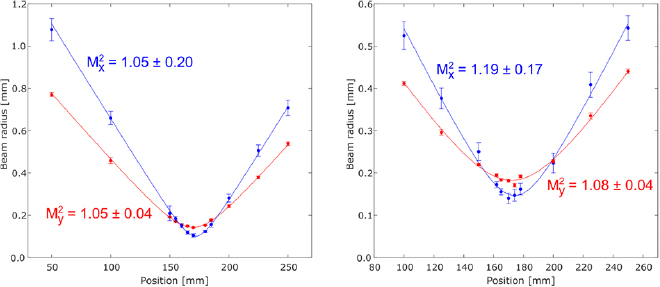

Standard image High-resolution imageBeam quality was measured using the knife-edge technique. Measurement of the beam caustics in horizontal and vertical planes was carried out for two different pump power levels—1.2 W and 4.5 W of incident pump power. The collimated output beam was focused with a 200 mm plano-convex lens and the M2 parameter was determined from multiple beam width measurements near the beam waist.

The output beam was found to be almost diffraction-limited due to an interplay between the diameter of the pumped area and the power of the thermal lens formed in the gain medium. The M2 parameters were  and

and  at low pump power and

at low pump power and  and

and  at high pump power (figure 8). The slight astigmatism and better beam quality in the vertical direction can be explained by the dimensions of the ceramic sample (a clear aperture of 1 mm in the vertical and 2 mm in the horizontal direction) and the fact that the pumped area was positioned near the bottom side of the ceramics, so the temperature profile and thermal lens were also asymmetric.

at high pump power (figure 8). The slight astigmatism and better beam quality in the vertical direction can be explained by the dimensions of the ceramic sample (a clear aperture of 1 mm in the vertical and 2 mm in the horizontal direction) and the fact that the pumped area was positioned near the bottom side of the ceramics, so the temperature profile and thermal lens were also asymmetric.

Figure 8. M2 parameter measurement of the output beam in CW operation at pump powers of 1.2 W (left) and 4.5 W (right). The horizontal beam radius is shown in blue, the vertical is shown in red.

Download figure:

Standard image High-resolution imageThe maximum output power of the laser was mainly limited by heat, and further power scaling should be possible by choosing ceramics with lower doping concentrations to better distribute the heat load along the gain medium. Also, Er:Y2O3 ceramics with a doping concentration around 7 at.% were shown to lase more effectively than 15 at.% ceramics [10]. Furthermore, laser efficiency at high pump intensity is decreased and the heat load is increased by ESA and upconversion processes (leading, e.g., to very intense green-yellowish fluorescence, observed throughout the experiment), and thus the pumped area should be expanded for higher pump power. Therefore, there is a significant potential for further enhancing the laser performance of the Er:Y2O3 ceramic laser.

4. Summary

Room temperature lasing performance of 15 at.% Er:Y2O3 ceramics at the 2.7 µm wavelength was investigated. Using pulsed pumping with 1 ms pulses, we obtained a maximum peak output power of 9 W with 1% duty cycle at a wavelength of 2725 nm. For longer pump pulses, strong lasing at 2.84 µm was observed. In CW operation we obtained an output power of 0.95 W with a slope efficiency of 17.4% (related to absorbed power), which is the highest output power from 15 at.% Er:Y2O3 ceramics and the highest efficiency in a room temperature mid-IR Er:Y2O3 laser reported to date. The output beam quality was close to the diffraction limit (M2 < 1.2), yielding the high brightness of the laser output. The Er:Y2O3 ceramics were proven to be a promising material for efficient lasing in the attractive 2.7 µm wavelength region.

Acknowledgments

This work was partially supported by JSPS KAKENHI Grant No. 15KK0245, by the Ministry of Education, Youth and Sports of the Czech Republic (Programme NPU I Project No. LO1602), by the European Regional Development Fund and the state budget of the Czech Republic (project HiLASE CoE: Grant No. CZ.02.1.01/0.0/0.0/15_006/0000674), and by the European Union's Horizon 2020 research and innovation programme under grant agreement No. 739573. The research was performed with the support and under the auspices of the National Institute for Fusion Science (KEIN1608).