Abstract

This paper describes reduction in noise, vibrations, total and tooth-to-tooth, and longwave transmission errors, total and tooth-to-tooth composite errors, and radial runout of spur gears by imparting them flank modifications and their combinations by a non-contact advanced finishing process referred to as pulsed electrolytic dissolution. Eight spur gears were modified using innovatively developed 5 cathode gears and apparatus by imparting them 5 flank modifications (i.e. tip relief, root relief, end relief, profile crowning, lead crowning) individually and their 4 selected combinations. Vibrations at all rotational speeds and noise at 900 and 1200 rpm are reduced for all modified spur gears at all the values of applied loads. End relieved spur gear showed maximum reductions in noise and vibrations by 5 dBA and 3.77 m/s2 respectively for 1200 rpm speed. Reduction amount in noise and vibrations of modified gears increase with rotary speed. Lead crowned gear showed maximum reductions of 146 µm in total transmission error, 109 µm in total composite error, and 102 µm in radial runout. End relieved gear showed maximum reductions of 37 µm in tooth-to-tooth and 139 µm longwave transmission errors. Tip relieved, and tip and root relieved gear showed maximum reduction of 121 µm in tooth-to-tooth composite error. This work proves that the developed non-contact process can very effectively impart different flank modifications individually and their combinations to spur gears without any twist error. Lead crowning, end relieving, tip relieving, and tip and root relieving are main flank modifications that significantly improve functional performance characteristics of spur gears. It will result in their enhanced operating performance and service life, which will help their manufacturers and end-users.

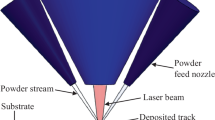

Graphical Abstract

Highlights

-

Non-contact process developed to impart 5 flank modifications and their combinations to spur gears.

-

Study on decrease in total, tooth-to-tooth, and longwave transmission error by single flank roll test.

-

Reduction study in total and tooth-to-tooth composite errors, radial runout, noise and vibrations.

-

All flank modifications of spur gears improved their functional performance characteristics.

-

Lead crowned and tip+root relieved gears yielded max reduction in double flank testing parameters.

-

End relieved gear gave max reduction in noise and vibrations and single flank testing parameters.

Similar content being viewed by others

Data availability

The authors understand that our manuscript and associated personal data will be shared with Research Square for the delivery of the author dashboard.

Code availability

No software has been developed in this manuscript.

Abbreviations

- \({{\varvec{F}}}_{{\varvec{i}}}^{\mathbf{^{\prime}}}\) :

-

Total transmission error (µm)

- \({{\varvec{f}}}_{{\varvec{i}}}^{\mathbf{^{\prime}}}\) :

-

Tooth-to-tooth transmission error (µm)

- \({{\varvec{F}}}_{{\varvec{l}}}^{\mathbf{^{\prime}}}\) :

-

Longwave tangential composite error (µm)

- \({{\varvec{F}}}_{{\varvec{i}}}^{"}\) :

-

Total composite error (µm)

- \({{\varvec{f}}}_{{\varvec{i}}}^{"}\) :

-

Tooth-to-tooth composite error (µm)

- \({{\varvec{F}}}_{{\varvec{r}}{\varvec{f}}}^{\mathbf{^{\prime}}}\) :

-

Radial runout determined from double flank roll testing (µm)

- r wp :

-

Pitch circle diameter of workpiece gear (mm)

- Z m :

-

Number of teeth in master gear

- Z w :

-

Number of teeth in workpiece gear

- θ m :

-

Angle rotated by the master gear (radians)

- θ w :

-

Angle rotated by the workpiece gear (radians)

- ΔNGi :

-

Change in noise level for ith modified gear with respect to unmodified gear (dBA)

- ΔVGi :

-

Change in vibrations for ith modified gear with respect to unmodified gear (m/s2)

References

Wang H, Tang L, Zhou C, Shi Z (2021) Wear life prediction method of crowned double helical gear drive in point contact mixed elastohydrodynamic lubrication. Wear 484–485:204041. https://doi.org/10.1016/j.wear.2021.204041

Fatourehchi E, Mohammadpour M, King PD, Rahnejat H, Trimmer G, Williams A (2018) Microgeometrical tooth profile modification influencing efficiency of planetary hub gears. Int J Powertrains 7:162–179. https://doi.org/10.1504/IJPT.2018.10011451

Neha G, Shunmugam MS (2017) Effect of shaft misalignment and mitigation through crowning in spur gear transmission. Int J Com Aided Eng Technol 9(4):385–407. https://doi.org/10.1504/IJCAET.2017.086919

Jia C, Fang Z, Yao L, Zhang J (2020) Tooth flank modification to reduce transmission error and mesh-in impact force in consideration of contact ratio for helical gears. Proc IMech Part C: J Mech Eng Sci 235(19):4475–4493. https://doi.org/10.1177/0954406220975065

Wang H, Zhou C, Hu B, Liu Z (2020) Tooth wear prediction of crowned helical gears in point contact. Proc IMech Eng Part J: J Eng Tribol 234(6):947–963. https://doi.org/10.1177/1350650119896467

Jelaska D (2012) Gears and gear drives. John Wiley & Sons Ltd. Chichester,UK https://doi.org/10.1002/9781118392393

Jain NK, Petare AC (2017) Review of gear finishing processes. In: Hashmi S (ed) Comprehensive materials finishing, Elsevier Science, Oxford (UK) 93–120 https://doi.org/10.1016/B978-0-12-803581-8.09150-5

Lange J (2009) How are you dealing with the bias error in your helical gears. Gear Technol: J Gear Manuf 26(3):47–54. https://www.geartechnology.com/ext/resources/issues/0509x/gt0509.pdf

Ren Z, Fang Z, Kizaki T, Feng Y, Nagata T, Komatsu Y, Sugita N (2022) Understanding local cutting features affecting surface integrity of gear flank in gear skiving. Int J Mach Tools Manuf 172:103818. https://doi.org/10.1016/j.ijmachtools.2021.103818

Fong ZH, Chen GH (2016) Gear flank modification using a variable lead grinding worm method on a computer numerical control gear grinding machine. Trans ASME: J Mech Des 138(8):083302. https://doi.org/10.1115/1.4033919

Yu B, Kou H, Zhao B, Shi Z, Sun Y, Wu G (2021) Approximation model for longitudinal-crowned involute helical gears with flank twist in continuous generating grinding. Int J Adv Manuf Technol 114(11):3675–3694. https://doi.org/10.1007/s00170-021-07099-y

Tian X, Li D, Huang X, Liu H, Han J, Xia L (2022) A topological flank modification method based on contact trace evaluated genetic algorithm in continuous generating grinding. Mech Mach Theory 172:104820. https://doi.org/10.1016/j.mechmachtheory.2022.104820

Hsu RH, Wu YR, Tran VT (2019) Manufacturing helical gears with double-crowning and twist-free tooth flanks using a variable pressure angle shaving cutter. Proc IMech Eng Part B: J Eng Manuf 233(1):77–86. https://doi.org/10.1177/0954405417718590

Han J, Zhu Y, Xia L, Tian X (2018) A novel gear flank modification methodology on internal gearing power honing gear machine. Mech Mach Theory 121:669–682. https://doi.org/10.1016/j.mechmachtheory.2017.11.024

Wu YR, Tran VT (2015) Lead crowning and anti-twist for tooth flank of a heat treated helical gear on internal CNC honing machine. App Mechanics Mater 799–800:554–559. https://doi.org/10.4028/www.scientific.net/AMM.799-800.554

Zheng F, Zhang M, Zhang W, Guo X (2018) Research on the tooth modification in gear skiving. Trans ASME: J Mech Des 140(8):084502. https://doi.org/10.1115/1.4040268

Tran VT, Hsu RH, Tsay CB (2014) Study on the anti-twist helical gear tooth flank with longitudinal tooth crowning. Trans ASME: J Mech Des 136(6):061007. https://doi.org/10.1115/1.4027166

Terauchi Y, Nadano H, Nohara M (1982) On the effect of the tooth profile modification on the dynamic load and the sound level of the spur gear. Bulletin JSME 25(207):1474–1481. https://doi.org/10.1299/jsme1958.25.1474

Chong TH, Myong JH, Kim KT (2001) Tooth modification of helical gears for minimization of vibration and noise. Int J Preci Eng Manuf 2(4):5–11. https://www.koreascience.or.kr/article/JAKO200111920887791.page

Mao K (2006) An approach for powertrain gear transmission error prediction using the non-linear finite element method. Proc IMech Eng Part D: J Auto Eng 220(10):1455–1463. https://doi.org/10.1243/09544070JAUTO251

Li S (2007) Effects of machining errors, assembly errors and tooth modifications on loading capacity, load-sharing ratio and transmission error of a pair of spur gears. Mech Mach Theory 42(6):698–726. https://doi.org/10.1016/j.mechmachtheory.2006.06.002

Tesfahunegn YA, Rosa F, Gorla C (2010) The effects of the shape of tooth profile modifications on the transmission error, bending, and contact stress of spur gears. Proc IMech Eng Part C: J Mech Eng Sci 224(8):1749–1758. https://doi.org/10.1243/09544062JMES1844

Ma H, Yang J, Song R, Zhang S, Wen B (2014) Effects of tip relief on vibration responses of a geared rotor system. Proc IMech Eng Part C: J Mech Eng Sci 228(7):1132–1154. https://doi.org/10.1177/0954406213500615

Ghosh SS, Chakraborty G (2016) On optimal tooth profile modification for reduction of vibration and noise in spur gear pairs. Mech Mach Theory 105:145–163. https://doi.org/10.1016/j.mechmachtheory.2016.06.008

Yang J, Zhang H, Li T, Gao Z, Nie S, Wei B (2018) A profile dressing method for grinding worm used for helical gear with higher order modification profile. Int J Adv Manuf Technol 99:161–168. https://doi.org/10.1007/s00170-018-2459-y

Pang GB, Xu WJ, Zhou JJ, Li DM (2010) Gear finishing and modification compound process by pulse electrochemical finishing with a moving cathode. Adv Mater Res 126–128:533–538. https://doi.org/10.4028/www.scientific.net/AMR.126-128.533

McGeough JA (1988) Advanced methods of machining. Springer, Netherlands, Netherlands

Pathak S, Jain NK, Palani IA (2015) On surface quality and wear resistance of straight bevel gears finished by pulsed electrochemical honing process. Int J Electrochem Sci 10(11):8869–8885. http://www.electrochemsci.org/papers/vol10/101108869.pdf

Pueo M, Santolaria J, Acero R, Gracia A (2017) A review of tangential composite and radial composite gear inspection. Preci Eng 50:522–537. https://doi.org/10.1016/j.precisioneng.2017.05.007

Arteta MP, Mazo JS, Cacho RA, Arjol GA (2013) Double flank roll testing machines intercomparison for worm and worm gear. Procedia Eng 63:454–462. https://doi.org/10.1016/j.proeng.2013.08.231

Rana V, Petare A, Jain NK, Parey A (2022) Using abrasive flow finishing process to reduce noise and vibrations of cylindrical and conical gears. Proc IMech Eng Part B: J Eng Manuf 236(10):1341–1354. https://doi.org/10.1177/09544054221075875

Yu B, Kl T (2016) Compensated conjugation and gear tooth modification design. Trans ASME: J Mech Des 138(7):073301. https://doi.org/10.1115/1.4032264

Acknowledgements

The authors acknowledge DST-FIST Center of Excellence in Gear Engineering at IIT Indore and other labs for providing the research facilities for the present work. The first author wishes to thank the Department of Science and Technology (DST), Govt. of India, for funding him as DST-INSPIRE Research Fellow to pursue this research work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Planning design and conduct of experiments, data collection, and analysis were performed by Vivek Rana. The first draft of the manuscript was written by Vivek Rana. Prof. Neelesh Kumar Jain and Dr. Sunil Pathak commented on the previous versions of the manuscript. All authors approved the final manuscript.

Corresponding author

Ethics declarations

Consent for publication

All the authors have given their consent for the publication of this manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rana, V., Jain, N.K. & Pathak, S. Improving functional performance characteristics of spur gears through flank modifications by non-contact advanced finishing process. Int J Adv Manuf Technol 124, 1787–1811 (2023). https://doi.org/10.1007/s00170-022-10566-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10566-9