Abstract

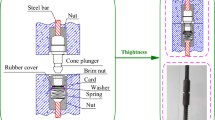

This paper proposed a replaceable friction-type artificial plastic hinge (FAPH) to connect the prefabricated concrete members, characterized by direct load transmission and streamlined configuration. The FAPH device replaced the beam-end plastic hinge region in the precast structures, which could protect the concrete joint core area and other concrete components. The experiment of a precast beam–column connection with FAPH and a cast-in-situ beam–column connection was carried out. The experimental results showed that the FAPH connection had better hysteresis performances with higher bearing capacity, energy dissipation, and ductility than the cast-in-situ concrete connection. Moreover, the finite element model was calibrated and employed to perform parametric analyses, including the axial load ratio, the friction factor, the bolt preload, and the initial clearance. The FE analysis results showed that the FAPH connection would have a more attenuation of the friction force under the higher axial load ratio. Besides, the seismic performance of FAPH can be effectively improved with the increase of the friction factor and the bolt preload, and the FAPH connection exhibited a stable performance with various initial clearances. Based on the parametric analysis results, the formulas for the yield and peak bending moment capacity for the FAPH device were proposed.

Similar content being viewed by others

References

Yee AA. Structural and economic benefits of precast/prestressed concrete construction. PCI J. 2001;46:34–43.

Yee AA. Social and environmental benefits of precast concrete technology. PCI J. 2001;46:14–9.

Wang CL, Liu Y, Zheng XL, Wu J. Experimental investigation of a precast concrete connection with all-steel. Eng Struct. 2019;178:298–308.

Lacerda MMS, da Silva TJ, Alva GMS, de Lima MCV. An experimental analysis is the influence of the vertical grouting in the interface between corbel and beam in beam-to-column connections of precast concrete structures. Eng Struct. 2018;172:201–13.

Parastesh H, Hajirasouliha I, Ramezani R. A new ductile moment-resisting connection for precast concrete frames in seismic regions: an experimental investigation. Eng Struct. 2014;70:144–57.

Zhao B, Taucer F, Rossetto T. Field investigation on the performance of building structures during the 12 May. Eng Struct. 2009;31:1707–23.

Korkmaza HH, Tankut T. Performance of a precast concrete beam-to-beam connection subject to reversed cyclic loading. Eng Struct. 2005;27:1392–407.

Park R. Seismic design and construction of precast concrete buildings in New Zealand. PCI J. 2002;47(5):60–75.

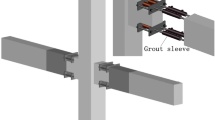

Liu HT, Yan QS, Du XL. Study of seismic performance of reinforced concrete frame beam–column joints connected with grouted sleeves. J Build Struct. 2017;38(09):54–61 (in Chinese).

Zhao ZZ, Han WL, Qian JR, Liu SW, Wang YY. Experimental study on seismic behavior of assembled monolithic beam–column interior joints with rebar spliced by pressed sleeve. J Build Struct. 2017;38(04):45–53 (in Chinese).

Im HJ, Park HG, Eom TS. Cyclic loading test for reinforced-concrete-emulated beam–column connection of precast concrete moment frame. ACI Struct J. 2013;110(1):115–125.

Hosseini SJA, Rahman ABA, Osman MH, Saim A, Adnan A. Bond behavior of spirally confined splice of deformed bars in grout. Constr Build Mater. 2015;80:180–94.

Lu ZW, Huang J, Dai SB, Liu JX, Zhang MZ. Experimental study on a precast beam–column joint with double grouted splice sleeves. Eng Struct. 2019;199: 109589.

Yan QS, Zhang YN. Study on seismic performance of aprecast concrete beam–column connection with grout sleeves. Concrete. 2021;11:135–40 (in Chinese).

Choi HK, Choi YC, Choi CS. Development and testing of precast concrete beam-to-column connections. Eng Struct. 2013;56:1820–35.

Deng MK, Ma FD, Ye W, Yin PF. Experimental study on a seismic behavior of locally used HDC assembled frame beam–column joints. Eng Mech. 2019;36(9):68–78 (in Chinese).

Wang H, Marino EM, Panc P, Liu H, Nie X. Experimental study of a novel precast prestressed reinforced concrete beam-to-column joint. Eng Struct. 2018;156:68–81.

Zhang JX, Ding CL, Rong X, Yang HW, Li YY. Development and experimental investigation of hybrid precast concrete beam–column joints. Eng Struct. 2020;219: 110922.

Morgen BG, Kurama YC. Seismic design of friction-damped precast concrete frame structures. J Struct Eng. 2005;131(11):1501–11.

Vidjeapriya R, Jaya KP. Experimental study on two simple mechanical precast beam–column connections under reverse cyclic loading. J Perform Constr Facil. 2013;27:402–14.

Wu CX, Lai WS, Zhou Y, Zhang C, Deng XS. Experimental study on seismic behaviors of new energy-dissipative prefabricated concrete frame structure joints. China Civ Eng J. 2015;48(9):24–30. (in Chinese).

Belleri A, Marini A, Riva P, Nascjmbene R. Dissipating and re-centring devices for portal-frame precast structures. Eng Struct. 2017;150:736–45.

Li ZH, Qi Y, Teng J. Experimental investigation of prefabricated beam-to-column steel joints for precast concrete structures under cyclic loading. Eng Struct. 2020;209: 110217.

Ma ZH, Zhang JG, Liang HZ, Li LY. Numerical research on prefabricated frame joint based on artificial dissipative plastic hinge under low-reversed loading. China Civ Eng J. 2020;53(S2):162–8 (in Chinese).

Xie L, Wu J, Zhang J, Liu CY. Experimental study of mechanical properties of beam–column joint of a replaceable energy-dissipation connector-precast concrete frame. J Build Eng. 2021;43: 102588.

Hu G, Huang W, Xie H. Mechanical behavior of a replaceable energy dissipation device for precast concrete beam–column connections. J Constr Steel Res. 2020;164: 105816.

Li DB, Wu CX, Zhou Y, Luo WL, Lie WC. A precast beam–column connection using metallic damper as connector: experiment and application. J Constr Steel Res. 2021;181:106628.

Ye M, Jiang J, Chen HM, Zhou HY, Song DD. Seismic behavior of an innovative hybrid beam–column connection for precast concrete structures. Eng Struct. 2021;227:111436.

Yang CT, Li AQ, Xie LL. Development of design method for precast concrete frame with dry-connected rotational friction dissipative beam-to-column joints. J Build Eng. 2022;45: 103563.

Qi A, Liu XH, Xu RJ, Yan XY. A precast beam–column joint using an innovative friction damper as a connector: experimental and numerical study. Structures. 2022;35:968–89.

Xu GW, Ou JP. Seismic performance of combined rotational friction and flexural yielding metallic dampers. J Build Eng. 2022;49:104059.

GB 50068-2018. Unified stand for reliability design of building structures. Beijing: China Building Industry Press; 2018. (in Chinese).

Zhong J, Yang T, Pang YT, Yuan WC. A novel structure-pulse coupled model for quantifying the column ductility demand under pulse-like GMs. J Earth Eng. 2021;1–19.

Zhong J, Ni M, Hu HM, Yuan WC, Yuan HP, Pang YT. Uncoupled multivariate power models for estimating performance-based seismic damage states of column curvature ductility. Structures. 2022;36:752–64.

Weng YH, Qian K, Fu F, Fang Q. Numerical investigation on load redistribution capacity of flat slab substructures to resist progressive collapse. J Build Eng. 2020;29: 101109.

Qian K, Geng SY, Liang SL, Fu F, Yu J. Effects of loading regimes on the structural behavior of RC beam–column sub-assemblages against disproportionate collapse. Eng Struct. 2022;251: 113470.

Huang H, Yuan YJ, Zhang W, Li M. Seismic behavior of a replaceable artificial controllable plastic hinge for precast concrete beam–column joint. Eng Struct. 2021;245: 112848.

GB/T 50081-2019. Standard for test methods of concrete physical and mechanical propertied. Beijing: China Building Industry Press; 2019. (in Chinese).

GB/T 1231-2006. Specifications of high strength bolts with large hexagon head, large hexagon nuts, plain washers for steel structures. Beijing: China Building Industry Press; 2006. (in Chinese).

GB/T 228-2002. Metalic materials-tensile testing at ambient temperature. Beijing: China Building Industry Press; 2002. (in Chinese).

Shen PS. Concrete structure design. Beijing: Higher education press; 2012. (in Chinese).

GB 50017-2017. Code for design of steel structure. Beijing: China Building Industry Press; 2017. (in Chinese).

Nie JG, Qing K, Liu R. Experimental study on seismic behavior of connections composed of concrete-filled square steel tubular columns and steel concrete composite beams with interior diaphragms. J Build Struct. 2006;27(4):1–9 (in Chinese).

Chan RW, Albermani F. Experimental study of steel slit damper for passive energy dissipation. Eng Struct. 2008;30:1058–66.

GB 50010-2010. Code for design of concrete structures. Beijing: China Building Industry Press; 2010. (in Chinese).

Shi YJ, Wang M, Wang YQ. Experimental study of structural steel constitutive relationship under cyclic loading. J Build Mater. 2012;15(3):293–300 (in Chinese).

Strand H. Design, Testing and Analysis of Journal Bearing of Construction Equipment. Stockholm: Royal Institute of Technology; 2005.

Zhang T, Wang NC, Cheng X, Jiang F. The comparison research on design methodology of pins. J Mech Strength. 2015;37(3):461–6 (in Chinese).

Ji Y. Numerical analysis of the bearing capacity of pin connections used in steel-box girders. Struct Eng. 2014;30(3):99–104 (in Chinese).

Xun ZL. Elasticity (volume 2 of 2). Beijing: Higher Education Press; 2016. (in Chinese).

Acknowledgements

This work described in this paper was supported by the National Natural Science Foundation of China (51778060), the Natural Science Foundation of Shaanxi Province (2020KW-067), the Natural Science Foundation of Fujian Province (2021J011062), and the Fundamental Research Funds for the Central Universities, CHD (nos. 300102289401, 300102280711 and 300102280713).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical statement

The authors state that the work was conducted according to ethical standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, H., Li, M., Zhang, W. et al. Seismic behavior of a friction-type artificial plastic hinge for the precast beam–column connection. Archiv.Civ.Mech.Eng 22, 201 (2022). https://doi.org/10.1007/s43452-022-00526-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00526-1